Novel high-efficiency low-NOx-emission combustor

A burner, high-efficiency technology, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of increasing the longitudinal non-uniformity coefficient of the combustion chamber, increasing the outlet temperature of the combustion chamber, and decreasing the heat load of the radiant chamber. Improve the temperature field distribution, reduce the furnace outlet temperature, and strengthen the effect of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

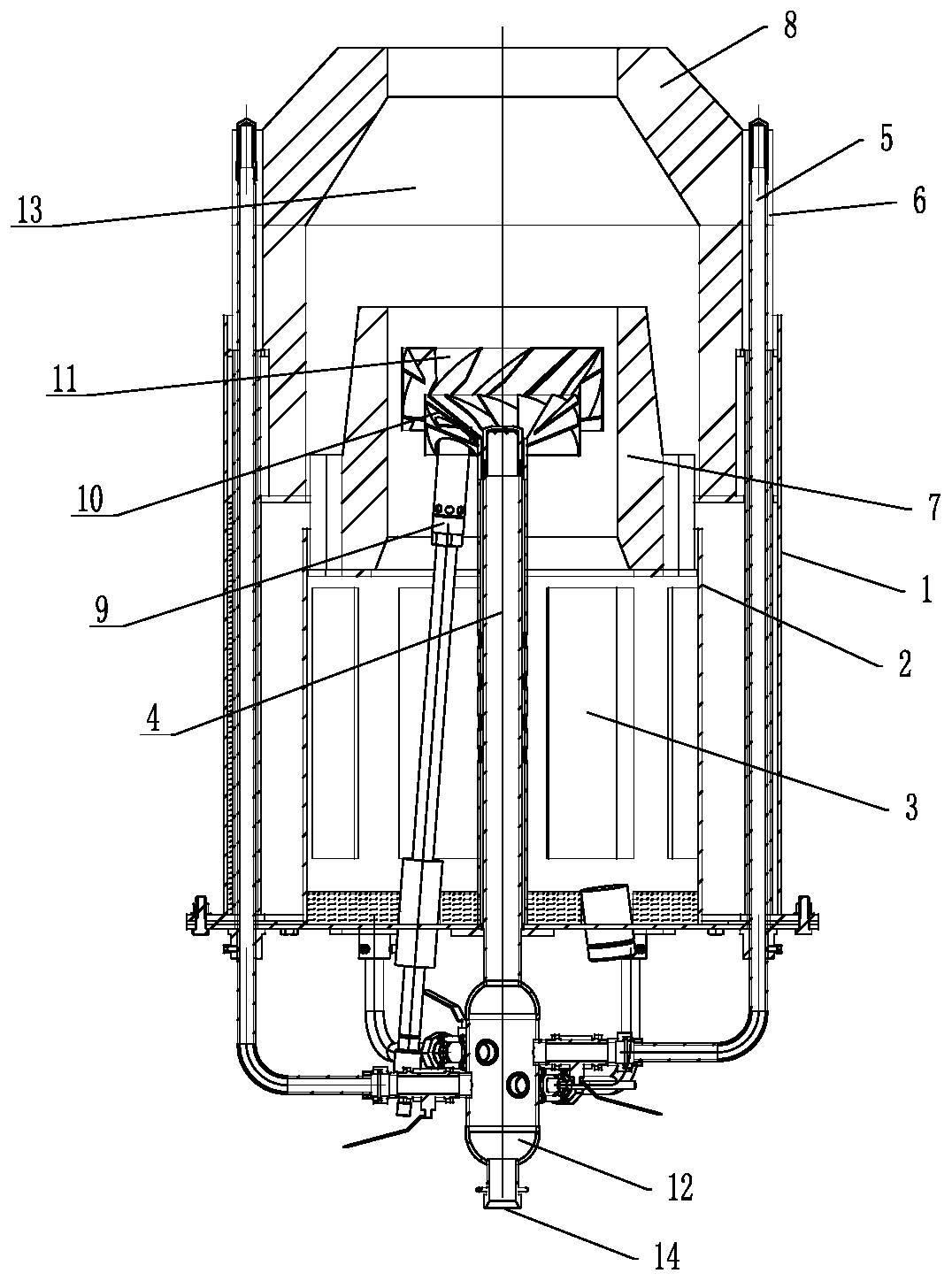

[0026] In order to further illustrate the technical means and effects adopted by the present invention to achieve the intended purpose, a novel high-efficiency low-NO X The burner is described in detail.

