Automatic correction production equipment and method for automatic production of transformer grounding wire

A technology of automatic calibration and production equipment, applied in the direction of transformer/inductor coil/winding/connection, inductance/transformer/magnet manufacturing, preventing/reducing unnecessary electric/magnetic influence, etc., can solve the automation degree of transformer grounding wire Low, unable to realize automatic production of transformer grounding wire, automatic correction, automatic dispensing and other issues, to achieve the effect of elongating the dispensing position, ensuring product quality and increasing the dispensing amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

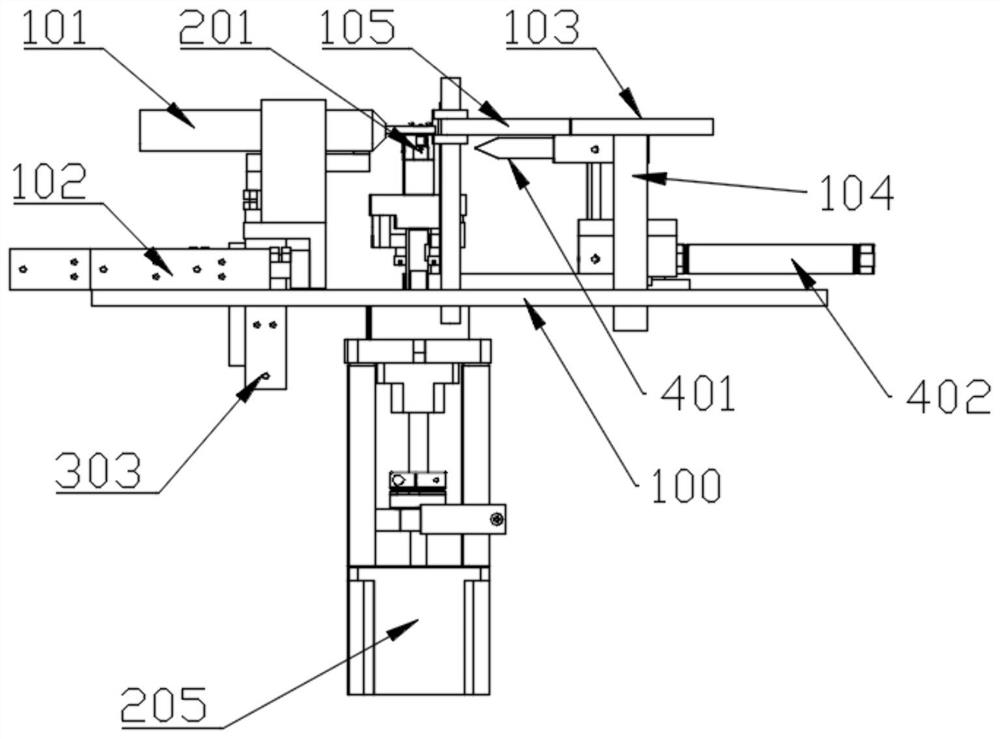

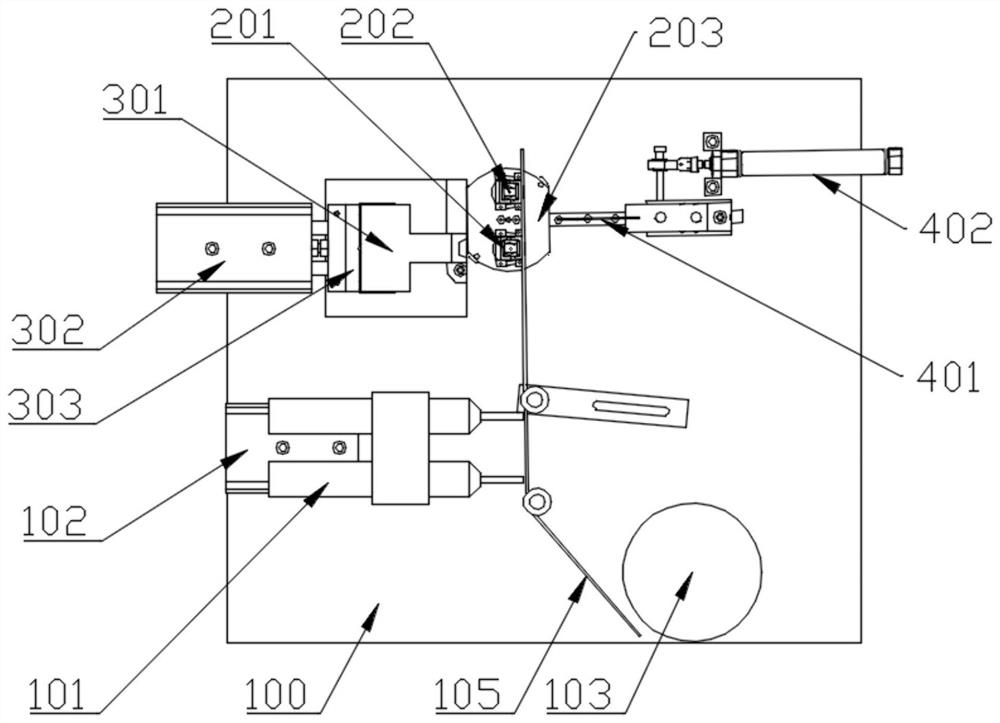

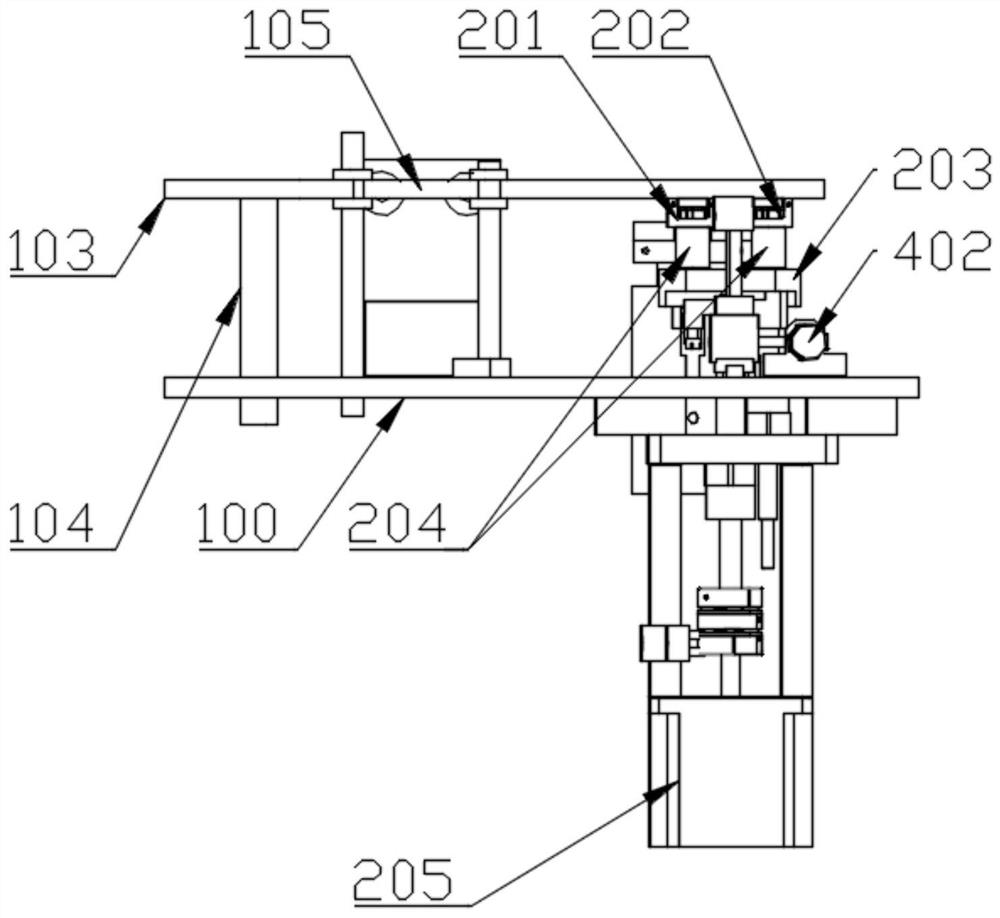

[0041] see Figure 1 to Figure 4 As shown, the embodiment of the present invention provides automatic correction production equipment for automatic production of transformer grounding wires, including:

[0042] Glue dispensing unit, the glue dispensing unit includes a glue dispensing controller 101 and an insulating tape tray, the glue dispensing controller 101 includes a transparent rubber tube, conductive glue is arranged in the transparent rubber tube, and the transparent rubber tube can display the remaining conductive glue. There is an air inlet pipe at one end of the transparent rubber cylinder, and a control valve at the other end of the transparent rubber cylinder. The control valve is used to control the amount of glue dispensed. The compressed gas in the air inlet pipe pushes the conductive glue in the transparent rubber cylinder through the control valve and spreads on it. insulating tape 105 on. The insulating tape tray is used to fix the rolled insulating tape 10...

Embodiment 2

