Adsorbate gas adsorption phase density model construction and absolute adsorption capacity calculation method

A technology of gas adsorption and construction method, which is applied in the field of exploration to achieve the effect of high accuracy and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Such as Figure 7 A method for constructing an adsorbate gas adsorption phase density calculation model is shown, comprising the following steps:

[0033] S10. Obtain the gas phase density ρ of the adsorbate gas at different pressures at the temperature T1 g , and the gas phase density ρ g Regression into a polynomial function related to pressure p;

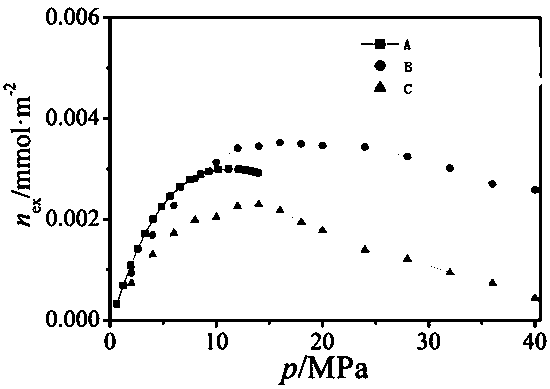

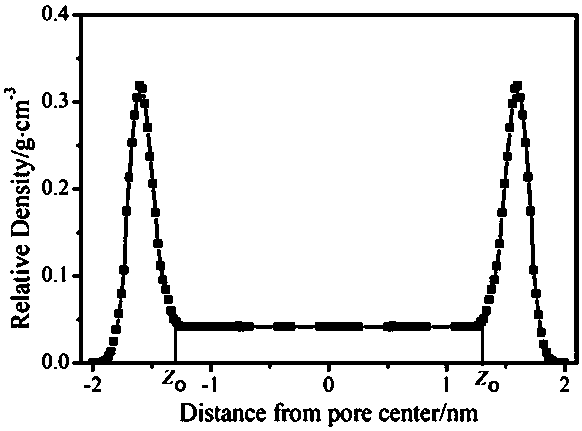

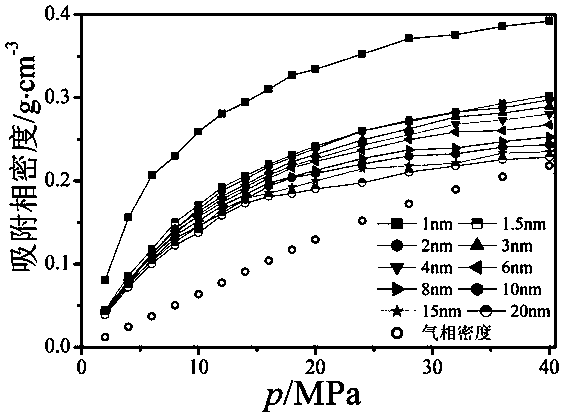

[0034] S20. Construct the slit pore structure model of the adsorbent and the slit pore diameters constructed are various, and obtain the excess adsorption capacity and adsorption phase of the adsorbate gas in the adsorption system at different temperatures, different pressures, and different pore diameter points by means of molecular simulation volume;

[0035] S30. Calculate the absolute adsorption amount according to the excess adsorption amount and the volume of the adsorption phase obtained in step S20;

[0036] S40, calculating the adsorption phase density of the adsorbate gas in the adsorption system under differ...

Embodiment 2

[0041] Based on the principle of embodiment 1, this embodiment discloses a specific implementation method, which specifically includes the following steps:

[0042] S10. Obtain the gas phase density of the adsorbate gas at different pressures at a certain temperature from the NIST database, and calculate the gas phase density ρ g Returning to a polynomial function related to the pressure p, it can be seen from the formula (1), the adsorbate gas can be such as methane, carbon dioxide, hydrogen and other gases.

[0043] ρ g =a 0 +a 1 p+a 2 p 2 +a 3 p 3 (1)

[0044] S20. According to the crystal structure model of the adsorbent, use the Materials studio 6.0 software to construct the supercell structure of the adsorbent, thereby constructing the slit pore structure of the adsorbent. The diameters of the constructed slit holes include 1nm, 1.5nm, 2nm, and 3nm , 4nm, 6nm, 8nm, 10nm, 15nm, 20nm, etc. Based on this, the adsorption process of adsorbate gas molecules in the na...

Embodiment 3

[0057] In this embodiment, the adsorbent is kaolinite mineral, and the adsorption medium is methane gas as an example to illustrate the model construction method of this scheme.

[0058] S10. Using the methods in Examples 1 and 2 to obtain the coefficients of the gas phase density fitting polynomial of methane at different temperatures are shown in Table 1, where R is the fitting coefficient.

[0059] Table 1 Values of coefficients of methane density regression formula

[0060]

[0061] S20. According to the crystal structure model of the adsorbent, use Material studio6.0 software to construct the supercell structure of the adsorbent, thereby constructing the slit pore structure of the adsorbent. The diameters of the constructed slit holes include 1nm, 1.5nm, 2nm, 3nm, 4nm, 6nm, 8nm, 10nm, 15nm, 20nm, etc. Based on this, the adsorption process of adsorbate gas molecules in the nanoscale pores of the adsorbent at different temperatures was constructed.

[0062] Based on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com