A control method for rapid shutdown of thin plate in a vertical continuous annealing unit

A control method and unit technology, applied in heat treatment process control, manufacturing tools, furnaces, etc., can solve problems such as high reverse temperature in the furnace, large span of deceleration interval, and rise in strip temperature, so as to avoid uneven stress , The control process is simple, and the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

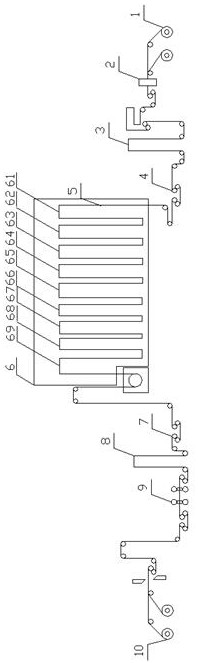

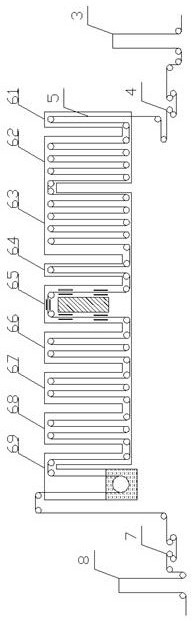

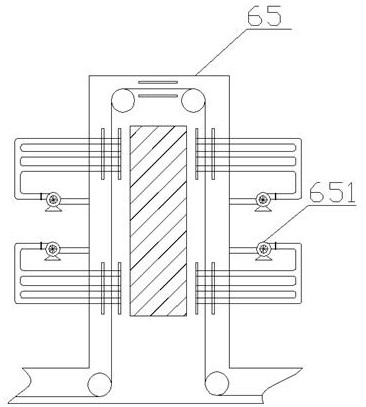

[0024] Embodiment 1: see Figure 1-Figure 4 , a vertical continuous annealing unit thin plate rapid shutdown control method, the control method comprises the following steps:

[0025] S1, the annealing furnace is switched to the cooling mode, and its temperature is controlled;

[0026] S2, reduce unit speed (speed control);

[0027] S3, reduce unit tension (tension control);

[0028] S4. When the unit speed drops below 400mpm, press the stop button;

[0029] S5. After the unit is shut down, the annealing furnace section is unloaded, and the strip steel is conveyed to the annealing furnace to ensure that the strip steel before and after the annealing furnace is slack.

[0030] The specific operation of the temperature control in the step S1 is as follows: when an abnormal situation occurs in the production, the unit needs to slow down. If the running speed of the strip is directly reduced, the temperature of the strip will rise locally. Due to the high temperature of the ann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com