Semiconductor device and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of semiconductor device performance, device substrate thickness uniformity, and effective area thickness uniformity. Achieve the effect of improving thickness uniformity and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

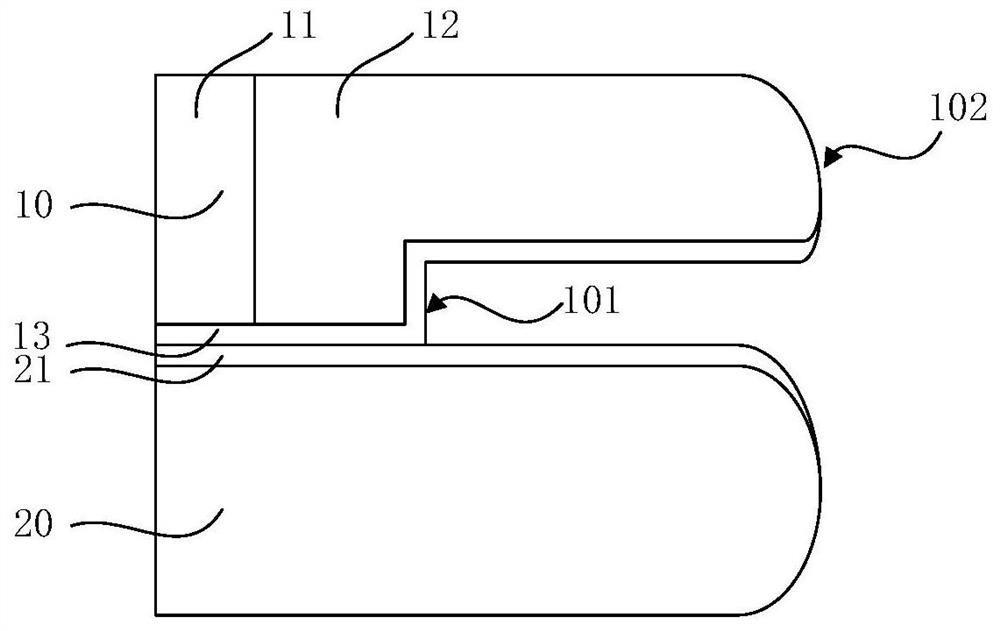

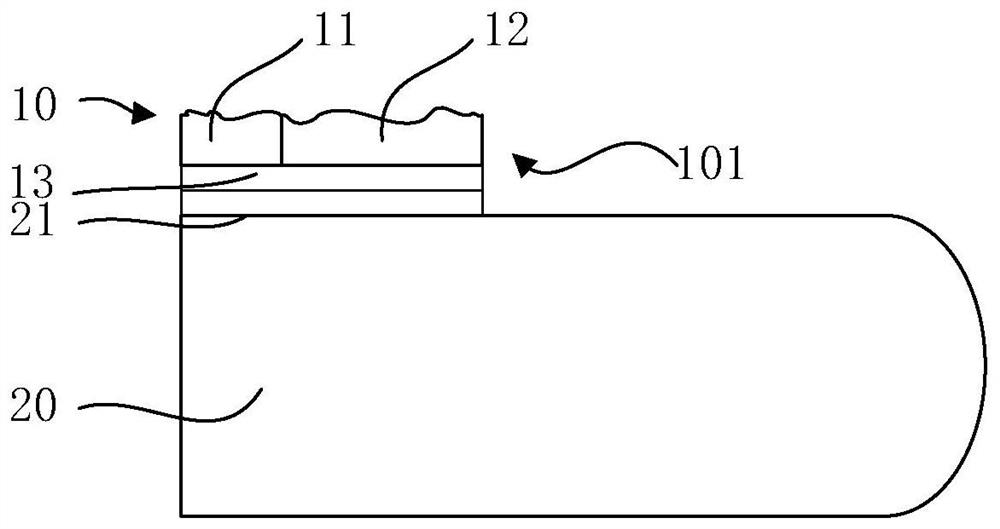

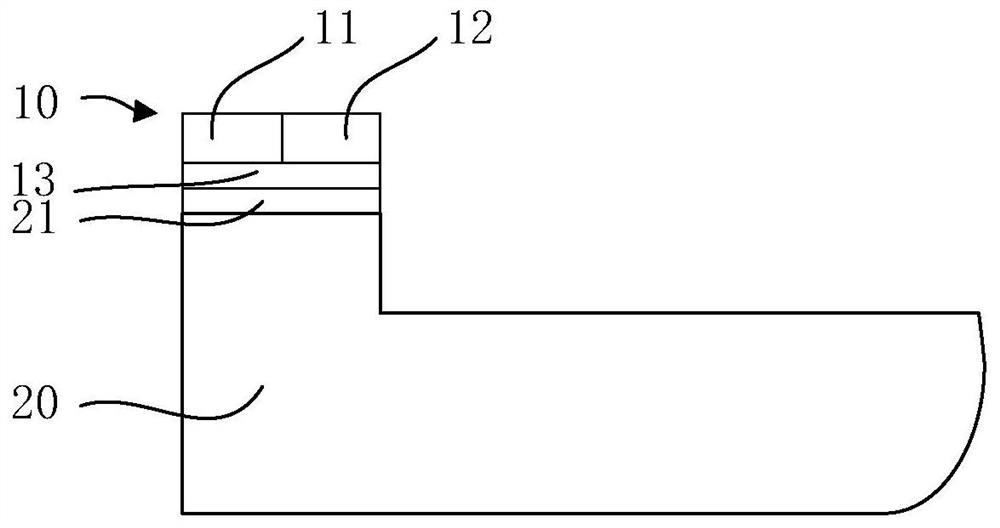

[0027] Figure 1~4 It is a structural schematic diagram of each step of a manufacturing method of a semiconductor device. Please refer to Figure 1 to Figure 4 As shown, the manufacturing method of the semiconductor device is specifically as follows.

[0028] First, please refer to figure 1 As shown, a bonded wafer is provided, and the bonded wafer includes a device wafer 10 positioned above and a carrier wafer 20 positioned below. A first insulating layer 13 and a second insulating layer 21 are also formed at the bonding interface between the device wafer 10 and the carrier wafer 20 .

[0029] The device wafer 10 includes an active area 11 and an inactive area 12 surrounding the active area 11 . The invalid area 12 includes a first edge 101 and a second edge 102, the first edge 101 surrounds the active area 11 and forms a bonding surface with the carrier wafer 20, and the second edge 102 surrounds the first The edge 101 does not form a bonding surface with the carrier wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com