Furosemide tablets and preparation method thereof

A furosemide tablet and a technology for furosemide are applied in the directions of pharmaceutical formulations, medical preparations without active ingredients, and medical preparations containing active ingredients, etc., and can solve the cumbersome method of furosemide tablets and the drug resistance of human body. , increasing production costs and other issues, to avoid drug resistance, reduce production costs, and simplify complex effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A furosemide tablet, the furosemide tablet is made up of the following raw materials in parts by weight:

[0030] 25 parts of furosemide, 16.75 parts of corn starch, 55 parts of lactose, 27 parts of purified water, 1 part of sodium carboxymethyl starch and 1 part of magnesium stearate.

[0031] A kind of furosemide sheet, concrete preparation method step is as follows:

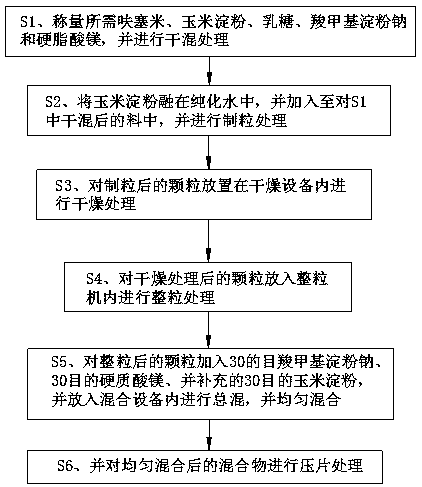

[0032] S1. Weigh the required furosemide, cornstarch, lactose, sodium carboxymethyl starch and magnesium stearate, and carry out dry mixing treatment;

[0033] S2. Melting cornstarch in purified water, adding it to the dry-blended material in S1, and performing granulation;

[0034] S3, placing the granulated particles in a drying device for drying treatment;

[0035] S4, put the dried particles into the granulator for granulation processing;

[0036] S5. Add 30 mesh sodium carboxymethyl starch, 30 mesh magnesium stearate, and supplemented 30 mesh cornstarch to the sized granules, put them into the m...

Embodiment 2

[0044] A furosemide tablet, the furosemide tablet is made up of the following raw materials in parts by weight:

[0045] 25 parts of furosemide, 18 parts of corn starch, 55 parts of lactose, 29 parts of purified water, 1.5 parts of sodium carboxymethyl starch and 1.1 parts of magnesium stearate.

[0046] A kind of furosemide sheet, concrete preparation method step is as follows:

[0047] S1. Weigh the required furosemide, cornstarch, lactose, sodium carboxymethyl starch and magnesium stearate, and carry out dry mixing treatment;

[0048] S2. Melting cornstarch in purified water, adding it to the dry-blended material in S1, and performing granulation;

[0049] S3, placing the granulated particles in a drying device for drying treatment;

[0050] S4, put the dried particles into the granulator for granulation processing;

[0051] S5. Add 30 mesh sodium carboxymethyl starch, 30 mesh magnesium stearate, and supplemented 30 mesh cornstarch to the sized granules, put them into th...

Embodiment 3

[0059] A furosemide tablet, the furosemide tablet is made up of the following raw materials in parts by weight:

[0060] Furosemide 23-25 parts, corn starch 17-19 parts, lactose 55-59 parts, purified water 27-30 parts, carboxymethyl starch sodium 0.4-2 parts and magnesium stearate 0.5-1.3 parts.

[0061] A kind of furosemide sheet, concrete preparation method step is as follows:

[0062] S1. Weigh the required furosemide, cornstarch, lactose, sodium carboxymethyl starch and magnesium stearate, and carry out dry mixing treatment;

[0063] S2. Melting cornstarch in purified water, adding it to the dry-blended material in S1, and performing granulation;

[0064] S3, placing the granulated particles in a drying device for drying treatment;

[0065] S4, put the dried particles into the granulator for granulation processing;

[0066] S5. Add 30 mesh sodium carboxymethyl starch, 30 mesh magnesium stearate, and supplemented 30 mesh cornstarch to the sized granules, put them into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com