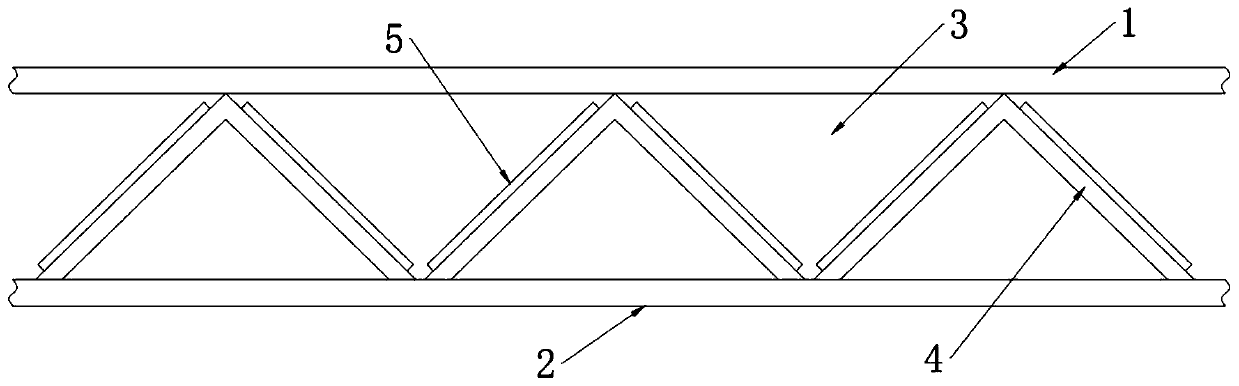

Solar assembly packaging structure

A technology of solar modules and encapsulation structures, applied in electrical components, semiconductor devices, photovoltaic power generation, etc., can solve the problems of unavoidable mechanical loads on cells, limited reliability of components, and limited use range, etc. , flexible component installation angle, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

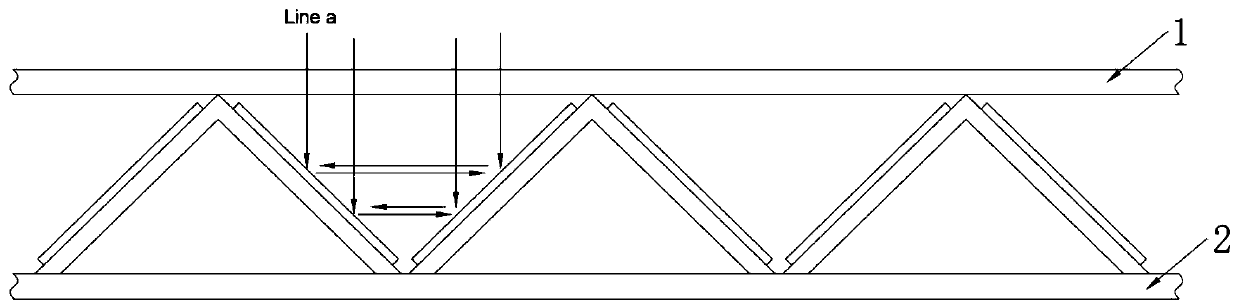

[0022] Example one, as attached to the instructions figure 2 As shown, the incident light Line a is perpendicular to the glass layer 1 on the light-receiving surface. The incident light will be reflected and reused in this design structure. The cell 5 and the upper glass layer 1 of the light-receiving surface form a certain angle, so that the incident light The back battery sheet 5 and the triangular support 4 can be reused after reflection, and the packaging density of the components is improved. In addition, the triangular support 4 can carry all the mechanical loads, and the battery itself is not affected by any external force.

Embodiment 2

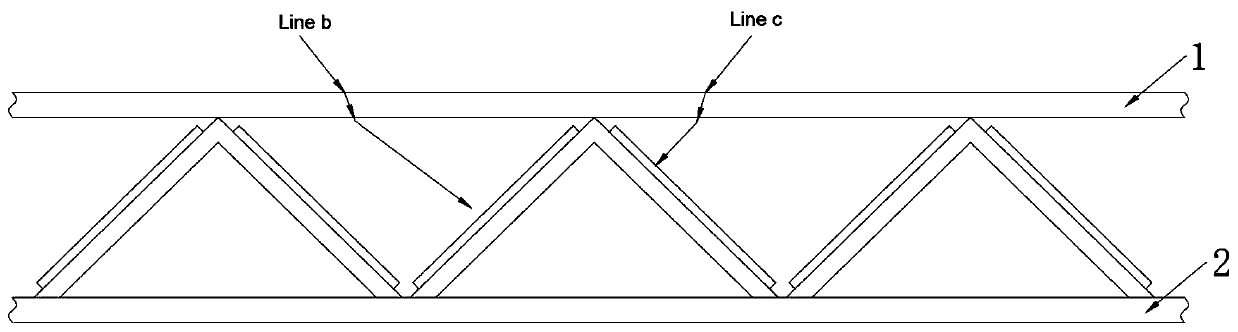

[0023] Embodiment two, as attached image 3 As shown, the incident light Line b and Line c are directed to the glass layer 1 on the light-receiving surface obliquely from both sides. Under light of different incident angles (except for vertical incident light), the components all have the main light-receiving surface cell 5 and The secondary light-receiving surface cell 5, and the two are complementary, the total output voltage and current of the module will not have large fluctuations.

[0024] As a preference, the angle between the hypotenuse of the triangular bracket 4 and the upper glass layer 1 or the lower glass layer 2 is set to be 5°-45°, which allows a wide choice of installation angles for the components, a wide range of trials, and easy adjustment of the solar cell 5 and the light receiving. The installation tilt angle of the glass layer 1 on the surface.

[0025] As a preference, the width of the cell 5 is set to 20-50 mm. In the present invention, the cell 5 is a small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com