Natural gas engine test system for exhaust gas-fuel catalytic reforming and catalyst regeneration, and control method

A catalytic reforming and test system technology, which is applied in the field of natural gas engine test system and control, can solve the problems of difficult dismantling and replacement, high price and high cost of reforming catalyst, and achieve the effect of avoiding catalyst deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

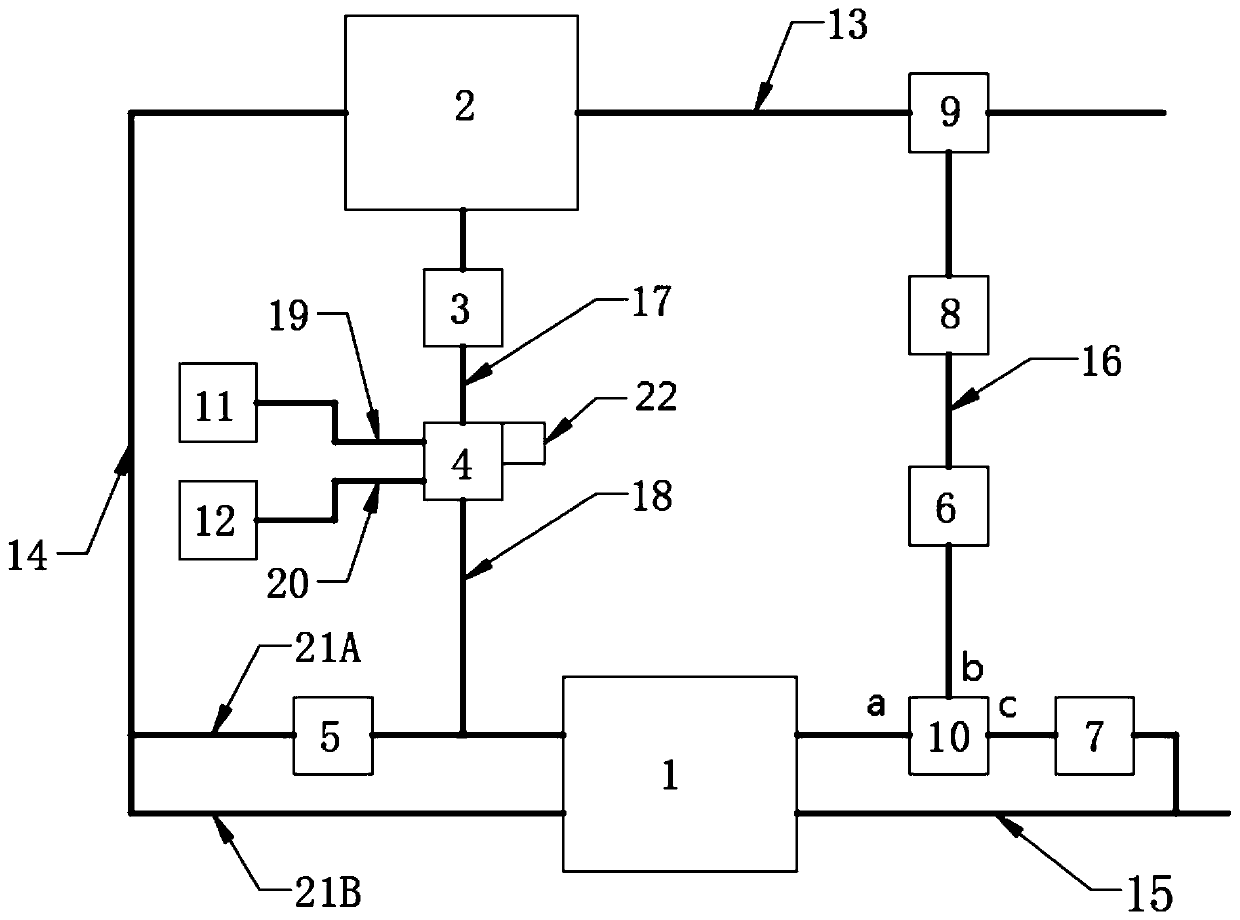

[0021] Such as figure 1 The shown exhaust gas-fuel catalytic reforming and catalyst regeneration natural gas engine test system includes reformer 1, engine 2, mixer 9, intercooler 8, tee pipe 10, gas tank 3, flow regulating valve 4, and controller 22. H 2 Tank 11 and N 2 Tank 12; wherein, the reaction gas inlet 1A of the reformer 1 is connected to the engine exhaust pipe 14 through the first exhaust branch pipe 21A, and the first exhaust branch pipe 21A is provided with a REGR front-end valve 5, and the exhaust gas of the reformer 1 The inlet 1B is connected to the engine exhaust pipe 14 through the second exhaust branch pipe 21B, the engine exhaust pipe 14 is connected to the exhaust port of the engine, and the reformer gas outlet 1C of the reformer 1 is connected to the inlet a of the tee pipe 10 , the outlet b of the tee pipe 10 is connected in series with the intercooler 8 and the mixer 9 in sequence through the reformed gas bypass pipe 16 (the reformed gas bypass pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com