Aero-engine blade test piece nondestructive testing method based on terahertz technology

A technology for aero-engine and non-destructive testing, which is used in measurement devices, complex mathematical operations, instruments, etc., can solve the problems of low imaging resolution and low detection accuracy, and achieves to overcome the low detection accuracy and improve the signal-to-noise ratio and imaging resolution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050]The technical solution of the present disclosure will be described in detail below with reference to the drawings and embodiments.

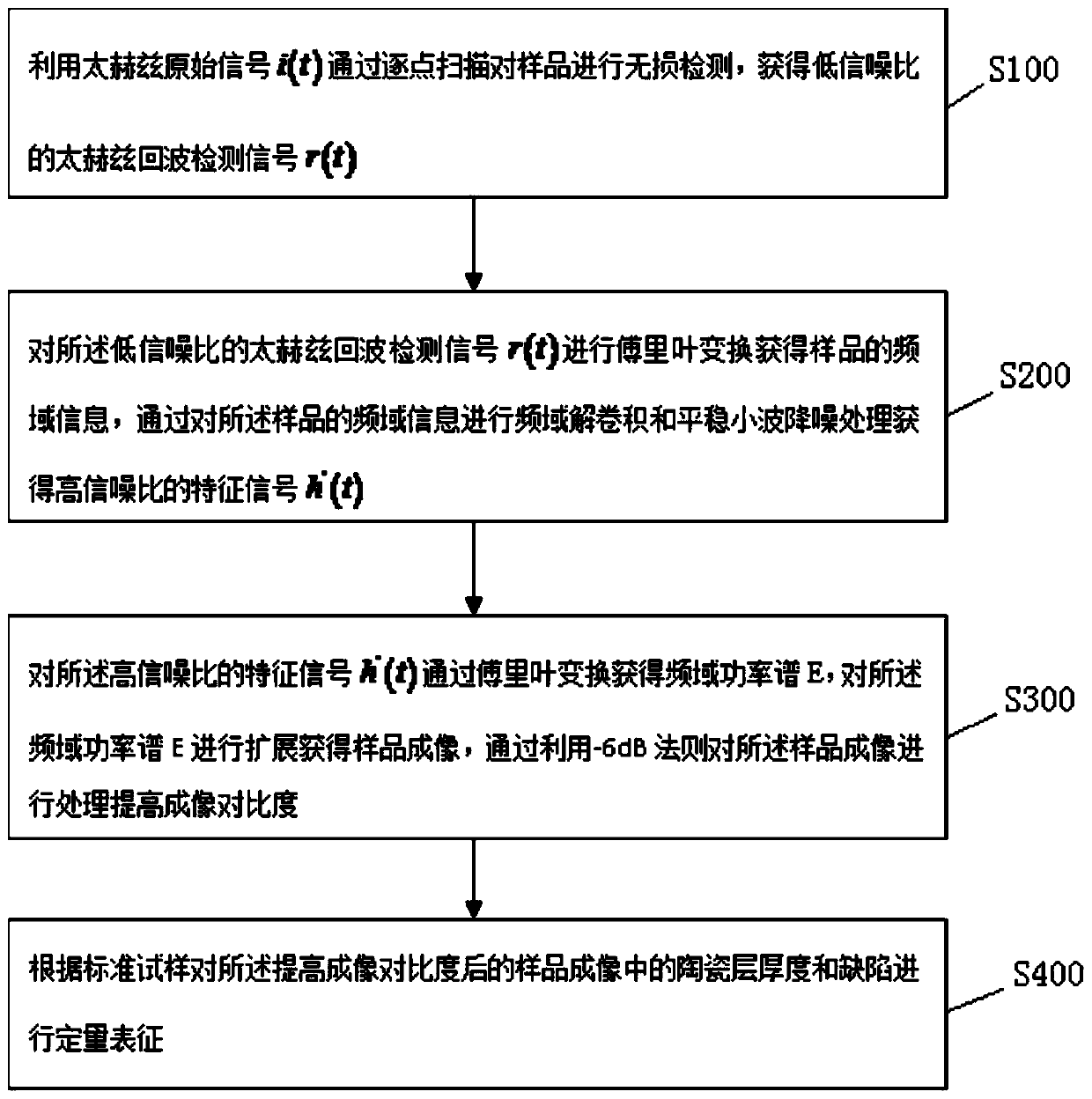

[0051] Such as figure 1 As shown, a non-destructive testing method for aero-engine blade specimens based on terahertz technology includes the following steps:

[0052] S100: Using the terahertz signal to perform non-destructive testing on the sample, and obtaining the original terahertz detection signal with a low signal-to-noise ratio;

[0053] S200: Perform Fourier transform on the terahertz original detection signal with low signal-to-noise ratio to obtain the frequency domain information of the sample, and obtain high The characteristic signal of the signal-to-noise ratio;

[0054] S300: Obtain a frequency-domain power spectrum by Fourier transforming the characteristic signal with a high signal-to-noise ratio, expand the frequency-domain power spectrum to obtain a sample image, and improve the image by processing the sample image usi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com