Ultraviolet curing transparent color-repairing mother liquid as well as preparation method and application thereof

A technology of ultraviolet light and color correction, which is applied in coatings, radiation-absorbing coatings, epoxy resin coatings, etc., can solve problems such as adhesion problems, and achieve the effect of improving construction efficiency and combining firmly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

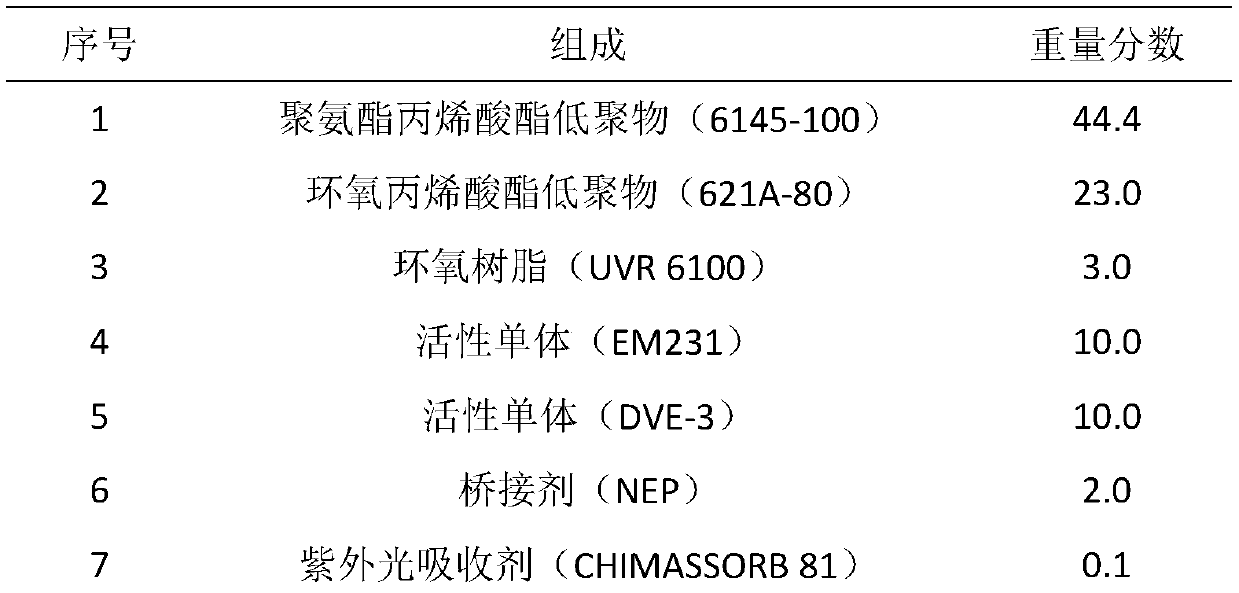

[0049] A UV-curing transparent color correction mother liquor formula is shown in Table 1a:

[0050] Table 1a UV curing transparent color correction masterbatch formula

[0051]

[0052]

[0053] Preparation method: in parts by weight, 44.4 parts of urethane acrylate oligomer, 23.0 parts of epoxy acrylate oligomer, 3.0 parts of epoxy resin, 20.0 parts of active monomer, 2.0 parts of bridging agent, 0.1 part of ultraviolet Light absorber, 3.5 parts of free radical photoinitiator, 2.5 parts of cationic photoinitiator, 0.2 part of defoamer, 0.5 part of leveling agent, 0.8 part of wetting agent, stirring at medium speed (700-1000 rpm / minutes) 20min to obtain UV-curable transparent color correction mother liquor X-1, the viscosity measured by Brookfield rotational viscometer at 25°C was 500cp.

