Hybrid power drive system

A drive system, hybrid technology, applied in electric braking systems, hybrid vehicles, traction driven by engines, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

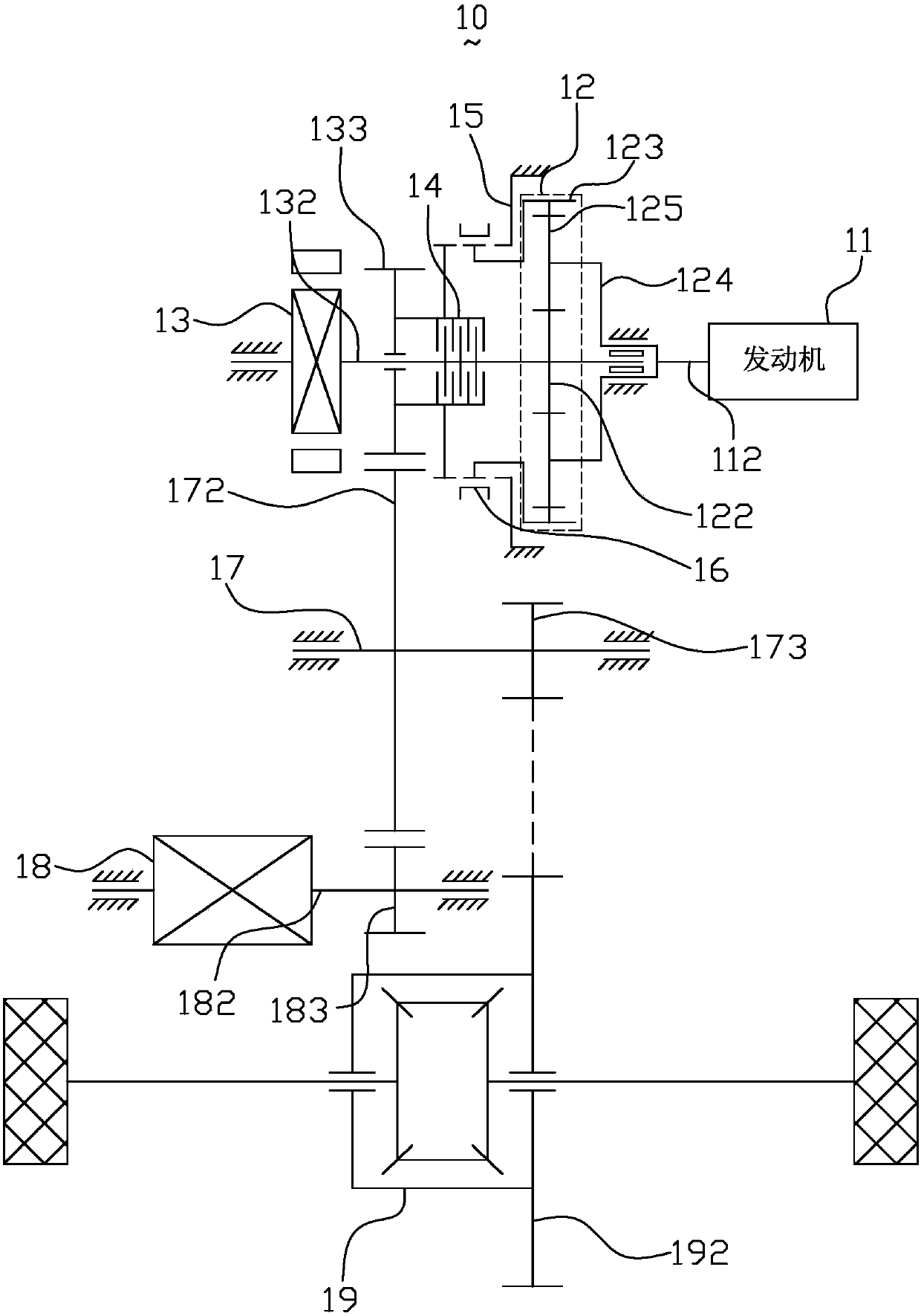

[0042] figure 1 It is a schematic structural diagram of the hybrid drive system according to the first embodiment of the present invention. like figure 1 As shown, the hybrid drive system 10 includes an engine 11, a planetary gear arrangement 12, a first electric machine 13, a clutch gear arrangement, a switch arrangement, an engagement arrangement, an intermediate shaft 17, a second electric machine 18, a differential 19 and a power battery (Fig. not shown).

[0043] The engine 11 has an engine output shaft 112 . In this embodiment, the engine 11 is, for example, a gasoline engine or a diesel engine.

