A connector automatic assembly equipment

An automatic assembly and connector technology, applied in the direction of assembly machines, packaging automatic control, metal processing equipment, etc., can solve the problems of low precision, low work efficiency, low yield rate, etc., to improve the success rate of assembly and high work efficiency , The effect of low defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

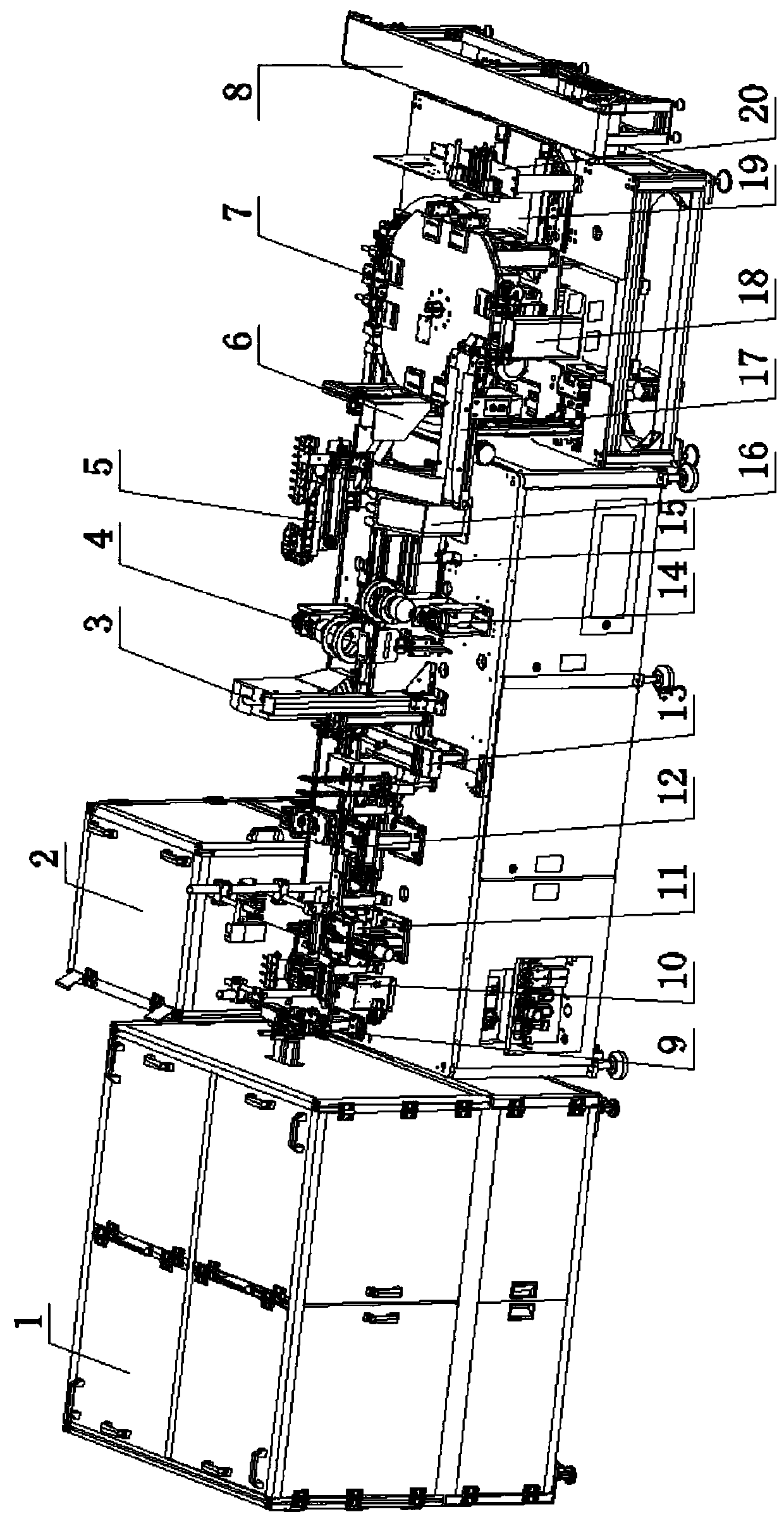

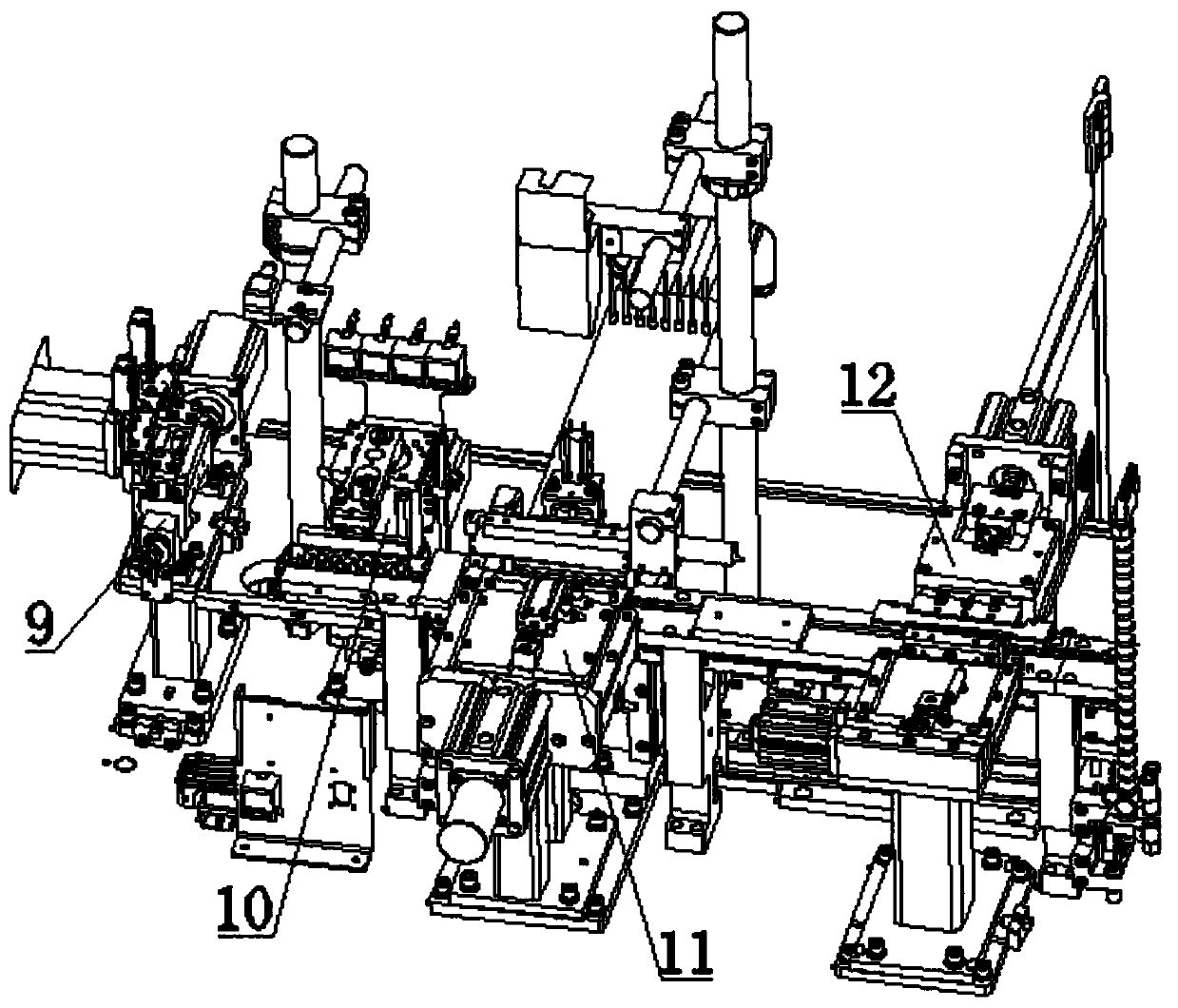

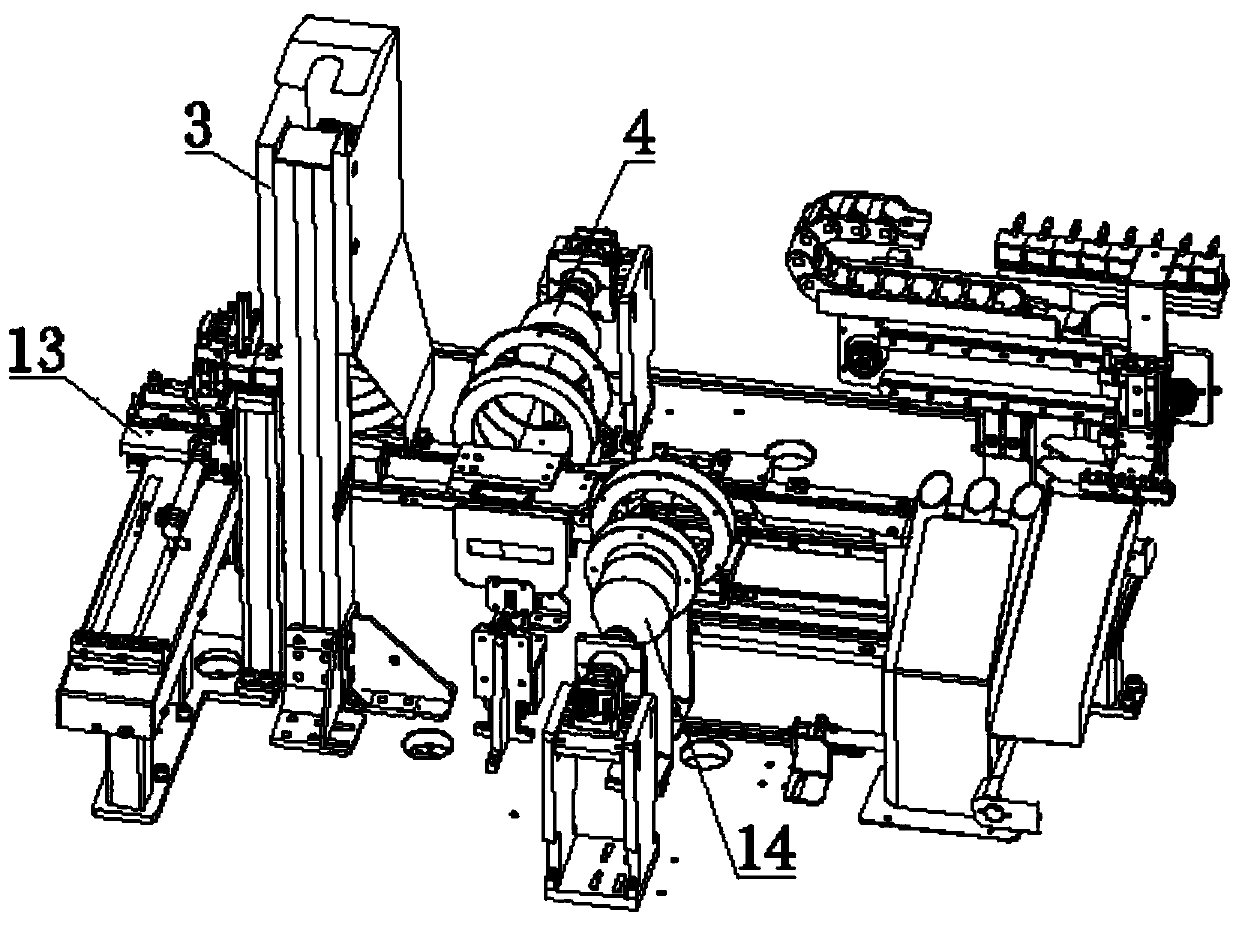

[0054] Such as figure 1 , figure 2 , Figure 5 , Figure 6 , Figure 7 , Figure 10 shown, where figure 1 It is a schematic diagram of the overall equipment assembly of the present invention, figure 2 An enlarged view of the automatic assembly part assembly, Figure 5 For the enlarged figure of the flipped part, Figure 6 Enlarged view for the horizontal rotation part, Figure 7 It is the enlarged picture of the pre-interpolation part, Figure 10 Enlarged view of the final insert.