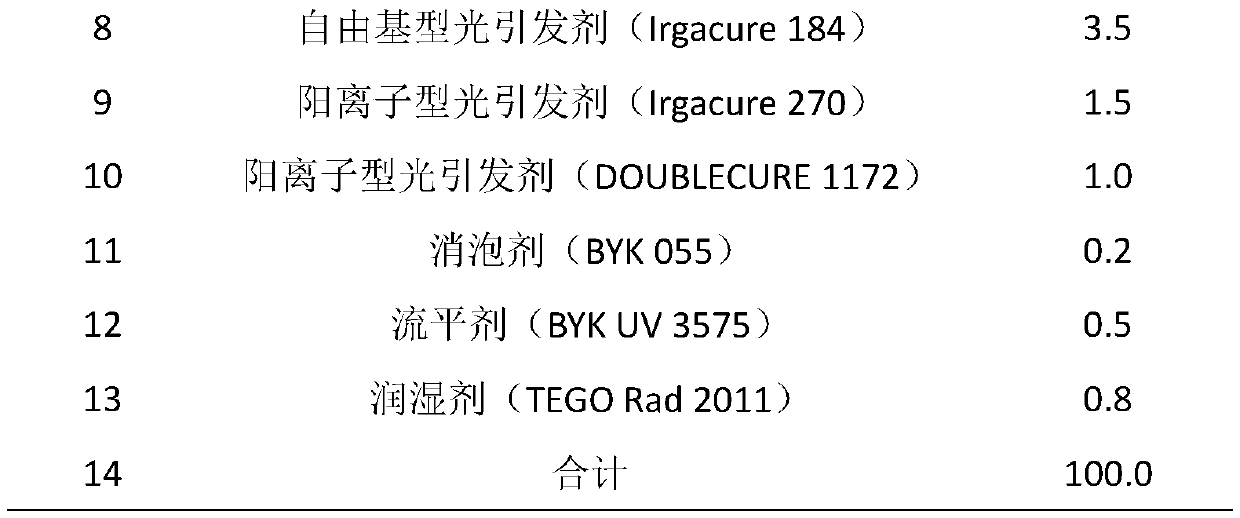

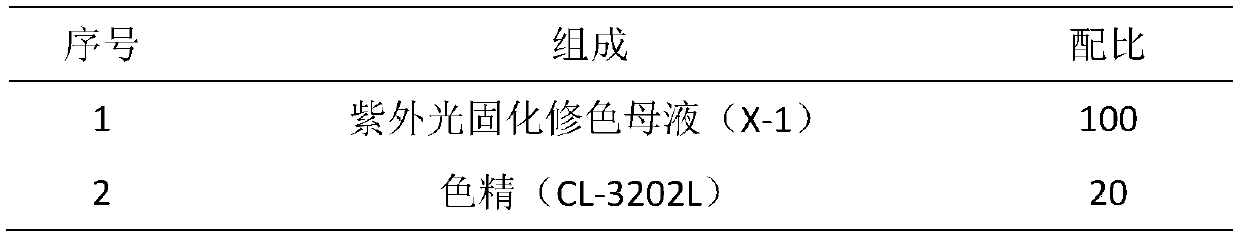

[0054] Table 1b The ratio of color correction mother liquor and color essence of UV color correction solution

[0055]

[0056] According to the color requirements, the color co...

Embodiment 2

[0066] The formula of UV curing transparent color correction mother liquor is shown in Table 2a:

[0067] Table 2a UV curing transparent color correction masterbatch formula

[0068]

[0069] Preparation method: by weight percentage, 51.0 parts of urethane acrylate oligomer, 10.2 parts of epoxy acrylate oligomer, 4.0 parts of epoxy resin, 15.0 parts of active monomer, 10.0 parts of bridging agent, 1.0 part of ultraviolet absorber agent, 4.0 parts of free radical photoinitiator, 3.0 parts of cationic photoinitiator, 0.2 part of defoamer, 0.6 part of leveling agent, 1.0 part of wetting agent, stirring at medium speed (700-1000 rpm) After 30 minutes, a UV-curable transparent color-correcting mother liquor (X-2) was prepared, and the viscosity measured by a Brookfield rotational viscometer at 25°C was 650 cp.

[0070] Table 2b The ratio of color correction mother liquor and color essence of UV color correction solution

[0071]

[0072] According to the color requirements,...

Embodiment 3

[0078] The formula of UV curing transparent color correction mother liquor is shown in Table 3a:

[0079] Table 3a UV curing transparent color correction masterbatch formula

[0080]

[0081]

[0082] Preparation method: by weight percentage, 36.59 parts of polyurethane acrylate oligomer, 28.5 parts of epoxy acrylate oligomer, 3.0 parts of epoxy resin, 19.0 parts of active monomer, 5.0 parts of bridging agent, 0.01 part of ultraviolet absorber agent, 4.0 parts of free radical photoinitiator, 1.5 parts of cationic photoinitiator, 0.1 part of defoamer, 0.8 part of leveling agent, 1.5 part of wetting agent, stirring at medium speed (700-1000 rpm) After 15 minutes, a UV-curable transparent color-correcting mother liquor (X-3) was prepared, and the viscosity measured by a Brookfield rotational viscometer at 25°C was 550 cp.

[0083] Table 3b The ratio of color correction mother liquor and color essence of UV color correction solution

[0084]

[0085] According to the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com