[0044] The planetary gear device 12 includes a first rotation element, a second rotation element, and a third rotation element. The first rotating element is connected to the first motor 13 , the second rotating element is connected to the engine 11 , and the third rotating element is connected to the engagement device 16 . In this embodiment, the first rotation element 12...

no. 2 example

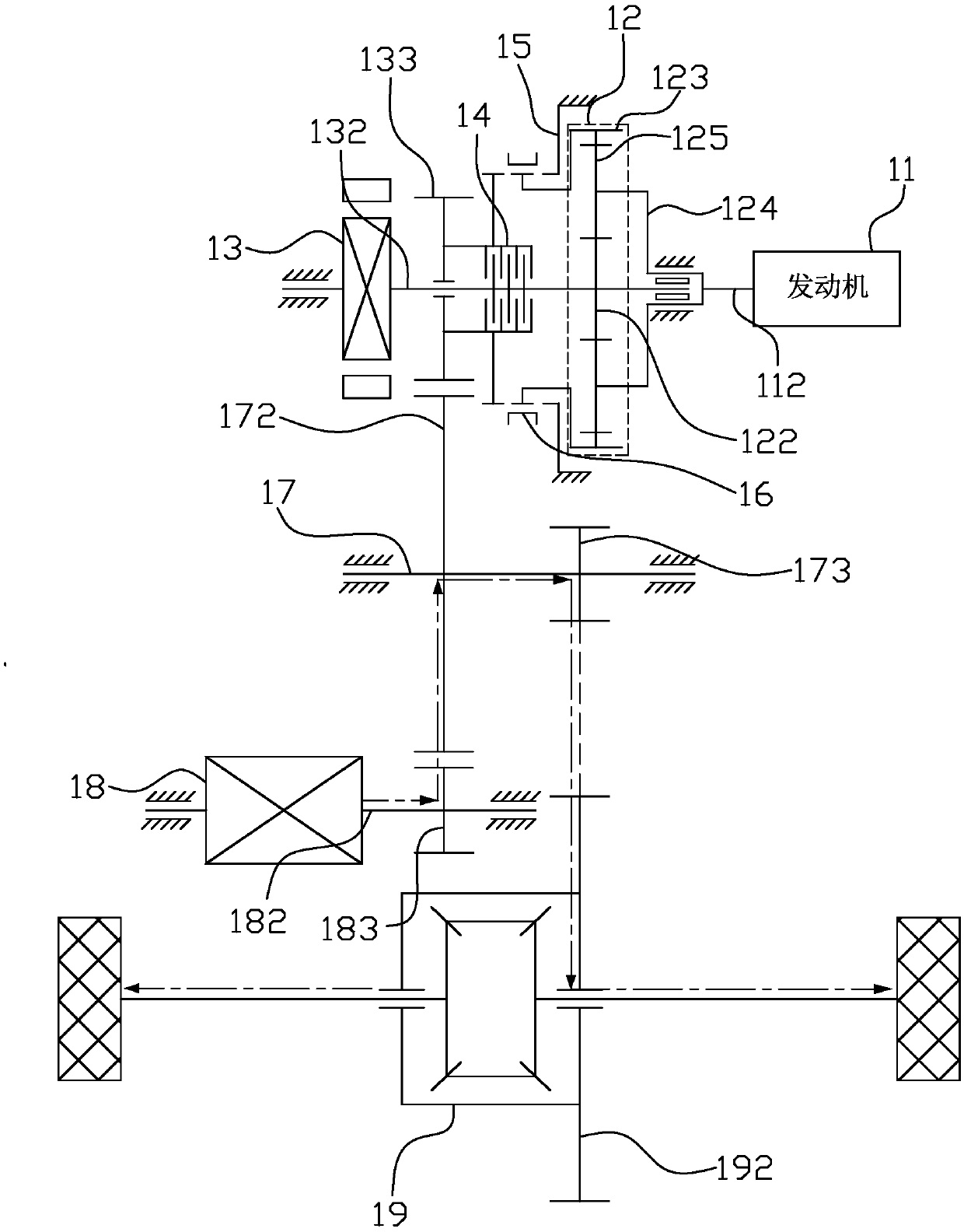

[0068] Figure 11 It is a schematic structural diagram of the hybrid drive system according to the second embodiment of the present invention. like Figure 11 As shown, the structure of the hybrid drive system 10 of this embodiment is substantially the same as that of the hybrid drive system 10 of the first embodiment, and the difference lies in the connection relationship between the engine 11 and the planetary gear device 12 and the connection between the engagement device and the planetary gear device 12 Relationships are different.

