Fabricated concrete box culvert structure and construction method thereof

A construction method and concrete technology, which is applied in the direction of basic structure engineering, underwater structures, artificial islands, etc., can solve the problems of heavy weight and difficult hoisting, and achieve the effect of reducing the difficulty of hoisting and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

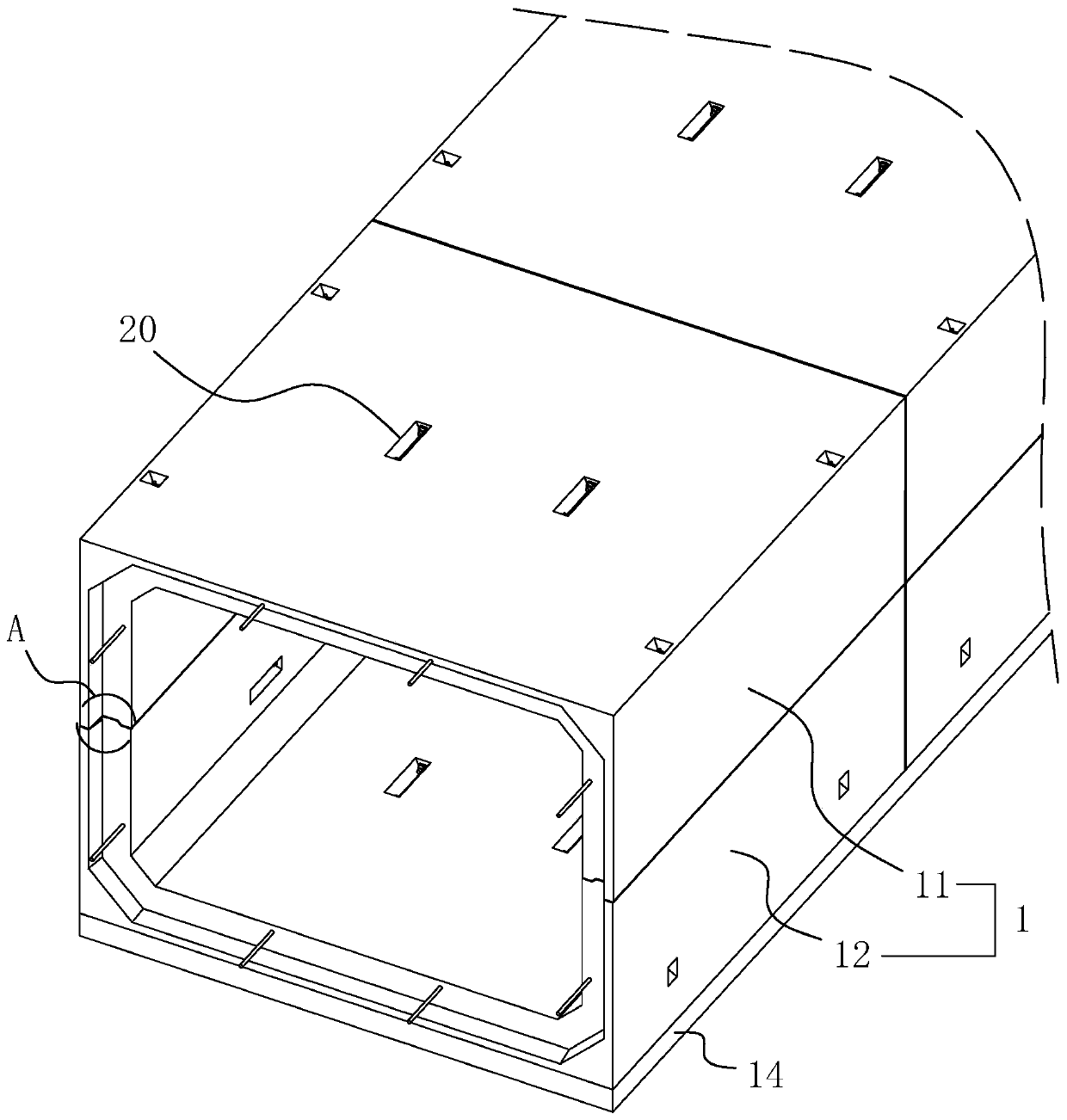

[0047] A prefabricated concrete box culvert structure, refer to figure 1 , which includes several box culvert segments 1 connected in sequence, each of which includes a symmetrically arranged upper segment 11 and a lower segment 12, and the upper segment 11 is located above the lower segment 12. A base plate 14 arranged horizontally is arranged below the several lower segments 12 .

