Battery pack component and vehicle

A battery pack and component technology, applied in the automotive field, can solve the problems of high space size requirements for battery packs, increased energy density of battery packs, and increased difficulty in maintenance operations, achieving less action, reduced installation time, and improved service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

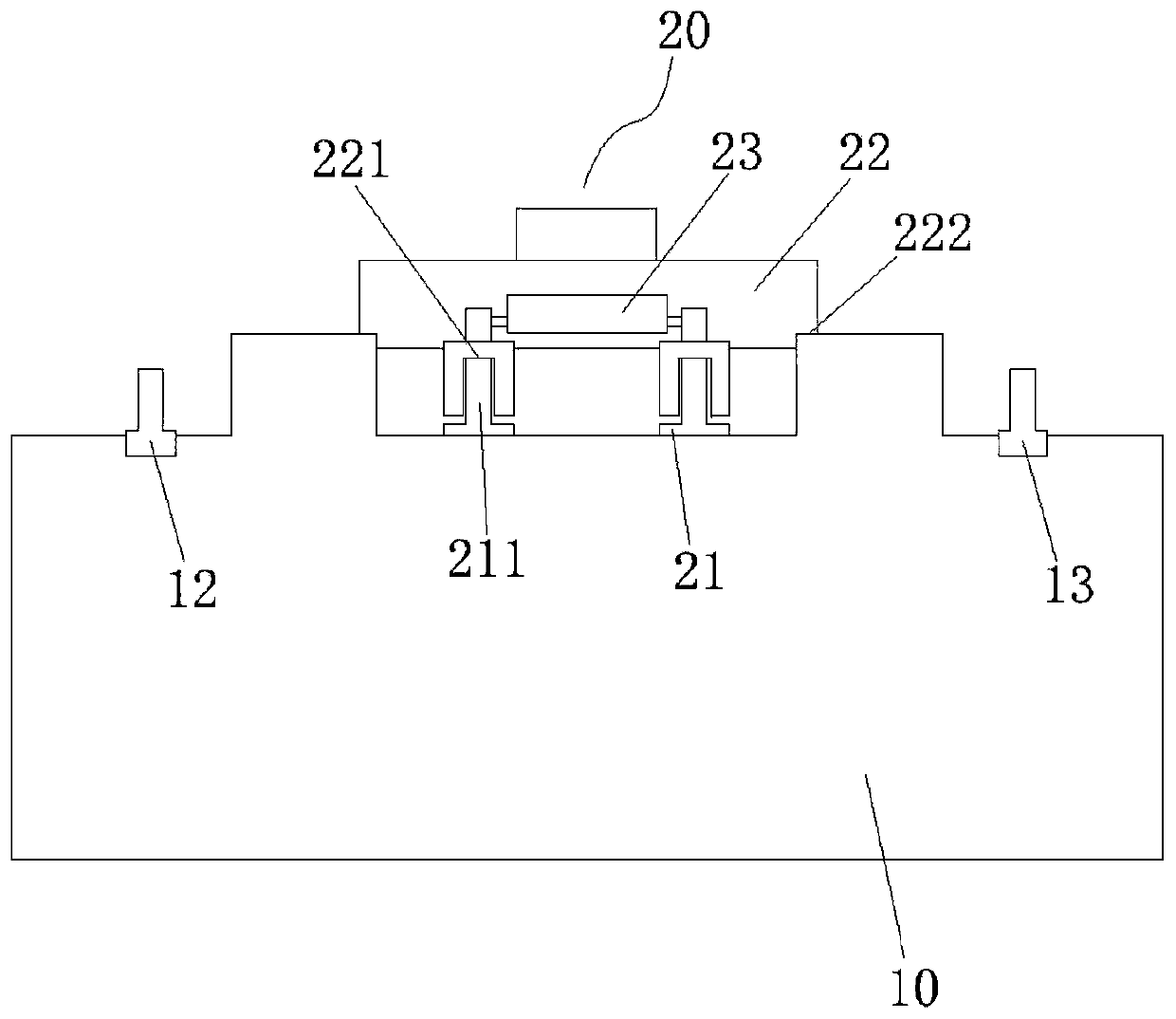

[0028] combine figure 1 , this embodiment provides a battery pack assembly, including a battery pack, a power distribution module 10, and a manual maintenance switch 20, the manual maintenance switch 20 is used to control the on-off of the high-voltage circuit inside the power distribution module 10, and the distribution The electric module 10 is arranged on the battery pack, the power distribution module 10 is provided with an installation groove 11, and the manual maintenance module 20 includes a socket 21 and a plug 22, and the socket 22 is arranged at the bottom of the installation groove 11. The socket 22 is electrically connected to the power distribution module 10, and the plug 22 is plugged into the socket 21 to set the manual maintenance switch 20 at least partially in the installation groove 11; provided in this embodiment A battery pack assembly integrates the manual maintenance switch 20 on the power distribution module 10, and the battery pack only needs to reserv...