[0069] Specifically, in this embodiment, the first rotating element is a sun gear, the second rotating element is a ring gear, the third rotating element is a planet carrier, the engaging device is a synchronizer, and the switching device is a brake or a one-way clutch, that is, Said, the ring gear 123 is connected with the engine output shaft 112, the synchronizer 16 is fixed on the planet carrier 124, the synchronizer 16 includes a left st...

no. 3 example

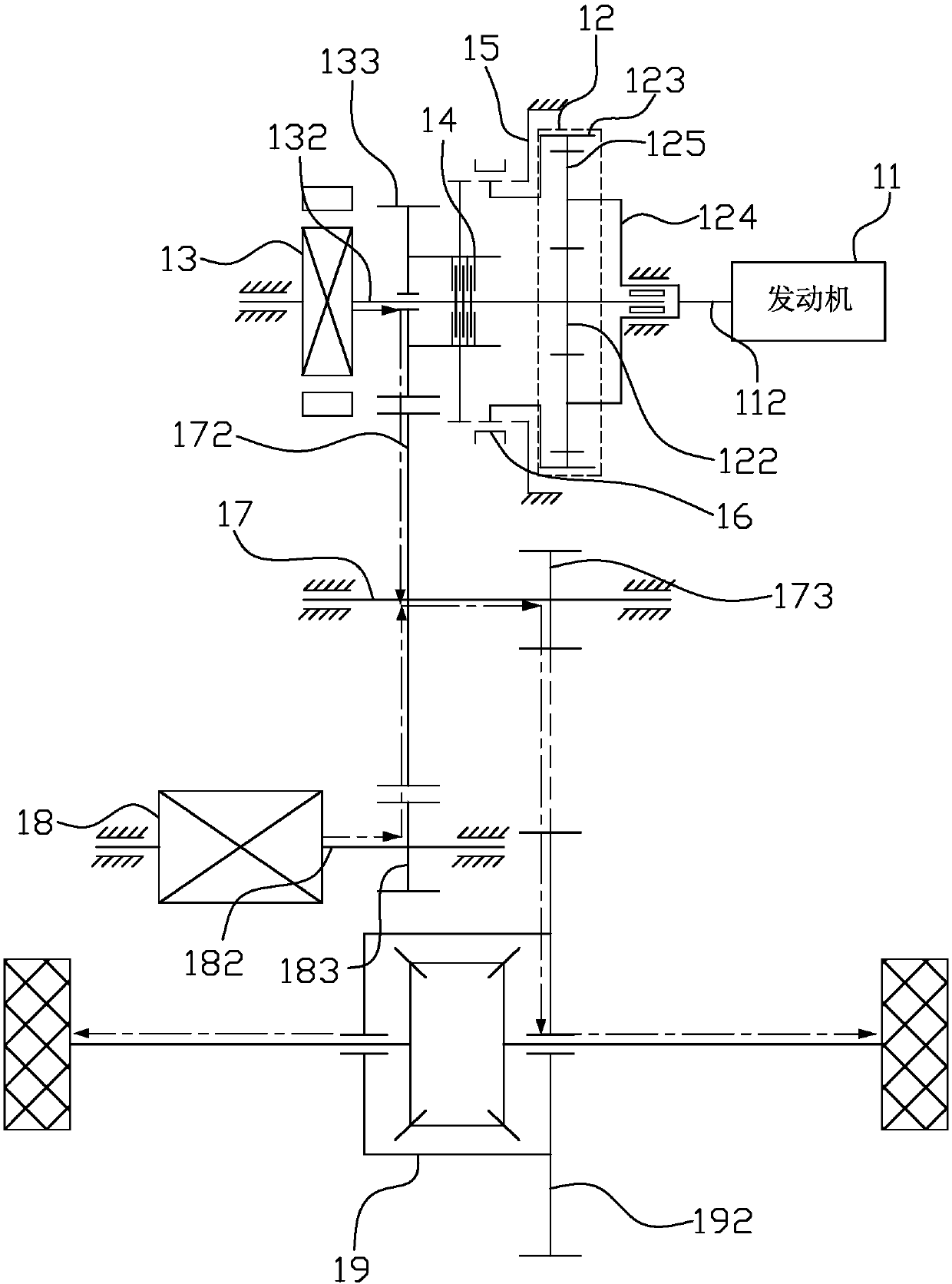

[0072] The hybrid drive system 10 of the present embodiment has substantially the same structure as the hybrid drive system 10 of the first embodiment, except that the connection relationship between the engine 11 and the planetary gear device 12 and the connection relationship between the engagement device and the planetary gear device 12 are different.

[0073] Specifically, the first rotating element is a planet carrier, the second rotating element is one of the sun gear and the ring gear, the third rotating element is the other of the sun gear and the ring gear, the engaging device is a synchronizer, and the switching device is a brake or a one-way clutch. For the connection relationship and driving method of the components of the hybrid drive system 10, please refer to the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com