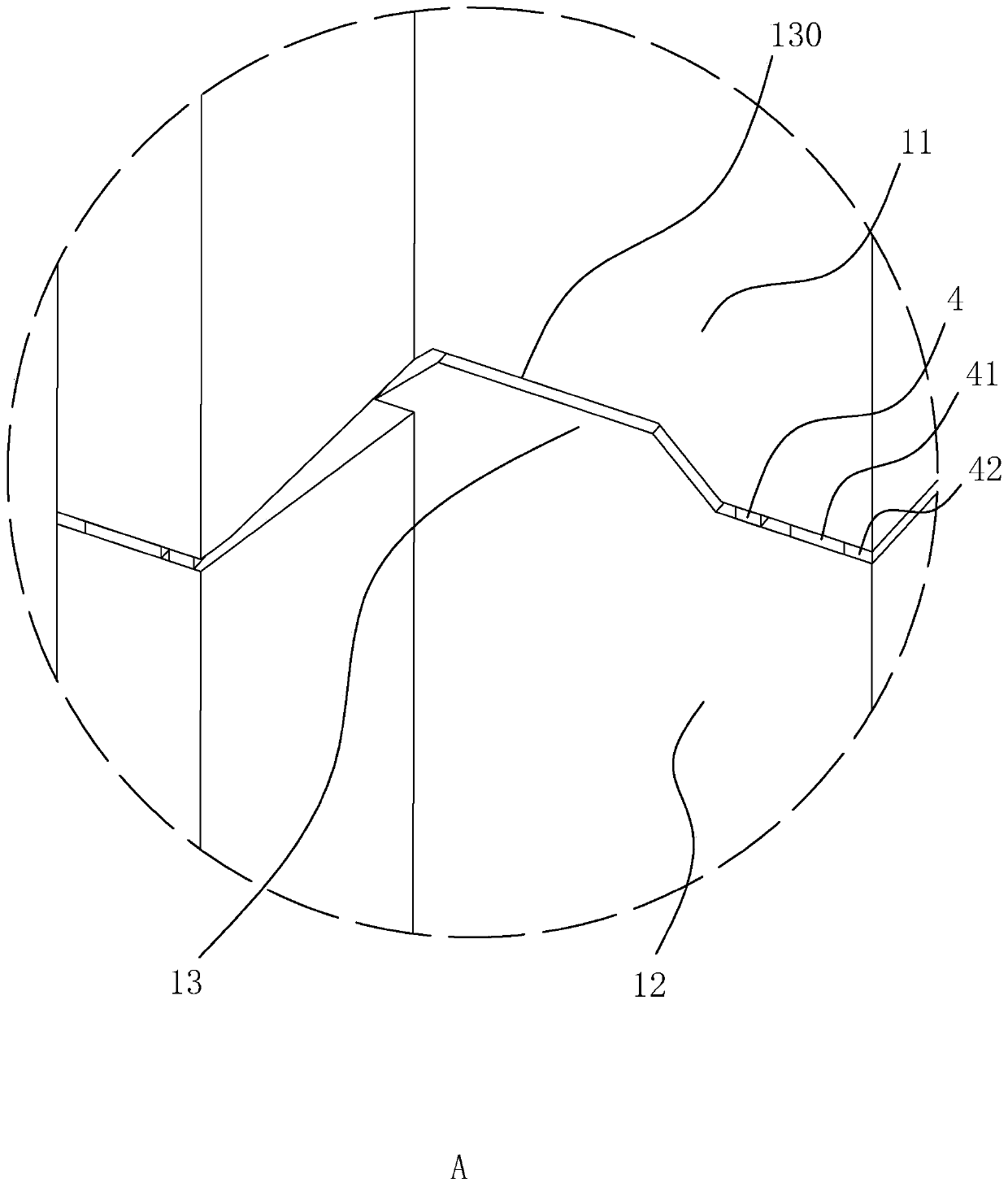

[0048] refer to figure 2 , the top wall at both ends of the lower section 12 is integrally formed with inserting blocks 13 , and the bottom wall at both ends of the upper section 11 is provided with slots 130 for the inserting blocks 13 to fit and insert.

