Synthetic method for LiXSe2 polycrystalline compound and LiXSe2 single crystal

A synthesis method and compound technology, applied in selenium/tellurium compounds, chemical instruments and methods, metal selenide/telluride, etc., can solve problems such as insufficient reaction, insufficient melting of raw materials, insufficient contact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

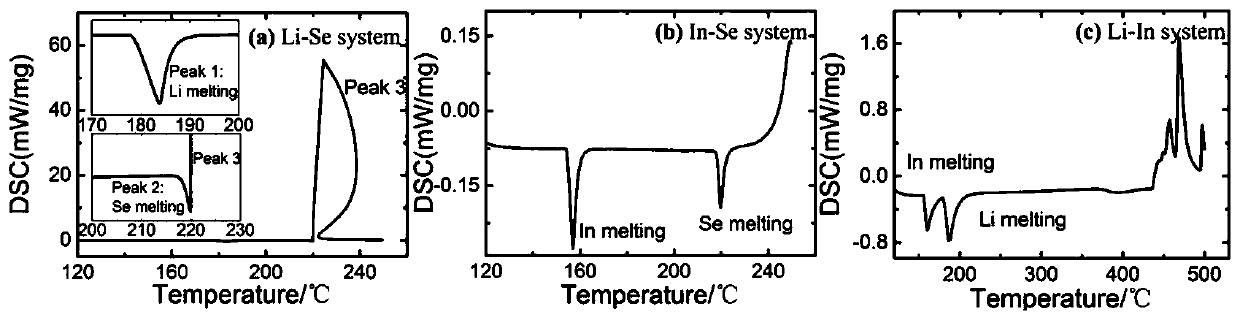

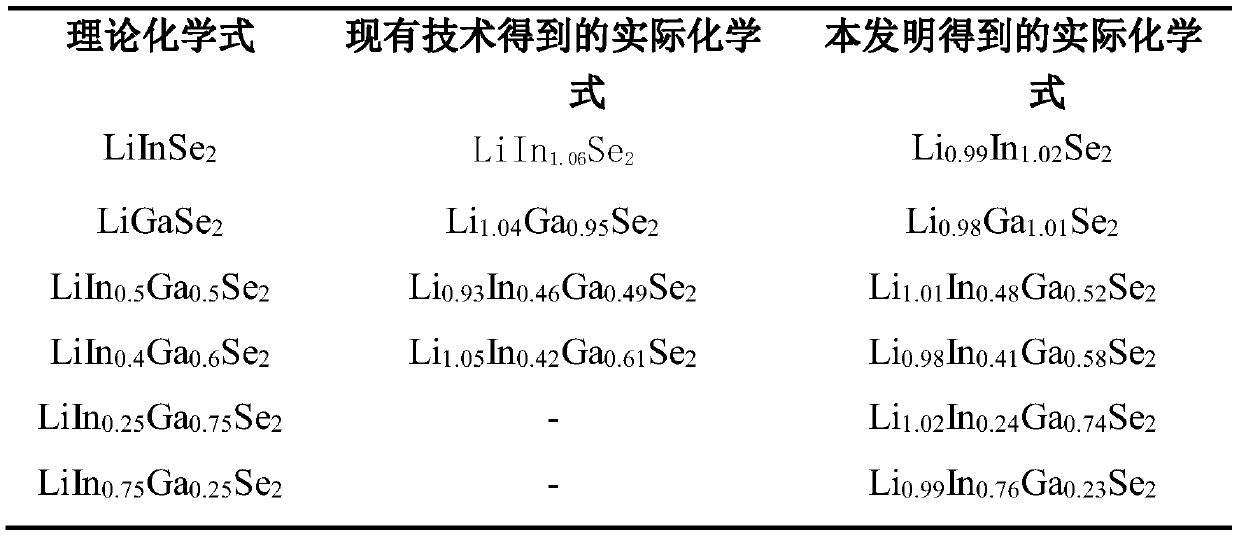

Embodiment 1

[0044] First, soak the inner graphite crucible and the outer quartz crucible with acetone to remove organic impurities, soak them in aqua regia to remove inorganic impurities, then clean them with deionized water, dry them, and put them on the inner wall of the dried quartz crucible Deposit a carbon film. According to the molar ratio of 1:1:2, Li, In and Se are accurately weighed, and an additional 3% of Li and 2% of Se are added, and put into the inner graphite crucible together. After the graphite crucible is covered with a stopper, put it into a carbon-coated quartz crucible, and vacuumize to 5×10 -5 Pa, the quartz crucible was sealed with an oxyhydrogen flame and placed in a rocking furnace. Raise the temperature of the mixing furnace to 180°C at a rate of 30°C / h. At this temperature, Li and Se start to react, reducing the corrosion of the quartz crucible by Li at high temperature and the volatilization of Se. Then the temperature was raised to 230° C. at a rate of 10° C...

Embodiment 2

[0046] First, soak the inner PBN crucible and the outer quartz crucible with acetone to remove organic impurities, soak them in aqua regia to remove inorganic impurities, then clean them with deionized water, dry them, and put them on the inner wall of the dried quartz crucible Deposit a carbon film. According to the molar ratio of 1:1:2, the three elements of Li, Ga and Se are accurately weighed, and an additional 2% of Li and 2% of Se are added, and put into the inner PBN crucible together. Put the PBN crucible into the carbon-coated quartz crucible, and evacuate to 5×10 -5 Pa, the quartz crucible was sealed with an oxyhydrogen flame and placed in a rocking furnace. Raise the temperature of the mixing furnace to 180°C at a rate of 40°C / h. At this temperature, Ga is completely melted, and Li and Se begin to react, which reduces Li's corrosion of the quartz crucible and the volatilization of Se at high temperatures. Then the temperature was raised to 220°C at a rate of 5°C / h...

Embodiment 3

[0048] First, soak the inner graphite crucible and the outer quartz crucible with acetone to remove organic impurities, soak them in aqua regia to remove inorganic impurities, then clean them with deionized water, dry them, and put them on the inner wall of the dried quartz crucible Deposit a carbon film. According to the molar ratio of 1:0.5:0.5:2, Li, In, Ga and Se three elements are accurately weighed, and an additional 3% Li and 3% Se are added, and put into the inner graphite crucible together. After the graphite crucible is covered with a stopper, put it into a carbon-coated quartz crucible, and vacuumize to 5×10 -5 Pa, the quartz crucible was sealed with an oxyhydrogen flame and placed in a rocking furnace. Raise the temperature of the mixing furnace to 180°C at a rate of 30°C / h. At this temperature, Ga is completely melted, and Li and Se start to react, reducing the corrosion of Li on the quartz crucible and the volatilization of Se at high temperatures. Then the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com