Embodiment 2

[0037] Embodiment 2 is the preferred embodiment of embodiment 1

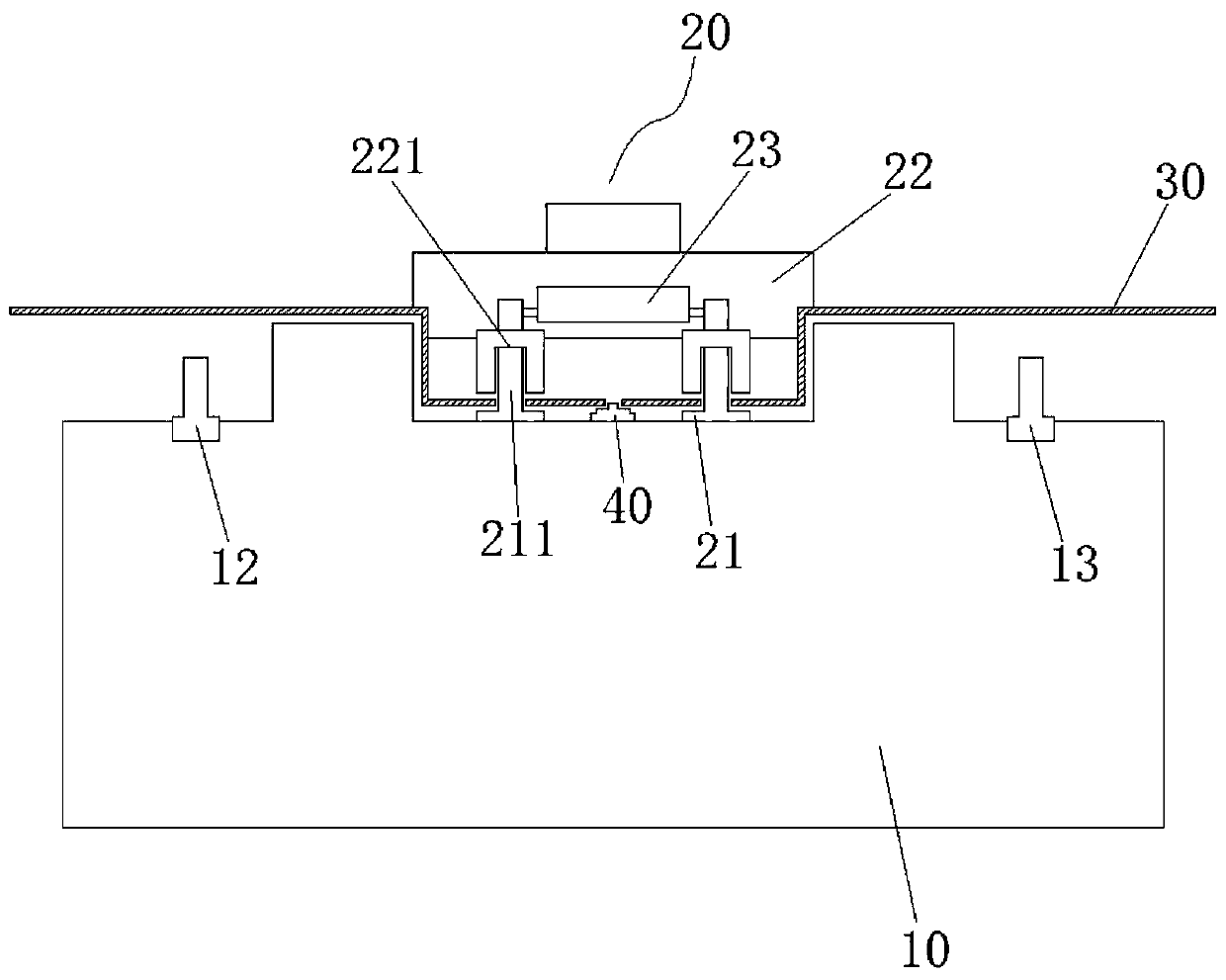

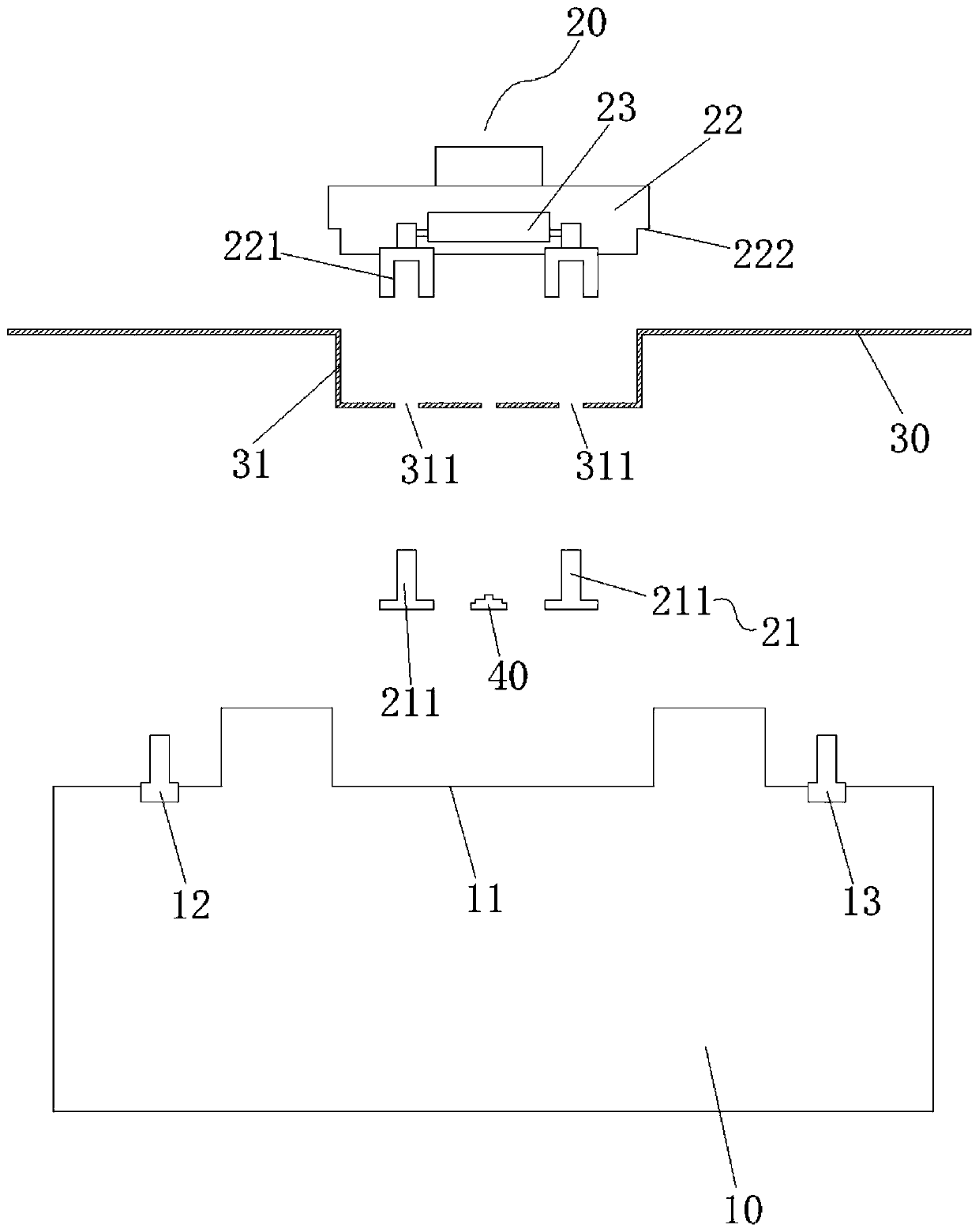

[0038] combine figure 2 and image 3, the present embodiment provides a battery pack assembly, which also includes a battery pack case 30 (Fig. 2 and image 3 Among them, the shell 30 is only a part located at the battery pack assembly), the battery pack shell 30 is provided with a relief structure 31 that matches the installation groove 11, and the relief structure 31 is arranged on the between the power distribution module 10 and the manual maintenance switch 20; specifically, the relief structure is arranged between the power distribution module 10 and the plug 22.

[0039] Further, the relief structure 31 is provided with an opening 311, and the opening 311 can accommodate the insertion pin 211 to perforate. A battery pack assembly described in this embodiment makes it possible to open the battery pack shell 30 only when the plug 22 is pulled out, and it is impossible to touch the live parts inside the b...

Embodiment 3

[0046] This embodiment provides an automobile, including the battery pack assembly described in the above technical solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com