Pure reverse flow shell pipe type fresh water cooler

A shell-and-tube cooler technology, applied in the direction of tubular elements, heat exchanger types, heat exchanger shells, etc., can solve the problems of heat exchanger consumables, low cooling efficiency, high manufacturing cost, etc., to achieve enhanced heat transfer, Improved heat transfer efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

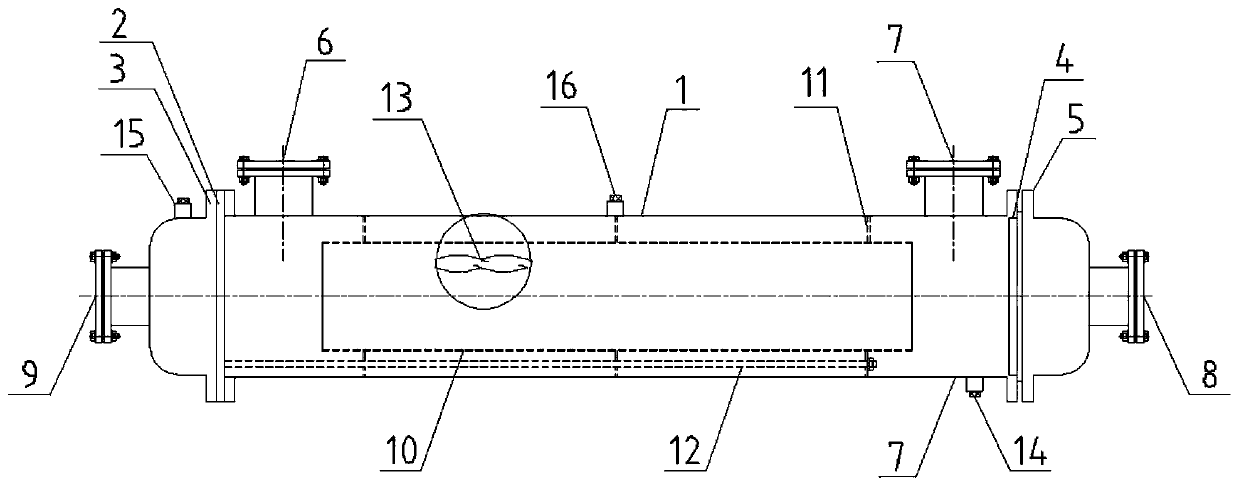

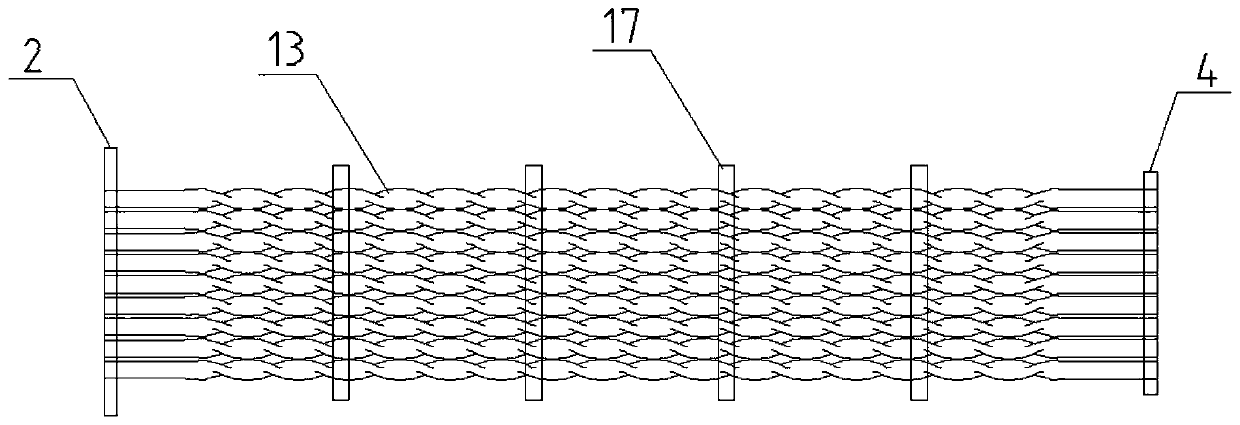

[0024] like figure 1 As shown, a pure counter-flow shell-and-tube type fresh water cooler includes a first tube box 3, a shell 1 and a second tube box 5, and the first tube box 3 and the second tube box 5 are respectively connected to two parts of the shell 1. There is a cooling core inside the shell 1, and tube sheets are arranged at both ends of the cooling core. The first tube box 3 is provided with a tube-side cooling water outlet 9, the second tube box 5 is provided with a tube-side cooling water inlet 8, and the side of the shell 1 is provided with shell-side fresh water The inlet 6 and the shell side fresh water outlet 7, the shell side fresh water outlet 7 is arranged at a position close to the tube side cooling water inlet 8, and the shell side fresh water inlet 6 is arranged at a position close to the tube side cooling water outlet 9, so that the cooling water and the The flow direction of fresh water is opposite, forming the effect of countercurrent heat exchange a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com