Zinc-based metal organic framework material, preparation method of iron-nitrogen co-doped carbon-based oxygen reduction electrocatalyst and application

An organic framework and electrocatalyst technology, applied in circuits, electrical components, battery electrodes, etc., can solve the problems of less attention to use, and achieve the effects of simple and easy preparation method, wide source of raw materials, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Preparation of zinc-based metal-organic framework (Zn-TTPA):

[0041] The ligand TTPA-4 (13.4mg, 0.03mmol), terephthalic acid (10.0mg, 0.06mmol), zinc nitrate hexahydrate (17.8mg, 0.06mmol) were dissolved in 10mL of DMF and deionized water (V:V =1:1) in a mixed solvent, placed in a hydrothermal tank of tetrafluoroethylene and stirred evenly, heated to 100°C for 50 hours, slowly lowered to 15°C, collected the crystals formed, and used solvent for the crystals (N,N-di Methylformamide, water, ethanol) were washed successively, and dried at room temperature to obtain a zinc-based metal-organic framework material. The yield is about 65%.

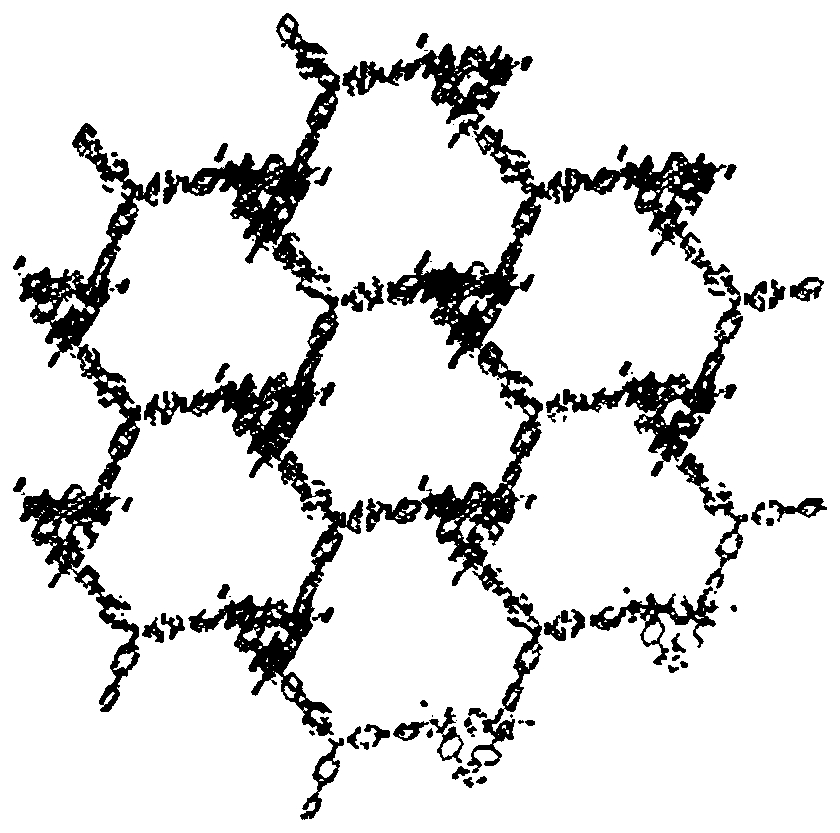

[0042] figure 1 It is the structural diagram of the Zn-TTPA zinc-based metal organic framework material obtained in Example 1 of the present invention viewed along the c-axis direction. In Zn-TTPA, viewed along the c-axis direction, a quasi-hexagonal frame is formed on the Zn-TTPA frame shaped channel, the window size is approx.

[0...

Embodiment 2

[0046] Step 1, the preparation of precursor Fe-Zn-TTPA:

[0047] Ligand TTPA-4 (13.4mg, 0.03mmol), terephthalic acid (10.0mg, 0.06mmol), zinc nitrate hexahydrate (17.8mg, 0.06mmol), iron nitrate nonahydrate (1.01mg, 0.0025mmol) were added 10mL of DMF and deionized water (V:V=1:1) mixed solvent, heated to 100°C under stirring, stirred for 72 hours, slowly lowered to 15°C, filtered to obtain a powdery solid, the yield was about 67% .

