Lithium battery negative pole piece with excellent cycle performance and manufacturing method thereof, and lithium ion battery

A technology of negative pole piece and deionized water, which is applied in the direction of electrode manufacturing, battery electrodes, active material electrodes, etc., can solve the problems of silicon negative electrode material irreversible capacity loss, poor conductive contact performance, material pulverization, etc., to improve the irreversible capacity Loss, improve adhesion, improve the effect of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

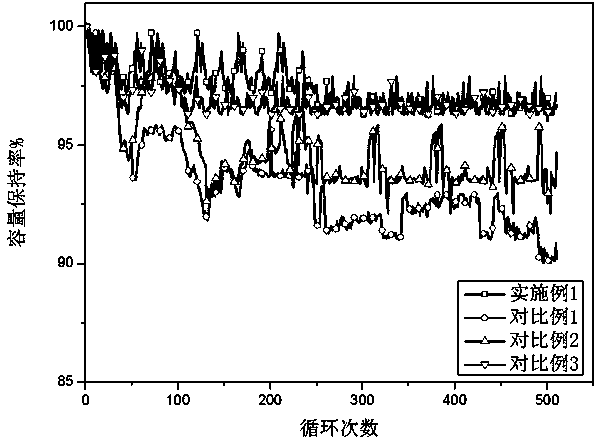

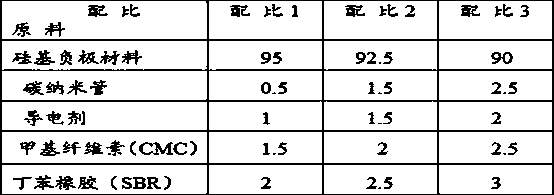

Examples

preparation example Construction

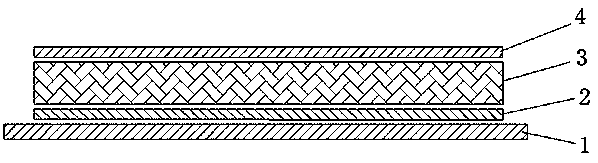

[0039] The present invention also proposes the preparation method of the negative electrode sheet, and the preparation steps of its embodiment 1 are as follows (see figure 1 ):

[0040] Step 1, preparation of adhesion layer

[0041] Select cyclopentadithiophene-benzoic acid plus deionized water, prepare according to the weight ratio of 2:98, mix and stir to form a slurry. According to the needs, the conductive adhesive layer slurry is composed of 2~5% conductive polymer binder and 95~98% deionized water. For example, the ratio of conductive polymer binder and deionized water can also be selected : 5 : 95 or 3.5 : 96.5 etc. The slurry is coated on the surface of the negative electrode current collector 1 - the copper foil, and the thickness of the conductive adhesive layer 2 is controlled to be 2-10um. Put the current collector coated with the conductive adhesive layer slurry at 80°C for 15 minutes and then bake it to a semi-dry state, so that the conductive adhesive layer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com