Method for improving quality of walnut oil

A walnut oil quality technology, which is applied in the field of oleochemicals, can solve the problems of limited addition amount, failure to use TBHQ and cane fruit oil's strong antioxidant properties, and inability to effectively slow down the oxidation rate of walnut oil, so as to prolong the shelf life and slow down the oxidation rate of walnut oil. Effect of Oxidation Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

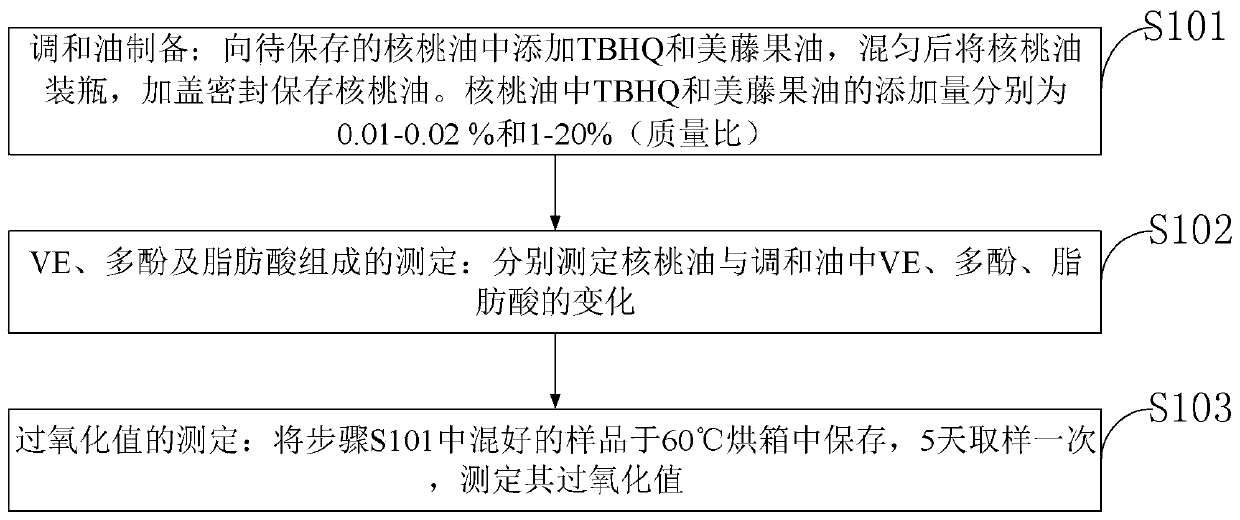

Method used

Image

Examples

Embodiment 1

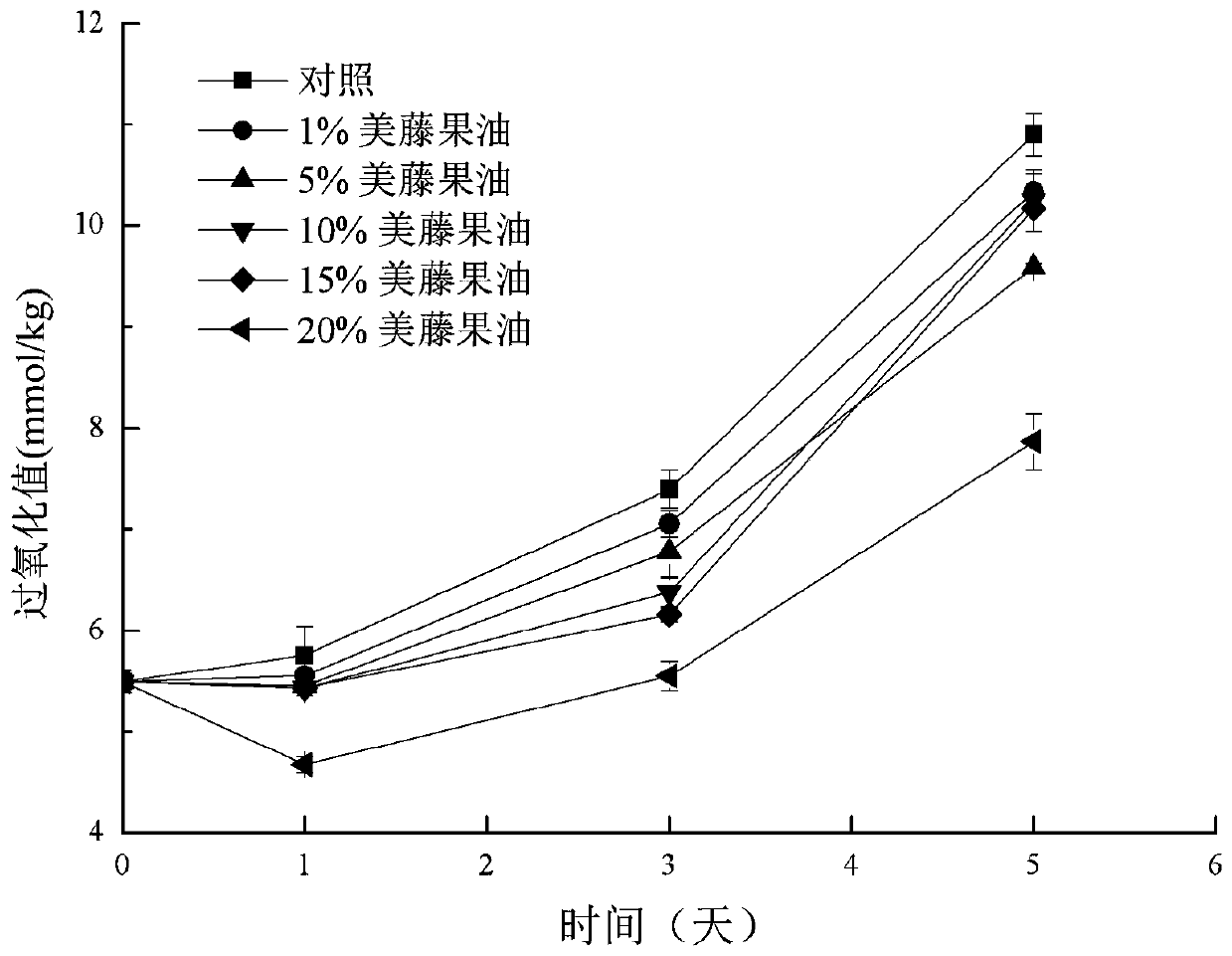

[0051] Weigh a certain amount of walnut oil, mix 20% Miteng fruit oil into the walnut oil, and emulsify it by ultrasonic method. The ultrasonic frequency is 40±1KHz, the power is 800W, and the temperature is controlled to 22±3°C to ensure uniform mixing. The composition of vitamin E, polyphenols and fatty acids were determined according to the first method in GB5009.82-2016, LS / T6119-2017, and GB5009.168-2016.

[0052] Results: The content of unsaturated fatty acids in the blended oil was high and 90%. The content of vitamin E and total polyphenols were 4.23mg / 100g and 6.19mg / kg, respectively.

[0053] Comparative example

[0054] A method to extend the shelf life of walnut oil, the specific steps are as follows:

