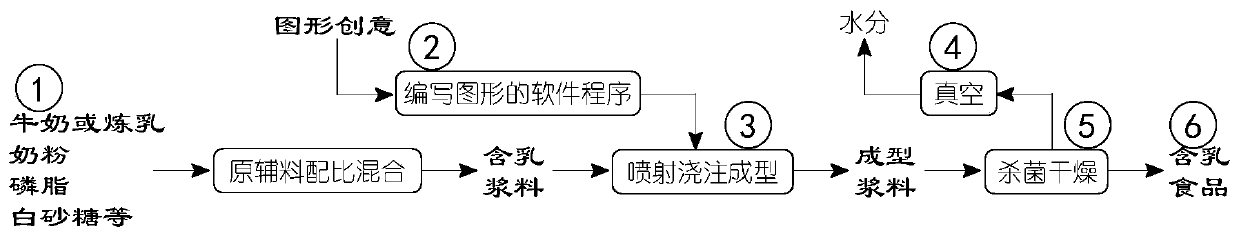

Preparation process of milk-containing food molded by spray casting

A technology of pouring molding and preparation technology, which is applied in the direction of dairy products, other dairy products, milk preparations, etc. It can solve the problems of mold shape limitation, difficult to control moisture, single product shape, etc., and achieve improved fluidity, rich taste, creamy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A preparation process of a jet-casting milk-containing food (sugar-containing milk flower), the raw and auxiliary materials, in parts by weight, are made of the following components: 445 parts of milk, 34 parts of milk powder, 4.5 parts of phospholipid, white 13.5 parts of granulated sugar, the dry basis of the above raw and auxiliary materials adds up to 100%. (See Table 7 for details)

[0056] Described preparation process, it comprises the steps:

[0057] (1) Mix the components of the raw and auxiliary materials weighed in proportion in a high-speed mixer to obtain a milk-containing slurry; the mixing time is 15 minutes, and the speed of the high-speed mixer is 1350 rpm.

[0058] Specifically, milk is first mixed with phospholipids and white granulated sugar, and then mixed with milk powder after all of them are melted; wherein, the milk is concentrated to a water content of 45% before use, so as to make the slurry of various raw and auxiliary materials The water c...

Embodiment 2

[0076] Embodiment 2 (milk flower)

[0077] A preparation process (sugar-free type) of a jet-casting milk-containing food, ingredients list (by weight): 565 parts of milk, 34 parts of milk powder, 4.5 parts of phospholipid, the dry basis of the above raw and auxiliary materials is 100%. (See Table 7)

[0078] The preparation process of the milk-containing food is the same as in Example 1 as described above.

Embodiment 3

[0079] Embodiment 3 (milk flower)

[0080] A preparation process of a spray-cast milk-containing food, the only difference from Example 1 is that the ingredients list (in parts by weight): 86 parts of milk powder, 4.5 parts of phospholipids, 13.5 parts of white sugar, 37.4 parts of purified water, The total dry basis of the above raw and auxiliary materials is 100%. (See Table 7)

[0081] (1) Mix the components of the raw and auxiliary materials weighed in proportion in a high-speed mixer to obtain a milk-containing slurry; the mixing time is 15 minutes, and the speed of the high-speed mixer is 1350 rpm.

[0082] The water content in the milk-containing slurry was 29.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com