High heat resistance welding wire for dissimilar steel welding joints

A technology for welding joints and dissimilar steels, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of insufficient high temperature permanent fracture strength, carbon migration, large joint structure, mechanical property gradient, etc., and achieve good The effect of high temperature permanent rupture strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

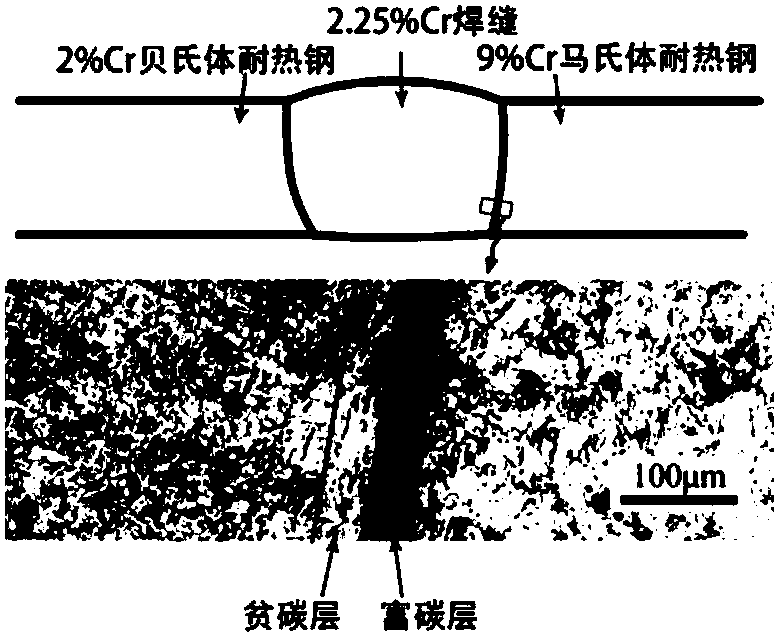

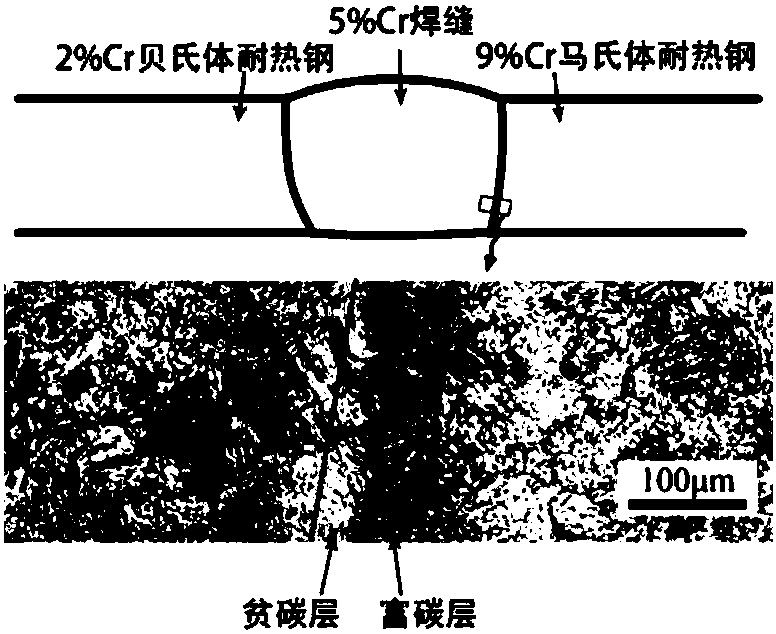

Embodiment 1

[0042] According to the welding wire formula provided in the present invention, a welding wire sample 1# was prepared, and the welding wire formula is shown in Table 2. Welding wire sample 1# is used for welding 9% Cr martensitic heat-resistant steel and 2% Cr bainitic heat-resistant steel, the schematic diagram and local microstructure of the welded joint are shown in figure 2 . The post-weld heat treatment condition is to keep warm at 655-675°C for 20 hours. Depend on figure 2 It can be seen that compared to figure 1 , the dissimilar steel welded joint made by the welding wire of the present invention, the carbon migration phenomenon on the 9% Cr martensitic heat-resistant steel side is significantly improved, the carbon migration degree of the welded joint is significantly reduced, and the composition and structure of the entire welded joint change gradient Reduced, which has a significant effect on improving the high-temperature enduring strength and toughness of the ...

Embodiment 2

[0046] According to the welding wire formula provided in the present invention, welding wire samples 2#, 3#, and 4# were prepared, and the welding wire formula is shown in Table 3. Welding wire samples 2#, 3#, and 4# are used for welding 9% Cr martensitic heat-resistant steel and 2% Cr bainitic heat-resistant steel. The post-weld heat treatment conditions for welding wire samples 2#, 3#, and 4# are at 655-675°C for 20 hours. In the dissimilar steel welded joints produced by welding wire samples 2#, 3#, and 4# in the present invention, the carbon migration phenomenon on the 9% Cr martensitic heat-resistant steel side is significantly improved, and the carbon migration degree of the welded joints is significantly reduced. The change gradient of composition and structure of the whole welded joint is reduced, which has a significant effect on improving the high-temperature durable strength and toughness of the joint.