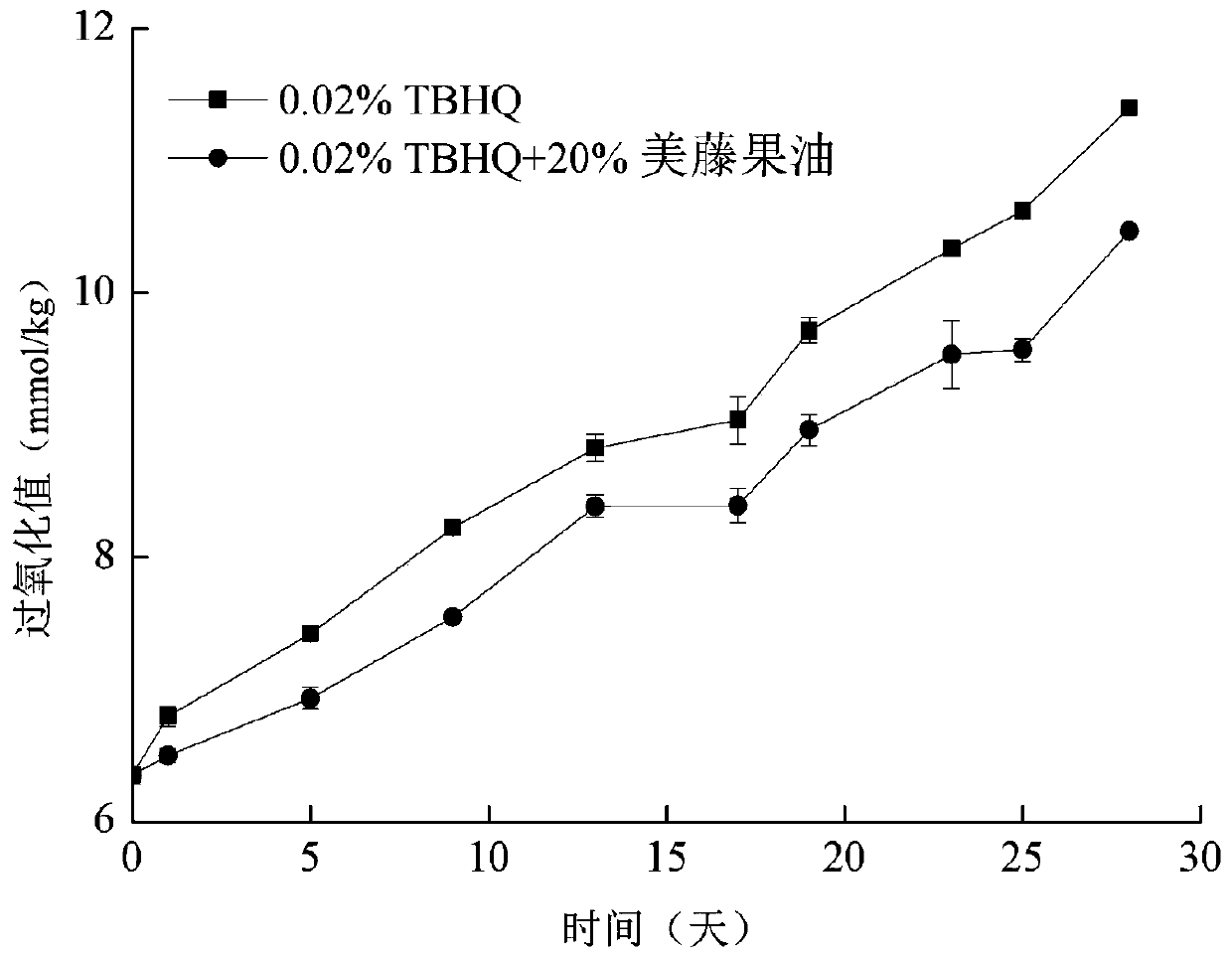

[0055] Weigh 100g walnut oil for later use. Weigh 0.02% TBHQ of the oil weight and add it to the spare walnut oil. The walnut oil was put into a light-proof sealed glass bottle and placed in an oven at 60°C to perform an accelerated experiment on the fat. This group serve...

Embodiment

[0058] The embodiment of the present invention provides a method for extending the shelf life of walnut oil, and the specific steps are as follows:

[0059] Weigh 100g walnut oil for later use. Weigh 0.02% TBHQ and 20% Miteng fruit oil by weighing oil and add them to the spare walnut oil. The walnut oil was put into a light-proof sealed glass bottle and placed in an oven at 60°C to perform an accelerated experiment on the fat. This group was used as the experimental group. The peroxide value of walnut oil in the experimental group was measured every 5 days, and the peroxide value was determined with reference to GB / T5009.227-2016 food peroxide value. The physical and chemical index limit of peroxide value refers to the peroxide value of GB / T2716-2018 vegetable oil.

[0060] Results: In an oven at 60°C, walnut oil with 0.02% TBHQ and 20% Miteng fruit oil added to reach the limit of the peroxide value of vegetable oil at 9.85 mmol / kg on the 26th day.

[0061] The above experimental ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com