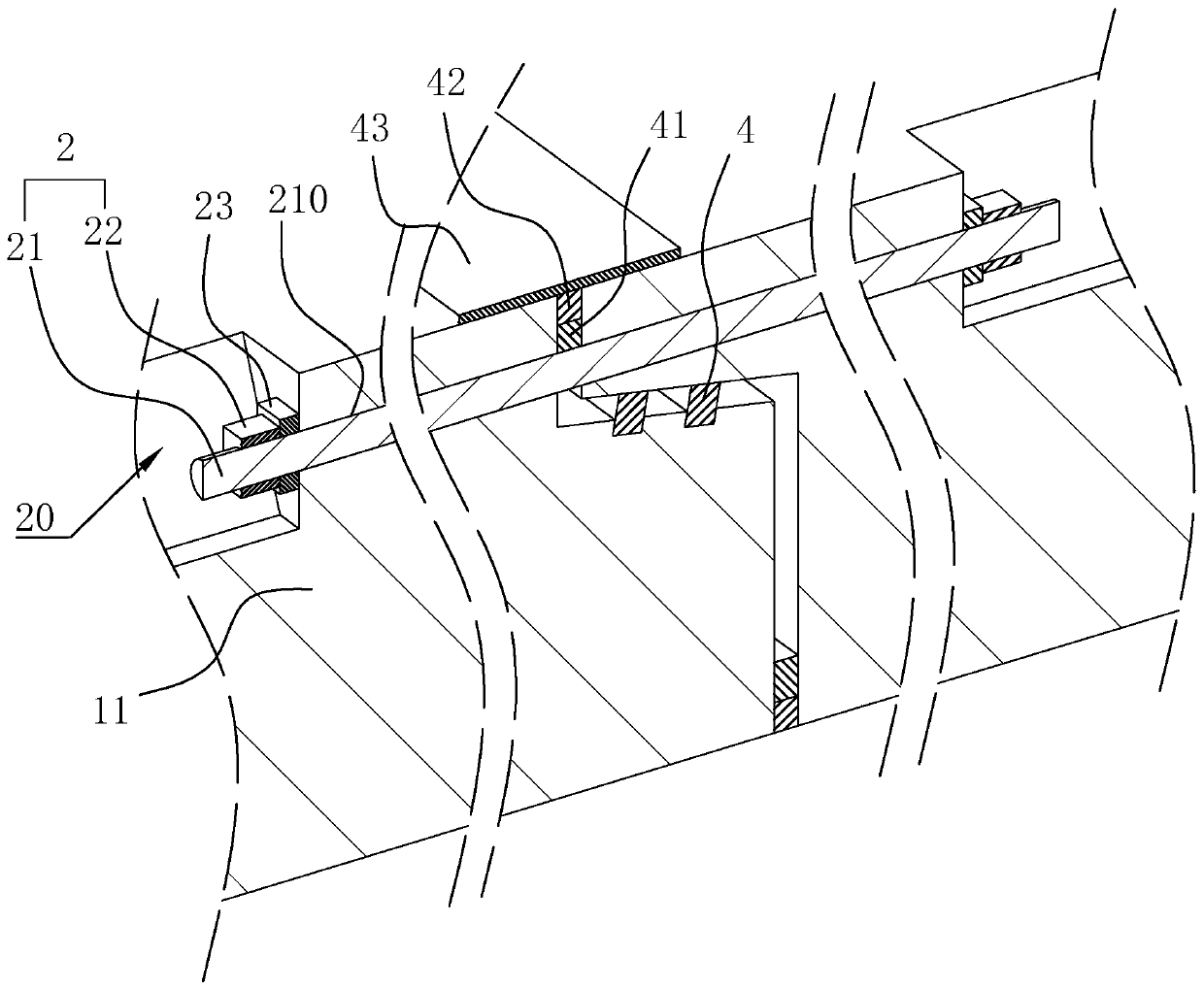

[0049] refer to image 3 , between adjacent upper segments 11 , between adjacent lower segments 12 , and between opposite upper segments 11 and lower segments 12 are all connected by connecting components 2 . The connection assembly 2 includes a twisted wire 21 and a pair of anchors 22. Several pairs of Anchor holes 20, a preset hole 210 i...

Embodiment 2

[0052] A method for constructing a prefabricated concrete box culvert, comprising the following steps:

[0053] S1. Construction preparation: refer to Figure 4 , according to the design drawings to measure and set out, sprinkle out the excavation sidelines of the foundation pit 3 with lime, to accurately determine the plane position of the culvert.

[0054] S2. Box culvert foundation excavation: refer to Figure 4 Before foundation pit 3 is excavated, cut-off ditch 31 is set around the top opening of foundation pit 3 to prevent ground water from flowing into foundation pit 3. Widen 50cm around the excavation sideline of foundation pit 3 as the construction work space, use manual excavation with excavator, and use manual bottom cleaning when the excavation is about 10cm away from the design elevation. After the foundation pit 3 is excavated to the related elevation, a drainage ditch 32 and a water well 33 are provided around the bottom of the foundation pit 3 to drain away t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com