Blind buried hole printed circuit board and manufacturing method thereof

A technology of printed circuit boards and manufacturing methods, which is applied in the direction of printed circuit manufacturing, printed circuits, printed circuits, etc., can solve the problems of line width/spacing requirements, inability to make dense lines, and inability to guarantee reliability, so as to reduce plating Copper times, reduce the outer layer copper thickness, improve the effect of line density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

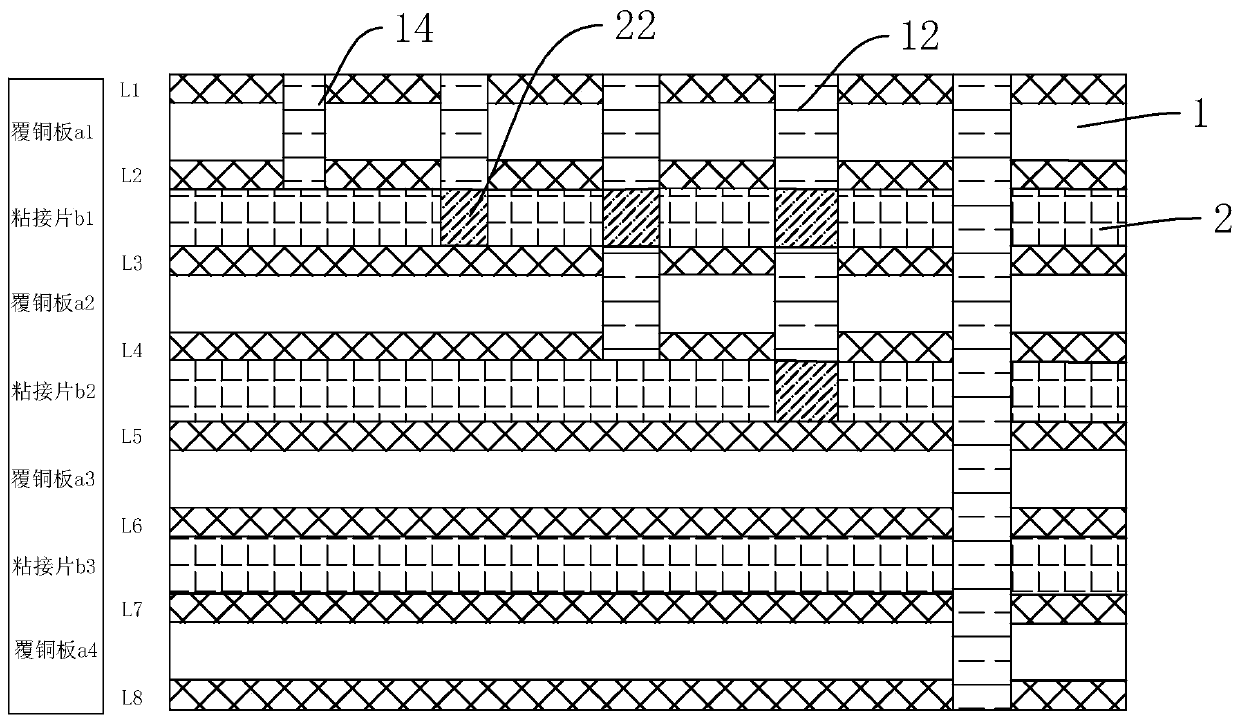

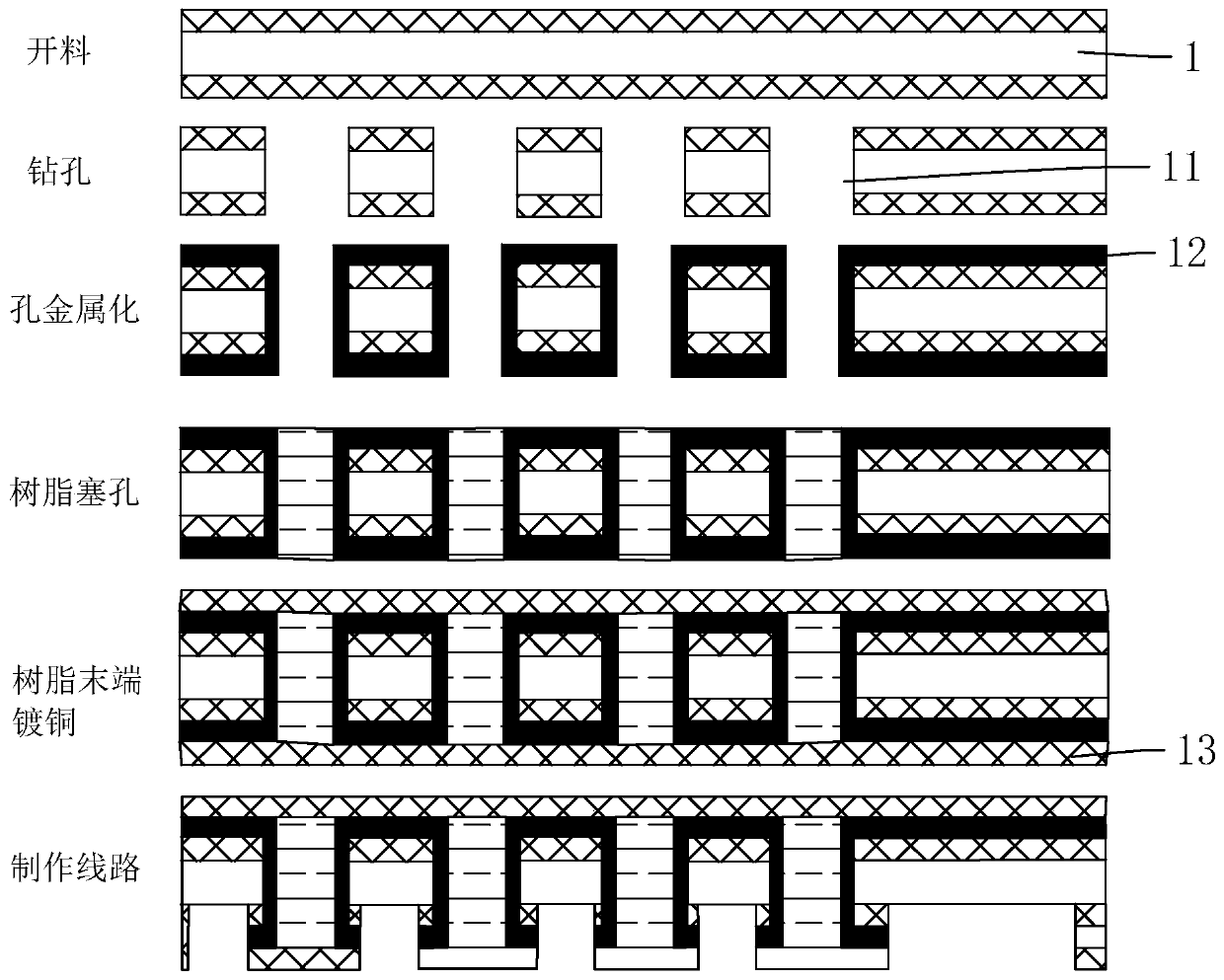

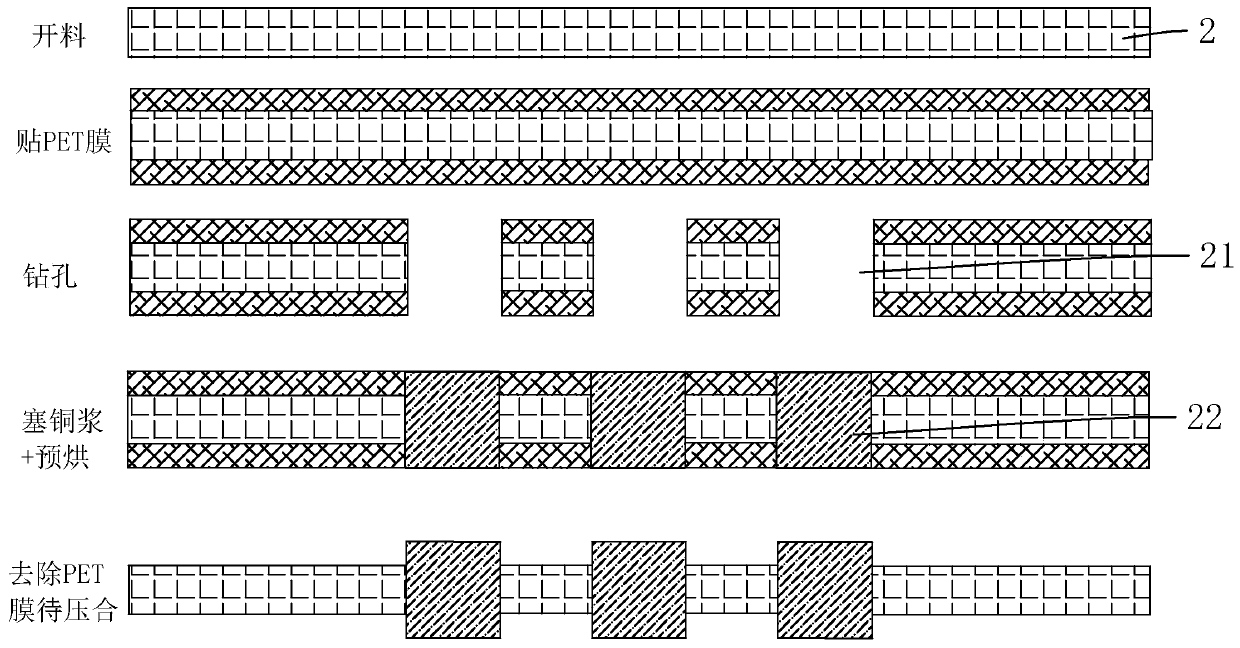

[0029] Such as figure 1 Shown is a printed circuit board with blind buried vias of the present invention, including: four-layer copper clad laminates 1 stacked in sequence and three-layer adhesive sheets 2 arranged between two adjacent layers of copper clad laminates, and the copper clad laminates are provided with The first opening 11, the adhesive sheet is provided with a second opening 21 corresponding to the first opening 11, the first opening 11 is filled with a resin column 14, the inner wall of the first opening 11 and the resin column 14 are arranged There is a first metal layer 12, the end of the resin column 14 is covered with a second metal layer 13, the first metal layer 12 is connected to the second metal layer 13, the second opening 21 is filled wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com