Welding method, device and system for printed board assembly with fine-pitch connector

A welding method and connector technology, applied in auxiliary devices, welding equipment, printed circuits, etc., can solve problems such as virtual welding and continuous welding, and achieve the effect of improving welding quality and improving welding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

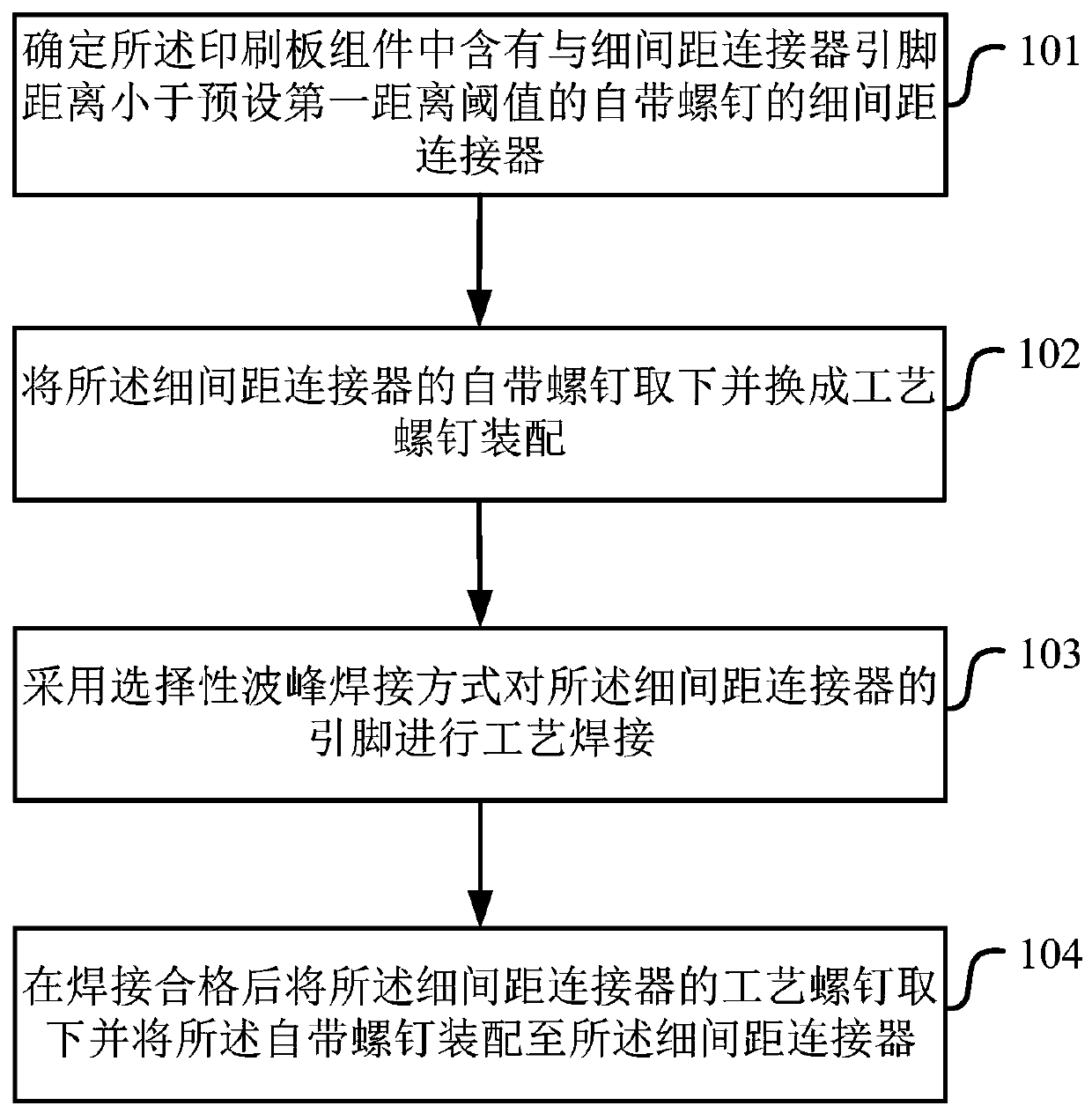

[0034] figure 1 A schematic flow chart showing the implementation of the soldering method for a printed board assembly including fine-pitch connectors in Embodiment 1 of the present application is shown.