[0052] see Figure 1 to Figure 4 As shown, the embodiment of the present invention provides automatic calibration production equipment for automatic production of transformer grounding wires. The difference between this embodiment and Embodiment 1 is that two groups of dispensing controllers 101 are provided, and two groups of dispensing controllers 101 are provided along the insulation The length direction of the adhesive tape 105 is set, and two groups of dispensing controllers 101 are used to increase the application length of the conductive adhesive, even when the ground wire is slightly deviated, it can ensure that the conductive adhesive on the insulating tape 105 is aligned with the ground wire, and the conductive adhesive Wrapped around the transformer's core along with the ground wire. The glue dispensing controller 101 is provided with a first cylinder 102, and the first cylinder 102 is used to push the glue dispensing controller 101 to move towards and away from the...

Embodiment 3

[0055] see Figure 1 to Figure 4 As shown, the embodiment of the present invention provides automatic calibration production equipment for automatic production of transformer grounding wires. The difference between this embodiment and Embodiment 1 is that the rotating device is provided with a first motor 204, and the first motor 204 is provided with two, two A first motor 204 is used to respectively drive the first clamp 201 and the second clamp 202 to rotate, and the first clamp 201 and the second clamp 202 wrap the insulating tape 105 on the transformer through rotation. The bottom of the turntable 203 is provided with a second motor 205, the second motor 205 drives the first clamp 201 and the second clamp 202 to rotate synchronously, and the second motor 205 is used to reverse the positions of the first clamp 201 and the second clamp 202 to realize the reverse adjustment of the first clamp 201 and the second clamp 202. Transformer positions on the first fixture 201 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com