Rice wine and production technology thereof

A production process and rice wine technology, applied in the field of sweet wine, can solve the problems of unscientific production process, poor sanitation, unfavorable health, etc., and achieve the effects of wide drinking population, good hygiene and drinking safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of rice wine, formula comprises: glutinous rice, purified water, distiller's yeast, sugar and additive, and the parts by weight of each component are: 25 parts of glutinous rice, 30 parts of drinking water, 0.02 part of distiller's yeast, 5 parts of sugar and 2 parts by weight parts of additives.

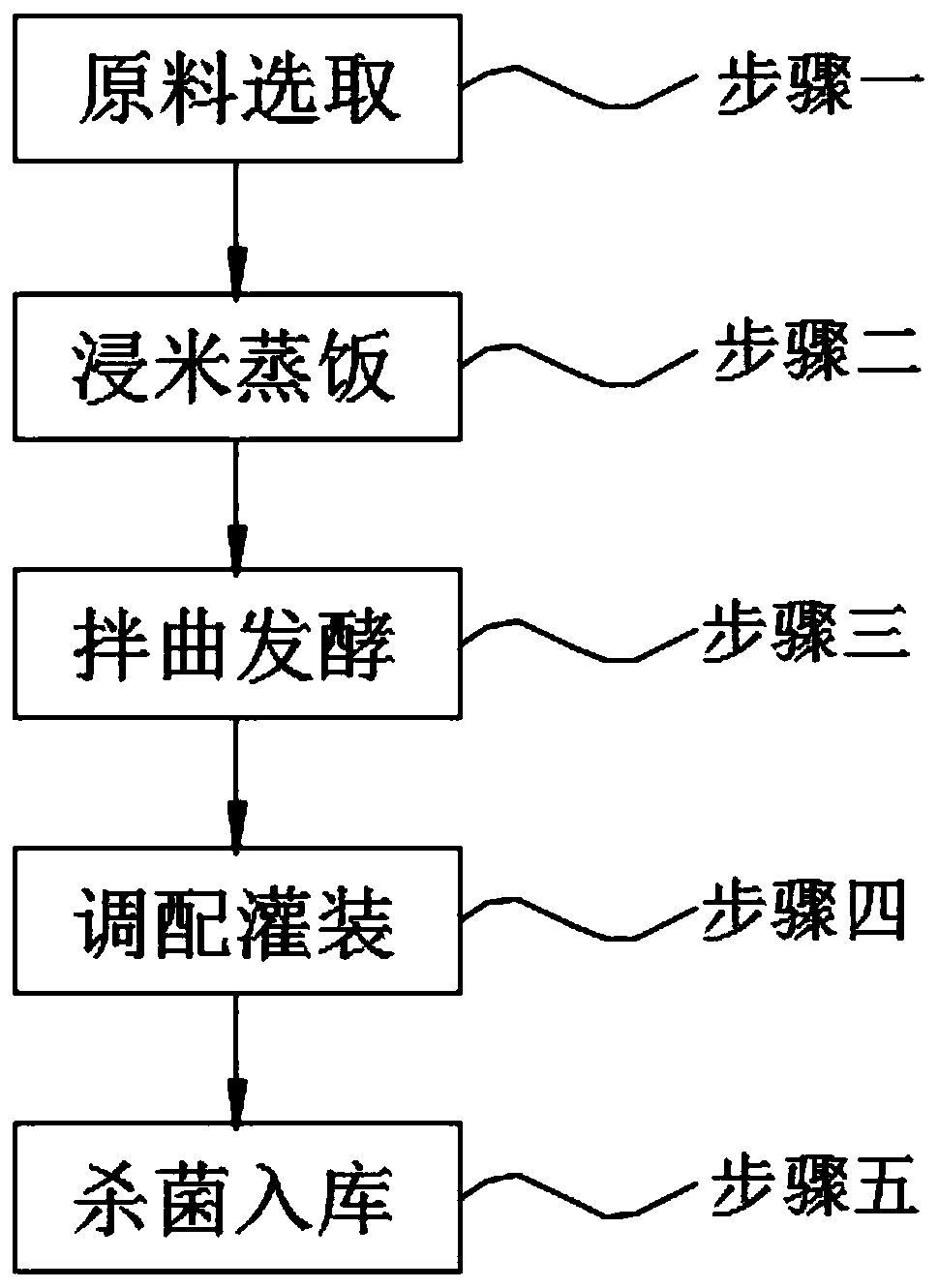

[0034] A production process of rice wine, comprising the following steps: Step 1, selecting raw materials; Step 2, soaking rice and steaming rice; Step 3, mixing koji and fermenting; Step 4, blending and filling; Step 5, sterilizing and storing;

[0035] Wherein in above-mentioned step 1, select according to the weight percent of each component respectively: 25 parts of glutinous rice, 30 parts of drinking water, 0.02 part of distiller's yeast, 5 parts of sugar and 2 parts of additives;

[0036] Wherein in above-mentioned step 2, soaking rice and steaming rice comprises the following steps:

[0037] 1) Soak the glutinous rice in pure water for 12-13 hours at room temp...

Embodiment 2

[0053] A kind of rice wine, formula comprises: glutinous rice, purified water, distiller's yeast, sugar and additive, and the parts by weight of each component are: 25 parts of glutinous rice, 30 parts of drinking water, 0.02 part of distiller's yeast, 6 parts of sugar and 2 parts by weight parts of additives.

[0054] A production process of rice wine, comprising the following steps: Step 1, selecting raw materials; Step 2, soaking rice and steaming rice; Step 3, mixing koji and fermenting; Step 4, blending and filling; Step 5, sterilizing and storing;

[0055] Wherein in above-mentioned step 1, select according to the weight percent of each component respectively: 25 parts of glutinous rice, 30 parts of drinking water, 0.02 part of distiller's yeast, 6 parts of sugar and 2 parts of additives;

[0056] Wherein in above-mentioned step 2, soaking rice and steaming rice comprises the following steps:

[0057] 1) Soak the glutinous rice in pure water for 12-13 hours at room temp...

Embodiment 3

[0073] A kind of rice wine, formula comprises: glutinous rice, purified water, distiller's yeast, sugar and additive, and the parts by weight of each component are: 25 parts of glutinous rice, 30 parts of drinking water, 0.02 part of distiller's yeast, 7 parts of sugar and 2 parts by weight parts of additives.

[0074] A production process of rice wine, comprising the following steps: Step 1, selecting raw materials; Step 2, soaking rice and steaming rice; Step 3, mixing koji and fermenting; Step 4, blending and filling; Step 5, sterilizing and storing;

[0075] Wherein in above-mentioned step 1, select according to the weight percent of each component respectively: 25 parts of glutinous rice, 30 parts of drinking water, 0.02 part of distiller's yeast, 7 parts of sugar and 2 parts of additives;

[0076] Wherein in above-mentioned step 2, soaking rice and steaming rice comprises the following steps:

[0077] 1) Soak the glutinous rice in pure water for 12-13 hours at room temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com