[0035] As shown in the figure, the soldering method of the printed board assembly containing fine-pitch connectors includes:

[0036] Step 101, determining that the printed board assembly contains a fine-pitch connector with screws whose distance from the pin of the fine-pitch connector is less than a preset first distance threshold;

[0037] Step 102, removing the self-contained screws of the fine-pitch connector and replacing them with process screws for assembly;

[0038] Step 103, performing process welding on the pins of the fine-pitch connector by means of selective wave soldering;

[0039] Step 104 , after the welding is qualified, remove the process screws of the fine-pitch connector and assemble the self-contained screws to the fine-pitch connector.

[0040] Prin...

Embodiment 2

[0075] Based on the same inventive concept, the embodiment of the present application provides a welding device for printed board assemblies containing fine-pitch connectors. The principle of the device to solve technical problems is the same as a welding method for printed board assemblies containing fine-pitch connectors Similar, the repetition will not be repeated.

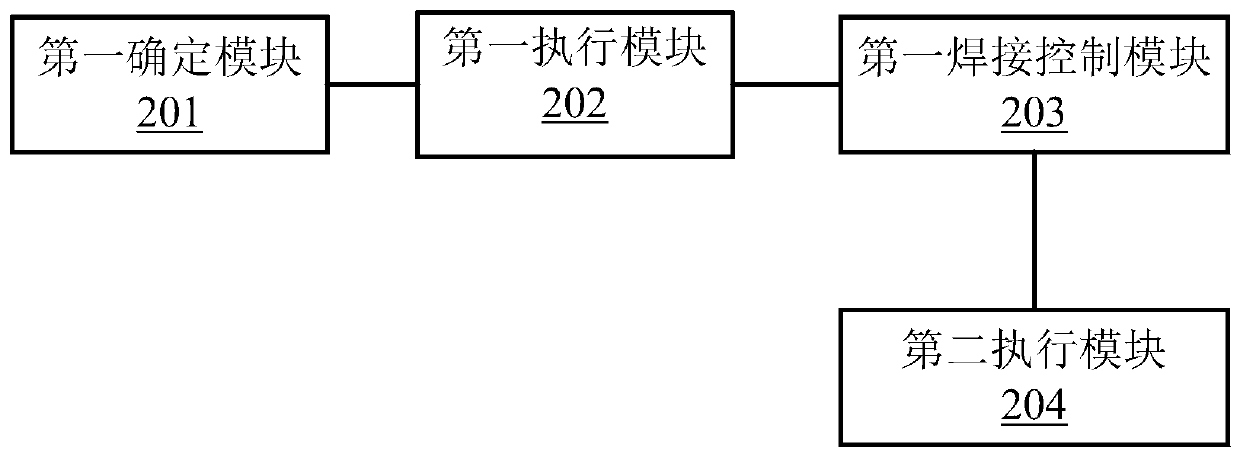

[0076] figure 2 A schematic structural diagram of a soldering device for a printed board assembly including a fine-pitch connector in Embodiment 2 of the present application is shown.

[0077] As shown in the figure, the soldering device of the printed board assembly containing fine-pitch connectors includes:

[0078] The first determination module 201 is configured to determine that the printed board assembly contains a fine-pitch connector with screws whose distance from the pin of the fine-pitch connector is less than a preset first distance threshold;

[0079] The first execution module 202 is used to re...

Embodiment 3

[0096] Based on the same inventive concept, an embodiment of the present application further provides a computer storage medium, which will be described below.

[0097] The computer storage medium stores a computer program thereon, and when the computer program is executed by a processor, the steps of the method for soldering a printed board assembly including a fine-pitch connector as described in Embodiment 1 are implemented.

[0098] The computer storage medium provided by the embodiment of the present application, when performing selective wave soldering of fine-pitch connectors with self-contained screws, uses process screws to assemble the connectors, changing the traditional manual soldering and ordinary wave soldering methods, It solves the problem that the nozzle hits the screw of the connector and the incomplete welding of the pins at the end of the connector during traditional welding, improves the welding quality of the fine-pitch connector, and greatly improves the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com