[0047] Table 3 Chemical Composition of Welding Wire Samples 2...

Embodiment 3

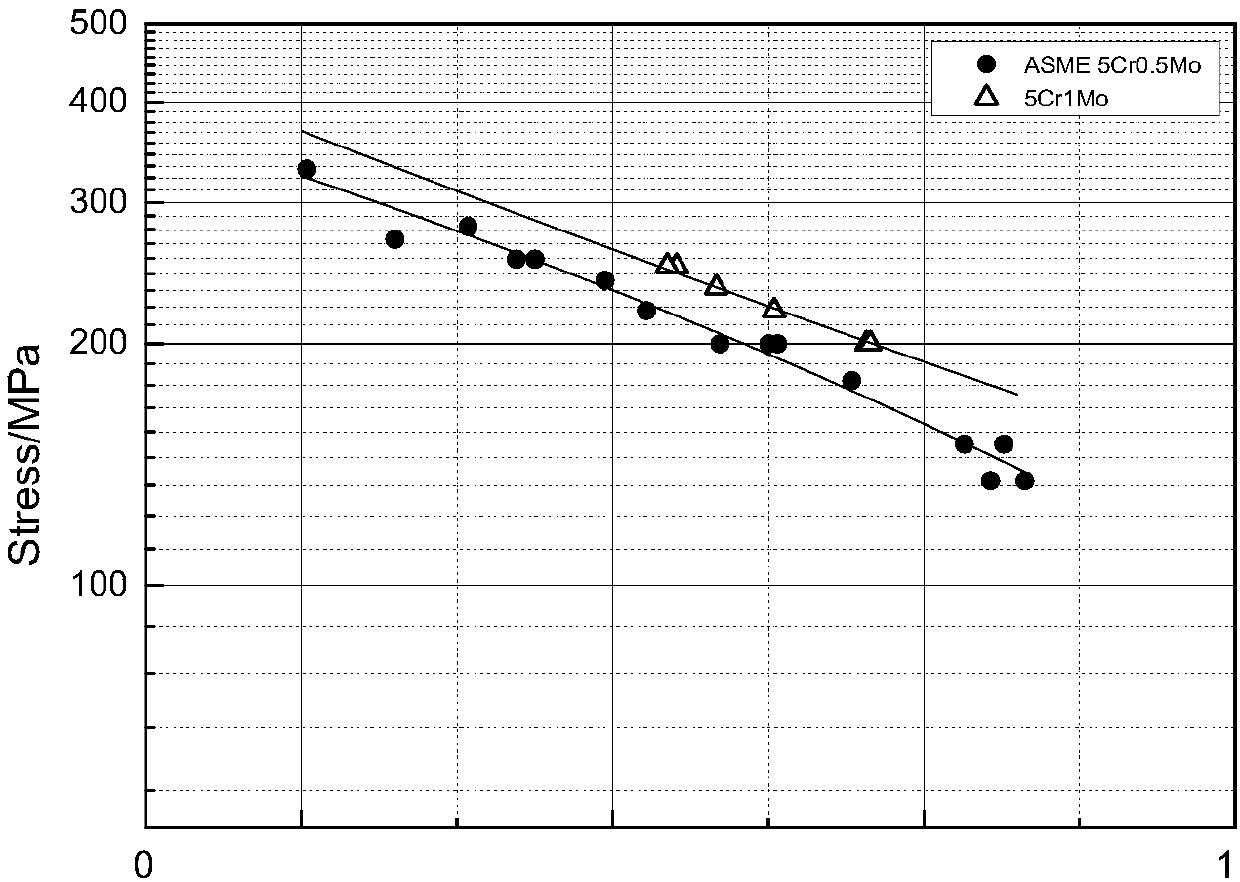

[0050] The weld metal of the dissimilar steel welded joint manufactured using the 5Cr0.5Mo welding wire specified by ASME and the weld metal of the joint in Example 1 are subjected to high-temperature endurance strength tests respectively, and the test results under different temperature and stress combination parameters are summarized in image 3 ,Depend on image 3 It can be seen that the welding wire sample 1# (5Cr1Mo series) prepared in the present invention has higher thermal strength, which is obviously better than 5Cr0.5Mo welding wire.

[0051] In summary, the present invention provides a high thermal strength welding wire for dissimilar steel welding joints, which is a 5Cr1Mo type high thermal strength welding wire, mainly used to connect 9% Cr martensitic heat-resistant steel and 2% Bainite Body heat-resistant steel. Compared with the dissimilar steel joint using 2.25% Cr welding material, the dissimilar steel joint manufactured by using the welding wire provided by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com