[0048] Step 2. Preparation of iron-nitrogen co-doped carbon material

[0049] Put the powdery solid precursor Fe-Zn-TTPA material into a tube furnace, raise the temperature to 950°C at 5°C / min in a nitrogen atmosphere, keep at this temperature for 2h, and cool to room temperature at 5°C per minute, An iron-nitrogen co-doped carbon-based electrocatalyst for oxygen reduction was obtained.

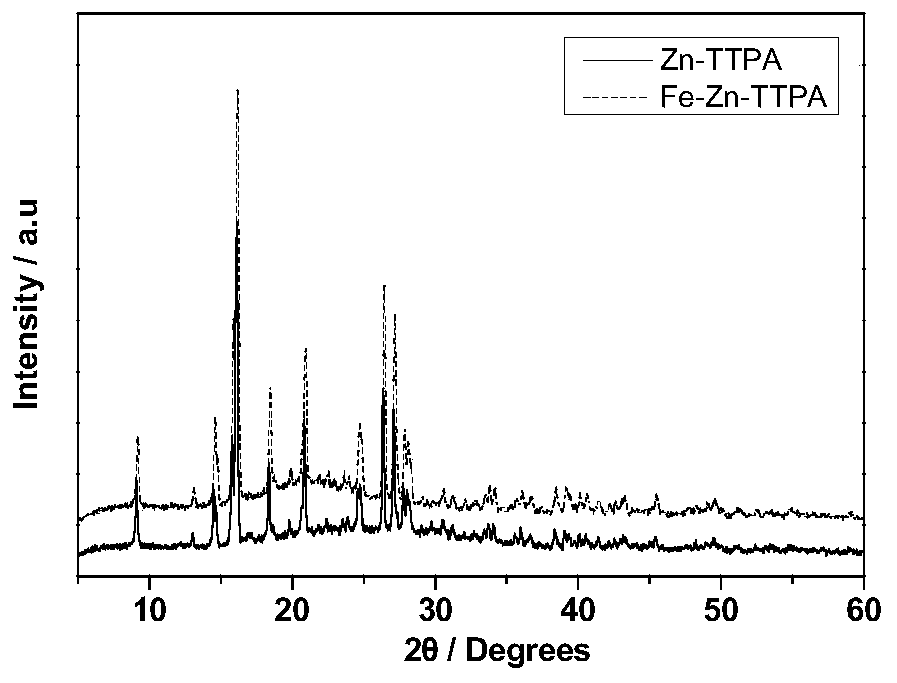

[0050] image 3 It is the XRD spectrogram of the obtained zinc-based metal organic framework material Zn-TTPA and the precursor Fe-Zn-TTPA before carbonizati...

Embodiment 3

[0059] Step 1, the preparation of precursor Fe-Zn-TTPA:

[0060] Ligand TTPA-4 (17.9mg, 0.04mmol), terephthalic acid (11.7mg, 0.07mmol), zinc nitrate hexahydrate (20.8mg, 0.07mmol), iron nitrate nonahydrate (1.21mg, 0.003mmol) were added 20mL of DMF and deionized water (V:V=1:1) mixed solvent, heated to 95°C under stirring, stirred for 45 hours, slowly lowered to 30°C, filtered to obtain a powdery solid, the yield was about 64% .

[0061] Step 2. Preparation of iron-nitrogen co-doped carbon material

[0062] Put the powdery solid precursor Fe-Zn-TTPA material into a tube furnace, in an argon atmosphere, raise the temperature to 1100°C at 10°C / min, keep at this temperature for 2h, and cool to room temperature at 10°C per minute , to obtain iron-nitrogen co-doped carbon-based oxygen reduction electrocatalysts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com