Hot-melt pressure sensitive adhesive composition having improved rheological properties

An adhesive and composition technology, applied in the field of bonding substrates and hot-melt pressure-sensitive adhesives, can solve the loss of structural integrity of adhesives, reduction of adhesive bonding toughness, and adhesive bonding. Failure and other problems, to achieve the effect of high bond strength, good high temperature heat resistance, low odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

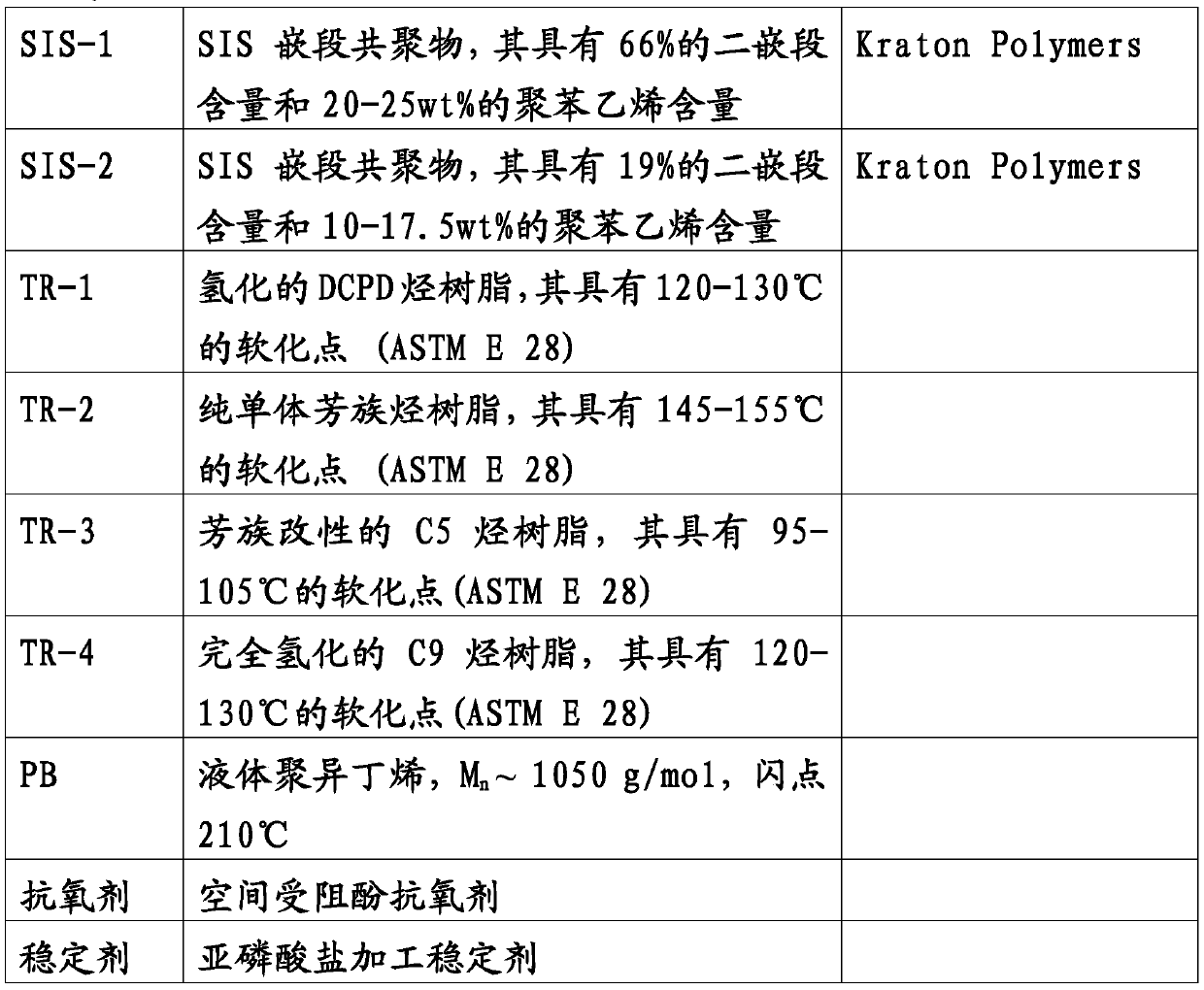

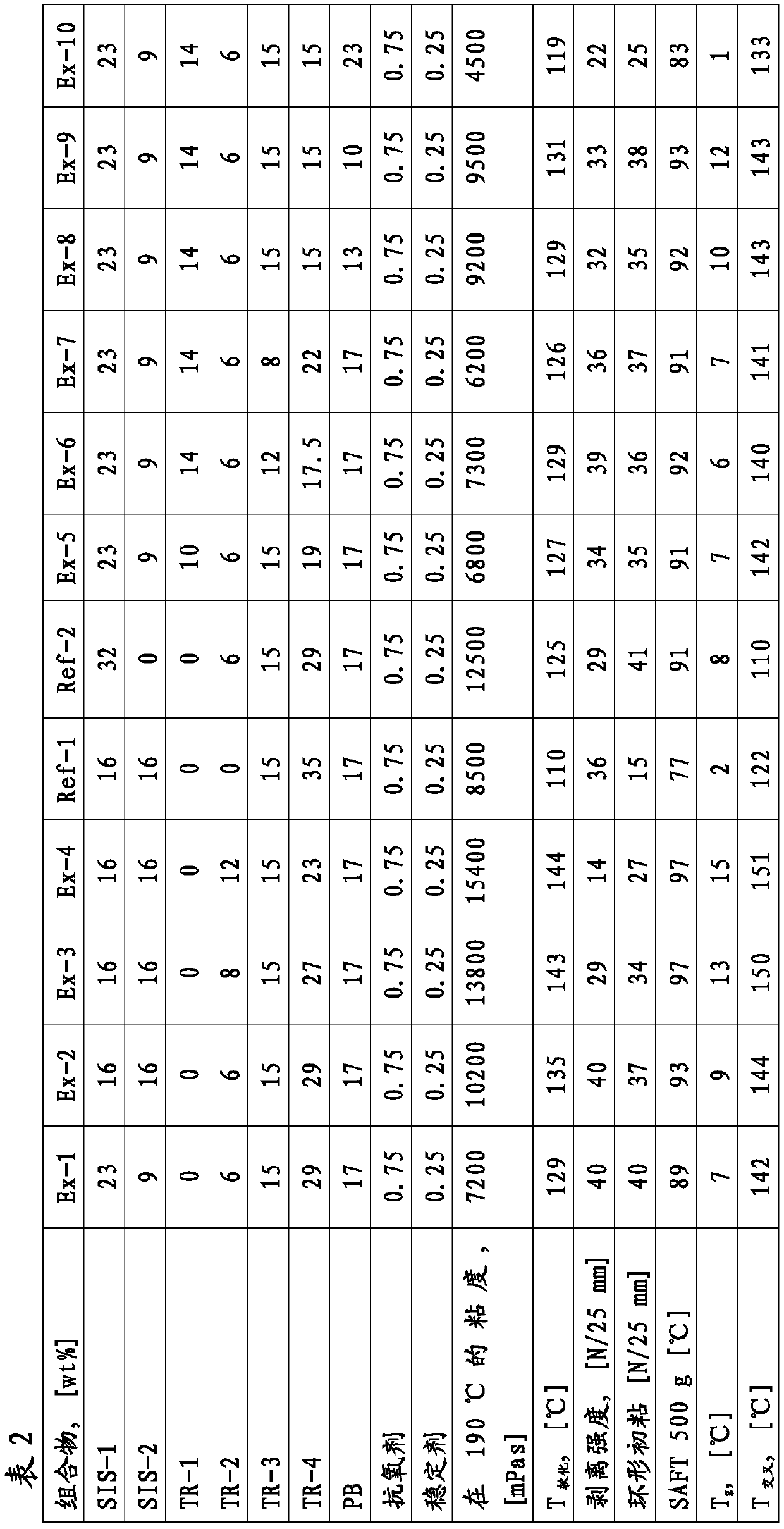

[0084] The compounds and products shown below in Table 1 were used in the examples.

[0085] Table 1

[0086]

[0087] Preparation of Adhesive Composition

[0088] For each adhesive composition, the ingredients shown in Table 1 were mixed in a Sigma kneader at a temperature of 180°C. The preparation process begins by mixing the styrenic block copolymer, a small portion of the resin and additives. The first mixing step was in CO 2 - Under atmosphere and for 45 minutes, then add the rest of the resin and continue mixing under vacuum for 30 minutes.

[0089] The liquid polyisobutylene was then added to the mixture and mixing was continued for an additional 30 minutes under vacuum. The adhesive compositions were stored in siliconized boxes for one day before being used to characterize their properties.

[0090] Viscosity at 190°C

[0091] Viscosity was measured using a Brookfield DV-2 Thermosel viscometer with a No. 27 spindle at a temperature of 190°C at 10 revolution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com