[0027] In the description of the present invention, it should be noted that the orientation or positional relationship indicated by the terms "upper", "lower", "left", "right", etc. is based on the orientation or positional relationship of the drawings, and is only for the convenience of description The present invention and simplified description do not indicate or imply that the device or element referred to must have a specific orientation, be constructed and operate in a specific orientation, and thus should not be construed as limiting the present invention.

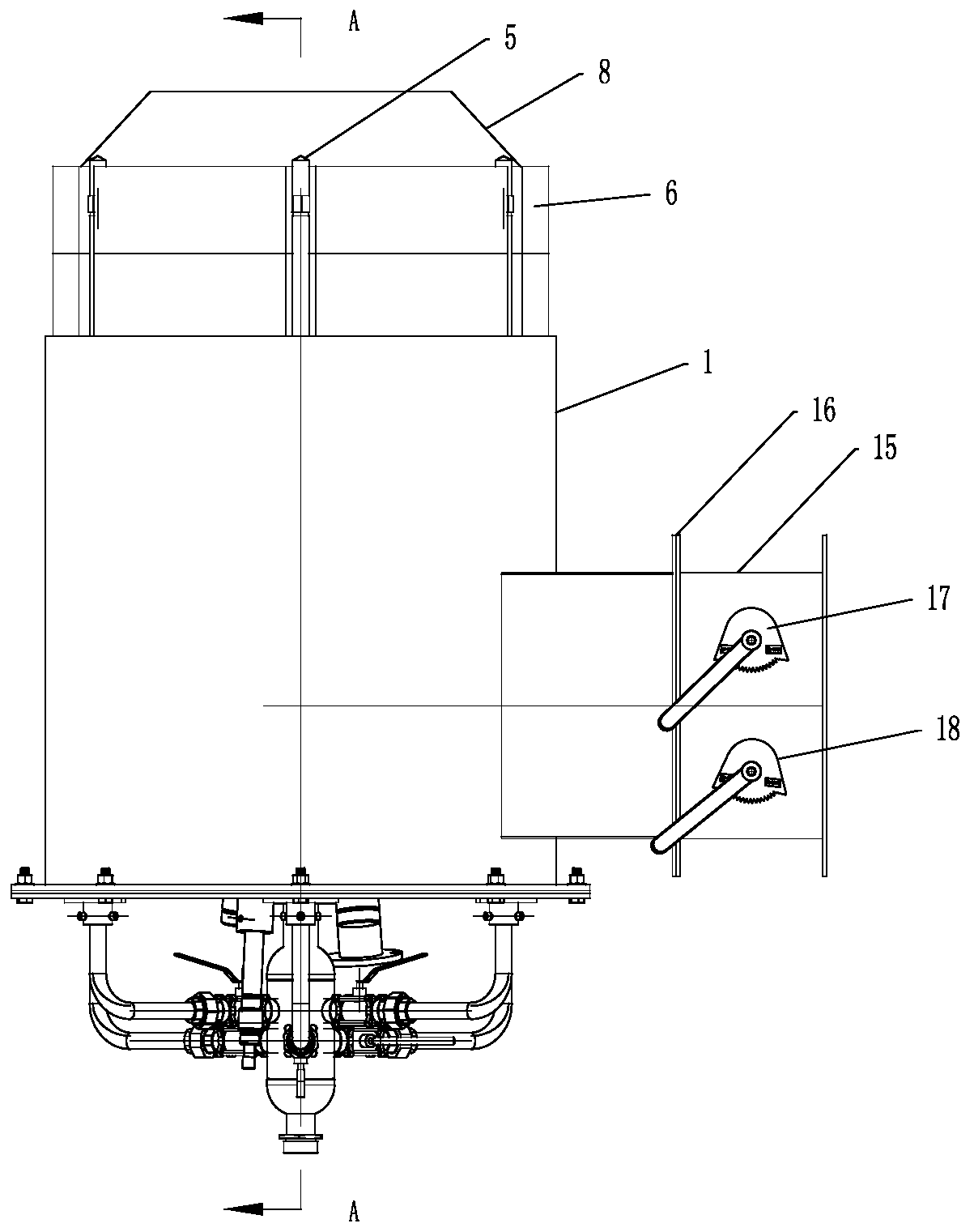

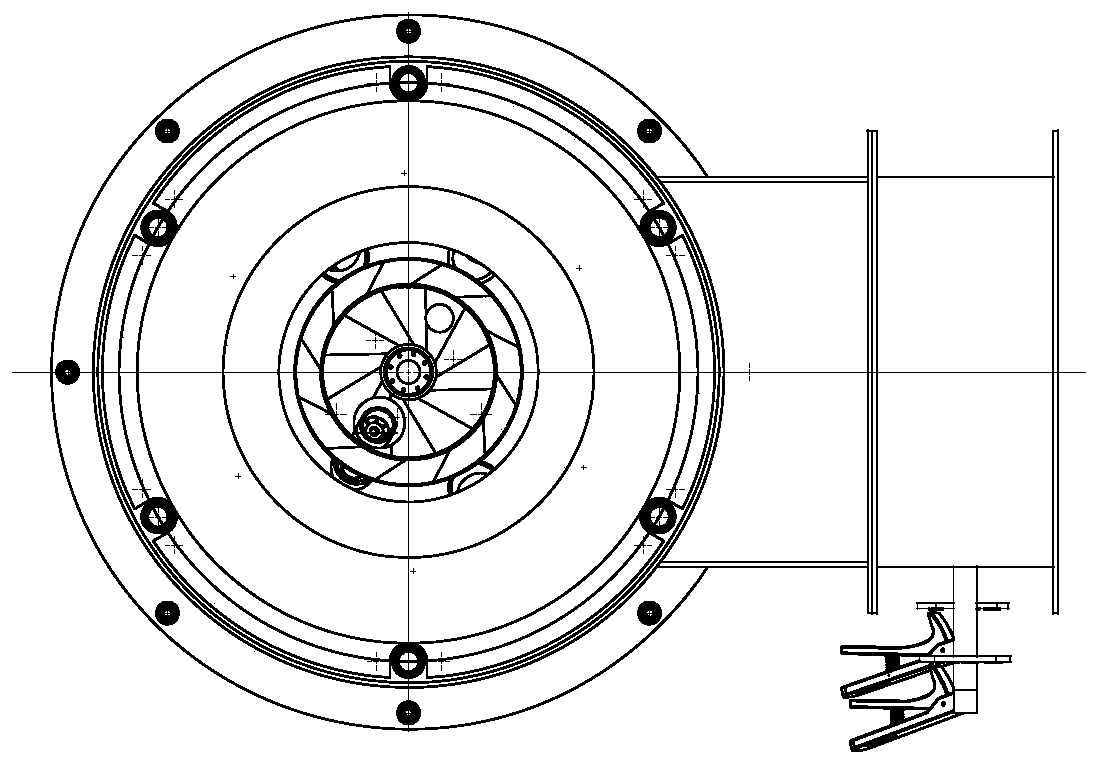

[0028] A new type of high efficiency and low NO X The burner includes a shell 1, a main fuel spray gun 4, a secondary fuel spray gun 5, a fire brick 6, a brazier brick 7, a shut-off brick 8, and an ever-bright la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com