A method for hybrid integration of heterogeneous materials with different sizes

A hybrid integration, heterogeneous material technology, used in electrical components, circuits, semiconductor/solid-state device manufacturing, etc., can solve problems such as difficult to achieve bonding interface holes and bonding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. It should be understood by those skilled in the art. What is specifically described below is illustrative rather than restrictive. In order not to obscure the essence of the present invention, well-known methods and procedures have not been described in detail.

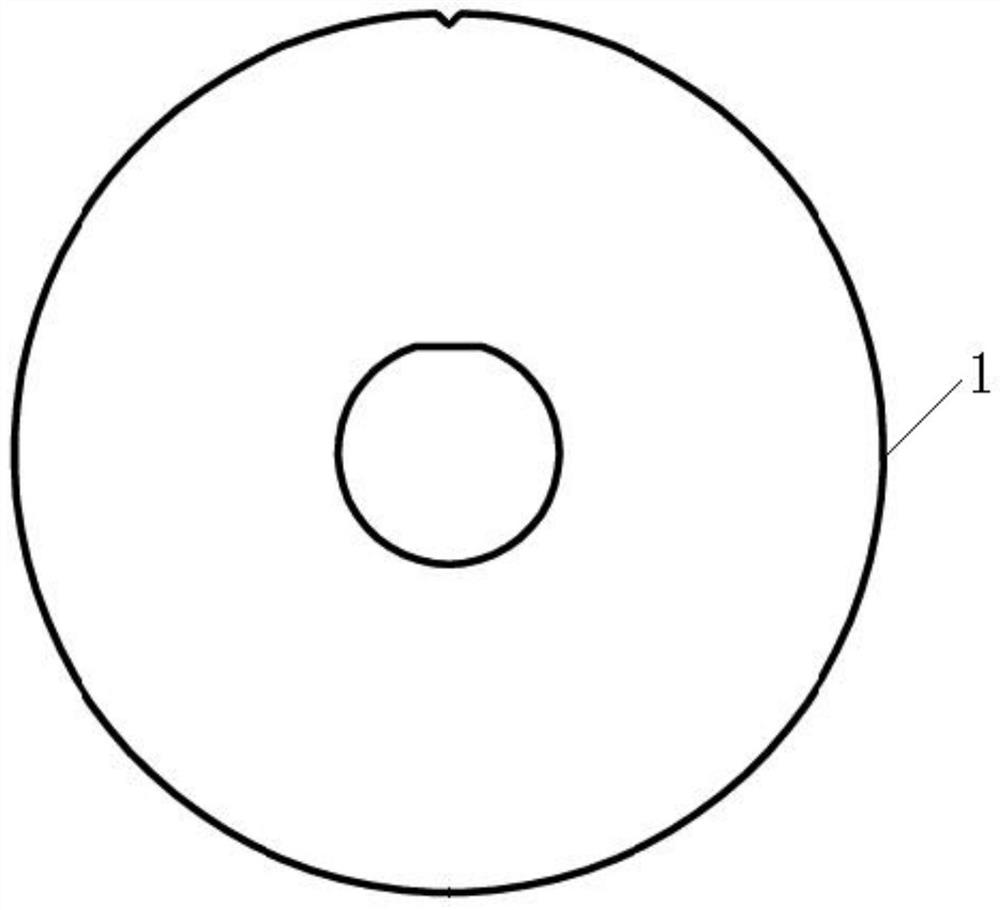

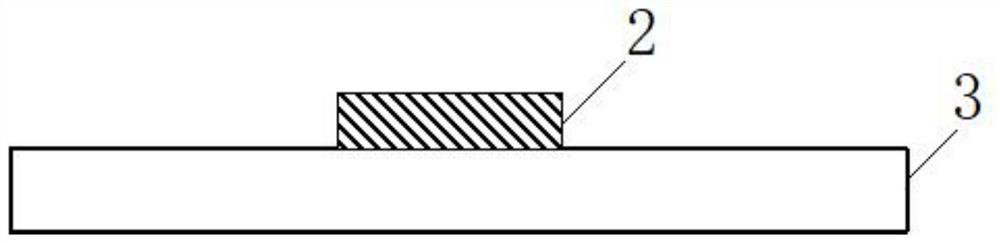

[0027] The present invention aims to complete the bonding of 2-inch wafers and 8-inch wafers by using molds, such as figure 1 ,figure 2, image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, a method for mixing and integrating heterogeneous materials of different sizes includes the following steps, and the following steps are performed in sequence:

[0028] Step 1. Take a 2-inch wafer 2 and install it in the cutting hole opened in the middle of the mold 1. The material used in the mold 1 is ceramics. Take an 8-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com