Uniform material distribution type conveyor

A uniform distribution and conveyor technology, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems that the sludge is difficult to distribute automatically and evenly, which affects the implementation efficiency and operation efficiency, and achieves simple structure, low construction investment cost, and mechanical Structurally Reliable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

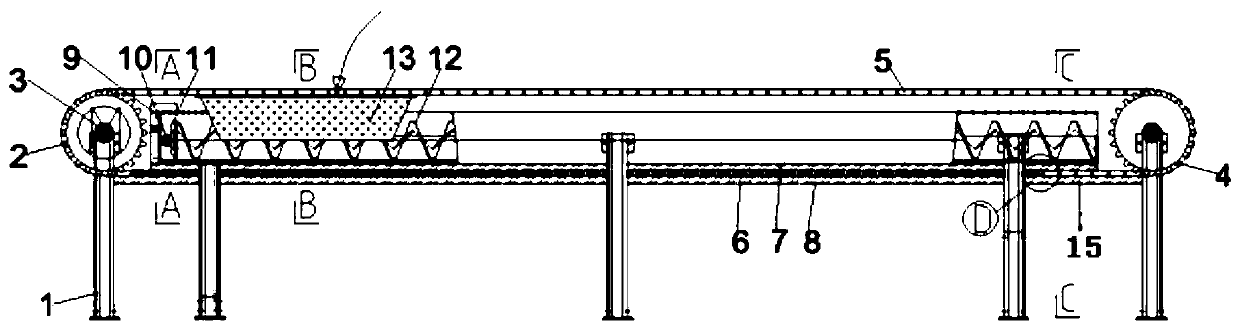

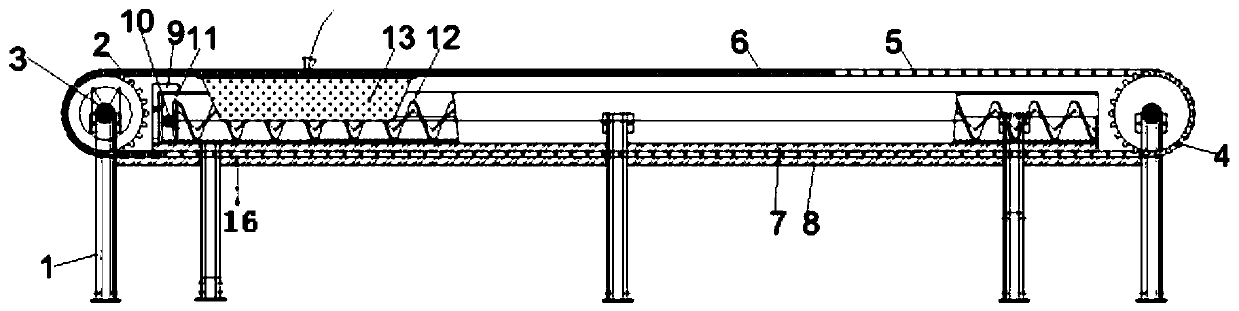

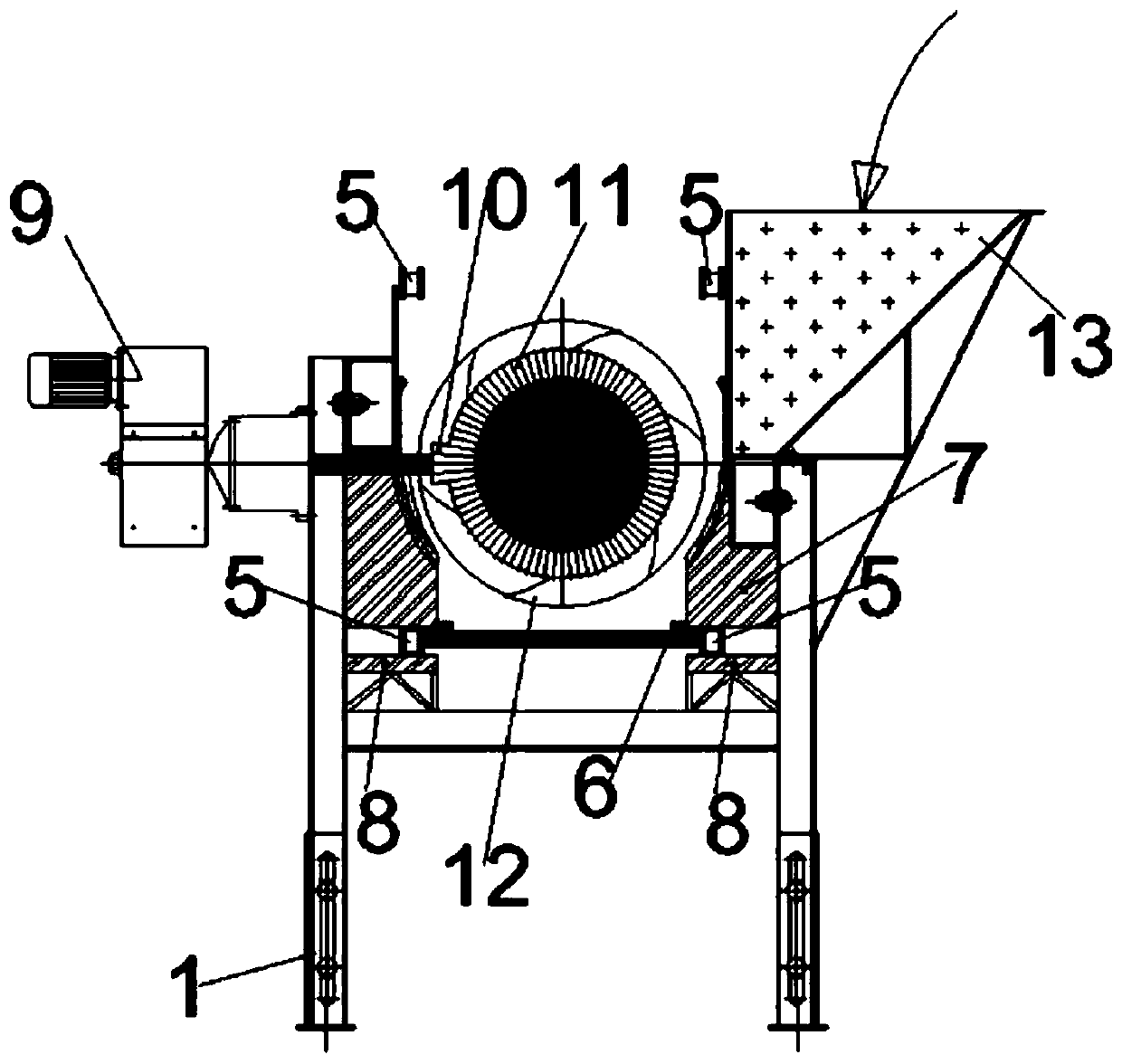

[0057] figure 1 A side view showing the discharge state at the far end of the uniform distributing screw conveyor according to this embodiment; figure 2 A side view showing the near-end discharge state of the uniform distribution screw conveyor according to the present embodiment; image 3 show figure 1 A-A sectional view in ; Figure 4 show figure 1 The B-B profile in ; Figure 5 show figure 1 C-C sectional view in ; Figure 6 show figure 1 Partial top view at D in .

[0058] Such as Figure 1 to Figure 6 As shown, the uniform distribution conveyor includes:

[0059] The bottomless feeding base tank 7 is installed on the frame 1, the inner wall of the feeding base tank 7 is arc-shaped, the rotating screw is located in the feeding base tank 7, and the rotating screw is provided with a helical blade 12, the outer contour of the helical blade 12 and the feeding The arc-shaped inner wall of the base groove 7 is compatible, and a driven bevel gear 11 is installed on one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com