Continuous preparation method of benzyl zinc halide and derivatives of benzyl zinc halide

A technology of benzyl zinc halide and derivatives, applied in the direction of zinc organic compounds, can solve the problems of inapplicability and scale-up production, and achieve the effect of avoiding the risk of spraying materials and improving contact efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

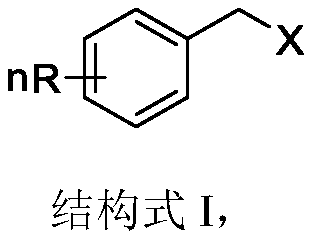

[0023] As analyzed in the background technology of the present application, the technical scheme of direct insertion of zinc atoms into carbon-halogen bonds in the prior art is carried out by batch reaction, which is prone to material accumulation and causes the risk of material spraying, thus limiting its use in industrial scale-up production Applications. In order to solve the risk of spraying, metal magnesium / lithium chloride / zinc chloride was used to realize the insertion of zinc atoms in benzyl halohydrocarbons, but due to the solubility limitations of lithium chloride and zinc chloride in organic solvents , leading to the need for high-temperature processing, which also limits the application of this route in industrial scale-up production. In order to solve the problem that the preparation method of benzyl zinc halide in the prior art is not suitable for scale-up production, the application provides a continuous preparation method of benzyl zinc halide and derivatives t...

Embodiment 1

[0040] Under the protection of nitrogen, add 4.45Kg of tetrahydrofuran, 500g of 4-fluorochlorobenzyl, 18.8g of trimethylchlorosilane, and 32.5g of 1,2-dibromoethane into a 10L four-necked bottle, and stir for 10-20 minutes to form a liquid reaction materials.

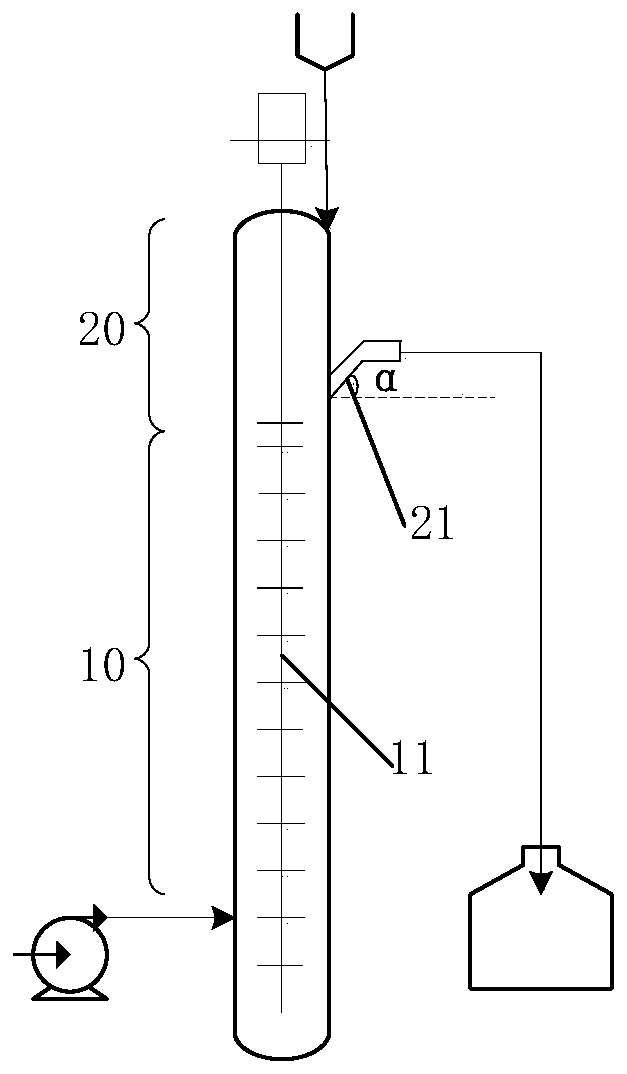

[0041] use figure 1 The columnar reactor shown is for continuous reaction, wherein the temperature control range of the heating section 10 of the columnar reactor is 65-75°C, the temperature control range of the cooling section 20 is 15-25°C, and the product overflow port is set at the cooling The section 20 is close to one end of the heating section 10, the angle α between the drainage tube 21 and the outer wall is 25°, and the stirring speed is adjusted between 100-200r / min. Turn on the feed pump to provide the liquid reaction material to the heating section 10, and turn on the continuous solid feeder to provide the zinc powder to the heating section 10, wherein the flow rate of the liquid reaction material is contro...

Embodiment 2

[0043] Under the protection of nitrogen, add 4.45Kg of tetrahydrofuran, 500g of 4-fluorochlorobenzyl, 18.8g of trimethylchlorosilane, and 32.5g of 1,2-dibromoethane into a 10L four-necked bottle, and stir for 10-20 minutes to form a liquid reaction materials.

[0044] use figure 1 The columnar reactor shown is for continuous reaction, wherein the temperature control range of the heating section 10 of the columnar reactor is 65-75°C, the temperature control range of the cooling section 20 is 15-25°C, and the product overflow port is set at the cooling The section 20 is close to one end of the heating section 10, and the angle α between the drainage tube 21 and the outer wall is 40°. Turn on the feed pump to provide the liquid reaction material to the heating section 10, and turn on the continuous solid feeder to provide the zinc powder to the heating section 10, wherein the flow rate of the liquid reaction material is controlled to be 12g / min, and the zinc powder feeding rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com