Harmless treatment equipment and method for treating livestock and poultry manure through same

A technology for harmless treatment of livestock and poultry manure, applied in climate change adaptation, preparation of organic fertilizer, organic fertilizer and other directions, can solve the problems of low utilization rate of heat source, no cooling and cooling of deodorization equipment, and increased deodorization cost, etc. It is easy to maintain the fermentation temperature, improve the overall thermal insulation effect, and facilitate maintenance and management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

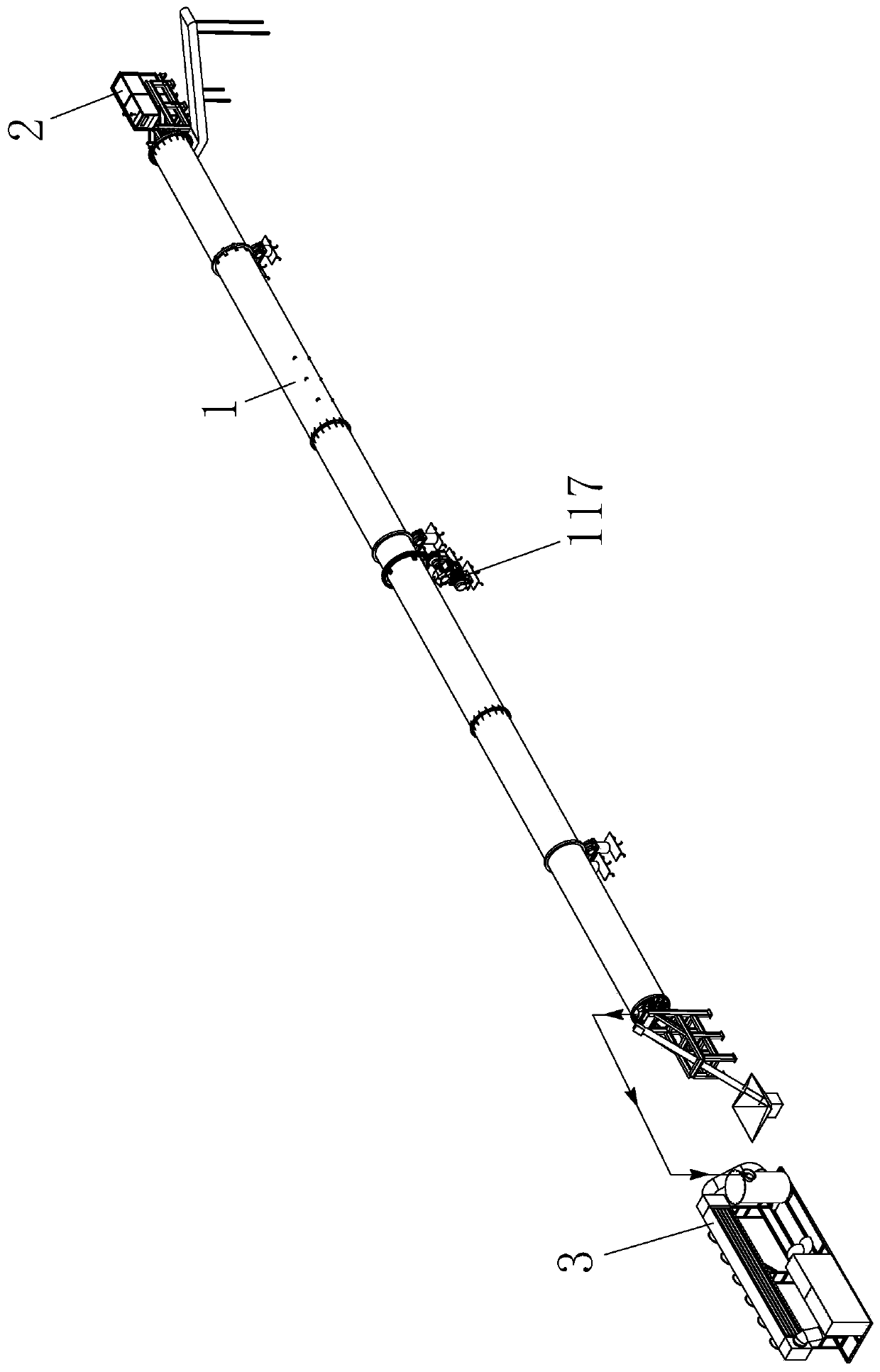

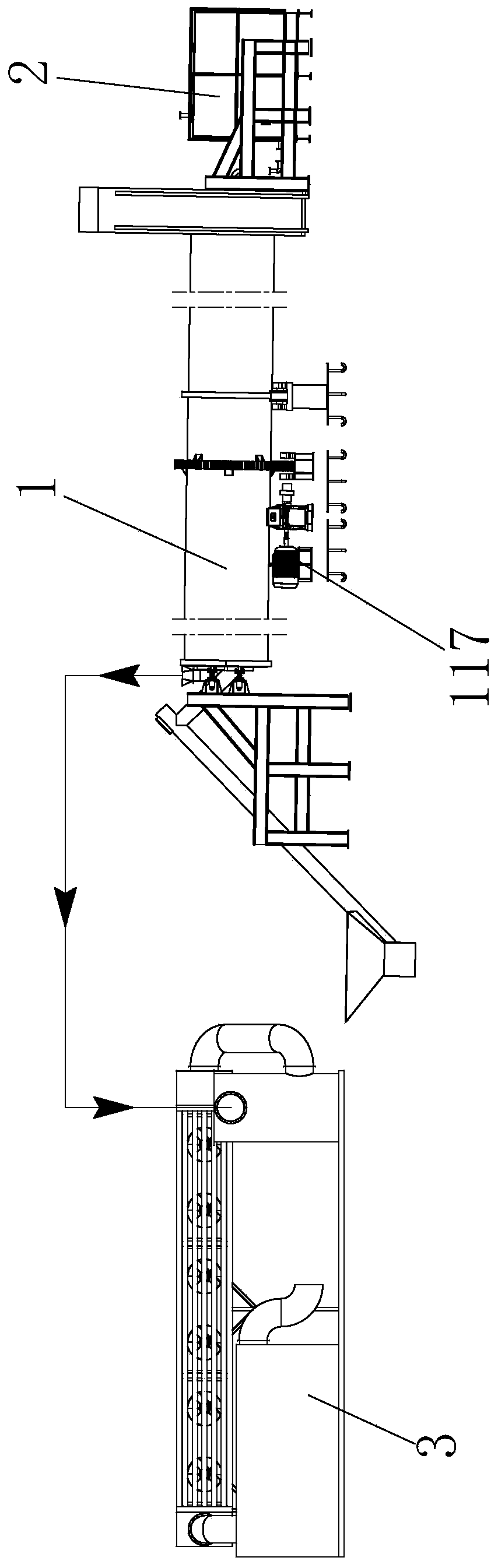

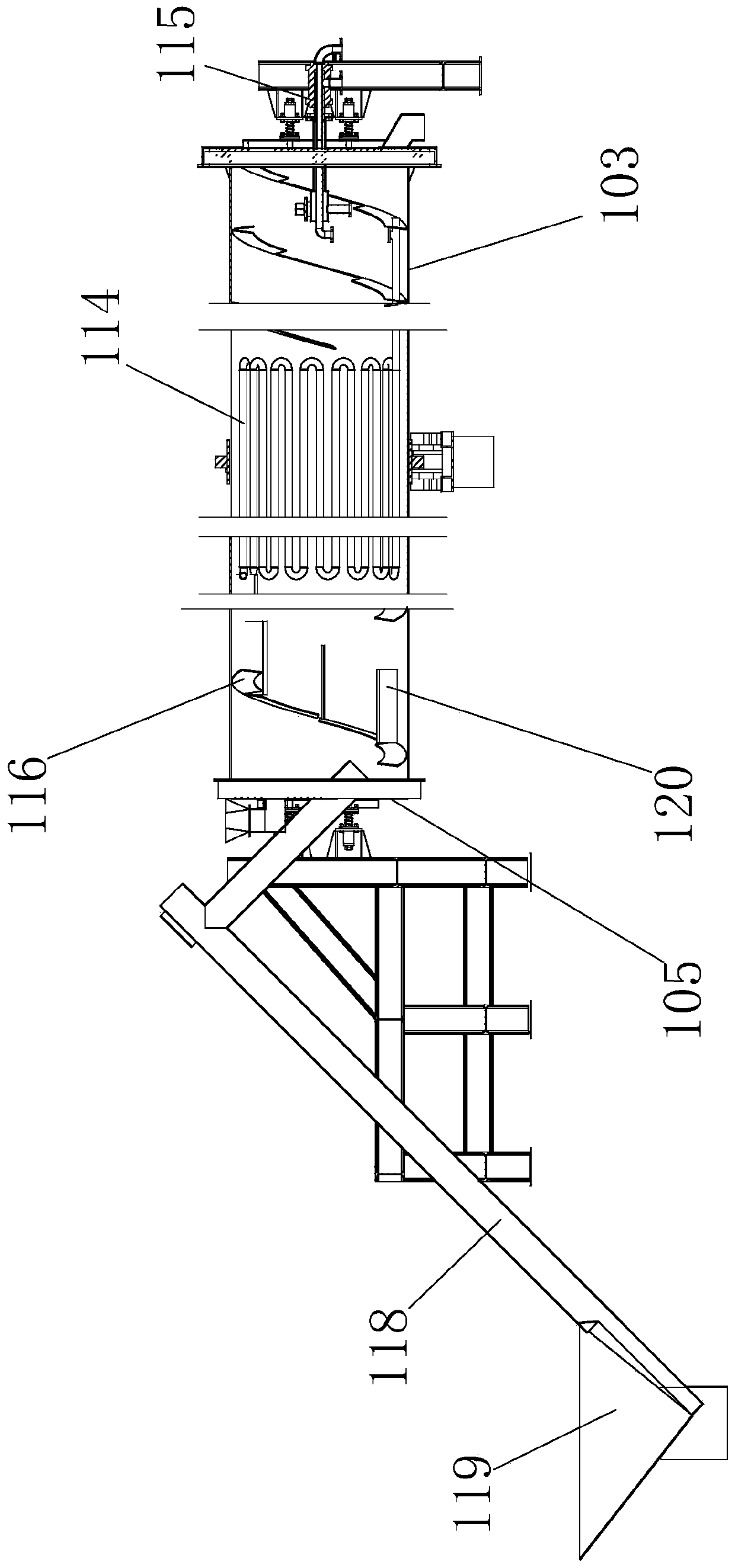

[0048] Such as Figure 1-9 As shown, a method for treating livestock and poultry manure with harmless treatment equipment, the harmless treatment equipment includes a drum device 1, a heat conduction oil furnace heating device 2 and a condensation deodorization device 3;

[0049] The drum device 1 includes a feeding tank 119, a screw feeding conveyor 118, a cylinder 103 and a geared motor 117 that drives the rotation of the cylinder 103, and the two ends of the cylinder 103 are respectively provided with connection end caps 105 fixedly connected to the ground. The body 103 is supported on the ground by multiple sets of supporting wheels, and both ends can rotate freely in the connecting end cover 105. The lower end of the screw feeding conveyor 118 is connected with the feeding pool 119 in the ground, and the lower end of the screw feeding conveyor 118 is connected to the upper end. Then it communicates with the connecting end cover 105 of the feeding end of the cylinder 103. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com