[0055] In this embodiment, the plastic parts enter the turning part through the first feeder, and after the plastic parts are clamped and fixed by the turning part, the turning motor is driven to rotate, and the vertically arranged plastic parts are arranged horizontally to realize the turning over in the vertical direction After passing through the turning part, the qualified plastic parts go to the horizontal rotating part. After the suction cup on the horizontal rotating part absorbs...

Embodiment 2

[0072] Such as figure 1 , Figure 4 , Figure 11 , Figure 13 shown, where figure 1 It is a schematic diagram of the overall equipment assembly of the present invention, Figure 4An enlarged view of the automatic packaging part assembly, Figure 11 An enlarged view of the PP transmission part, Figure 13 Zoom in for feeders, scales, and fusers.

[0073] In this embodiment, after the assembled product is tested, the qualified product enters the automatic packaging part to realize automatic packaging. The turntable 7 of the automatic packaging part contains 4 groups of bag clamping mechanisms, and the opened bag is rotated and placed into the bottom of the collection box 6, when the PP transmission part 5 absorbs the specified amount, the turntable 7 rotates to the weighing device 18, and performs repeated detection of the weight. If the weight does not reach the specified amount, the PP transmission Part 5 will put the missing quantity of products on the feeder 17, the b...

Embodiment 3

[0078] The difference from Embodiment 1 is that in the turning part, the turning motor 21 drives the gripper 26 and the parts on it to rotate together to the horizontal state again, so as to realize the turning of the plastic part in the horizontal plane, and wait for the suction cup on the horizontal rotating part 10 to complete. At the same time, the color sensor 22 performs color judgment. The color sensor detects that there are plastic parts of different colors. The color sensor transmits the induction signal to the equipment control system, and the control motor stops. The material is removed, and the equipment is restarted to work normally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com