Soldering flux layered soldering pen

A layered, flux technology, applied in welding equipment, welding media, welding/cutting media/materials, etc., can solve the problems of reducing welding heat input, increasing the intensity, weakening the protection effect, etc., achieving low price and flux composition. Simple, smooth and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

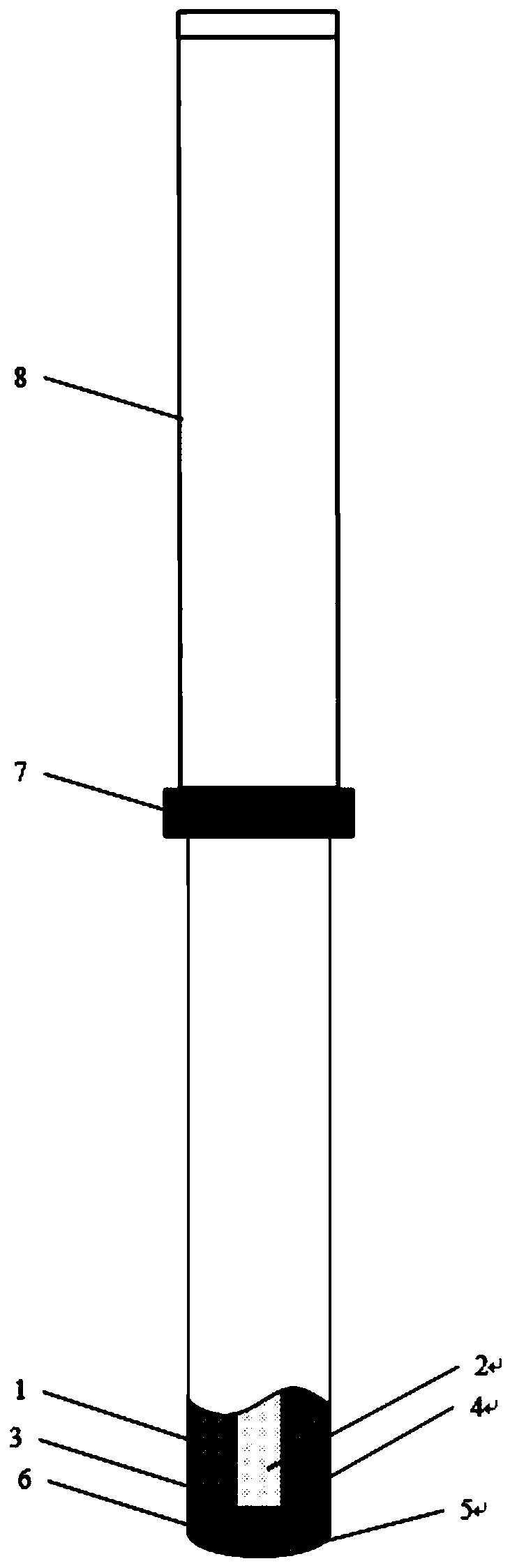

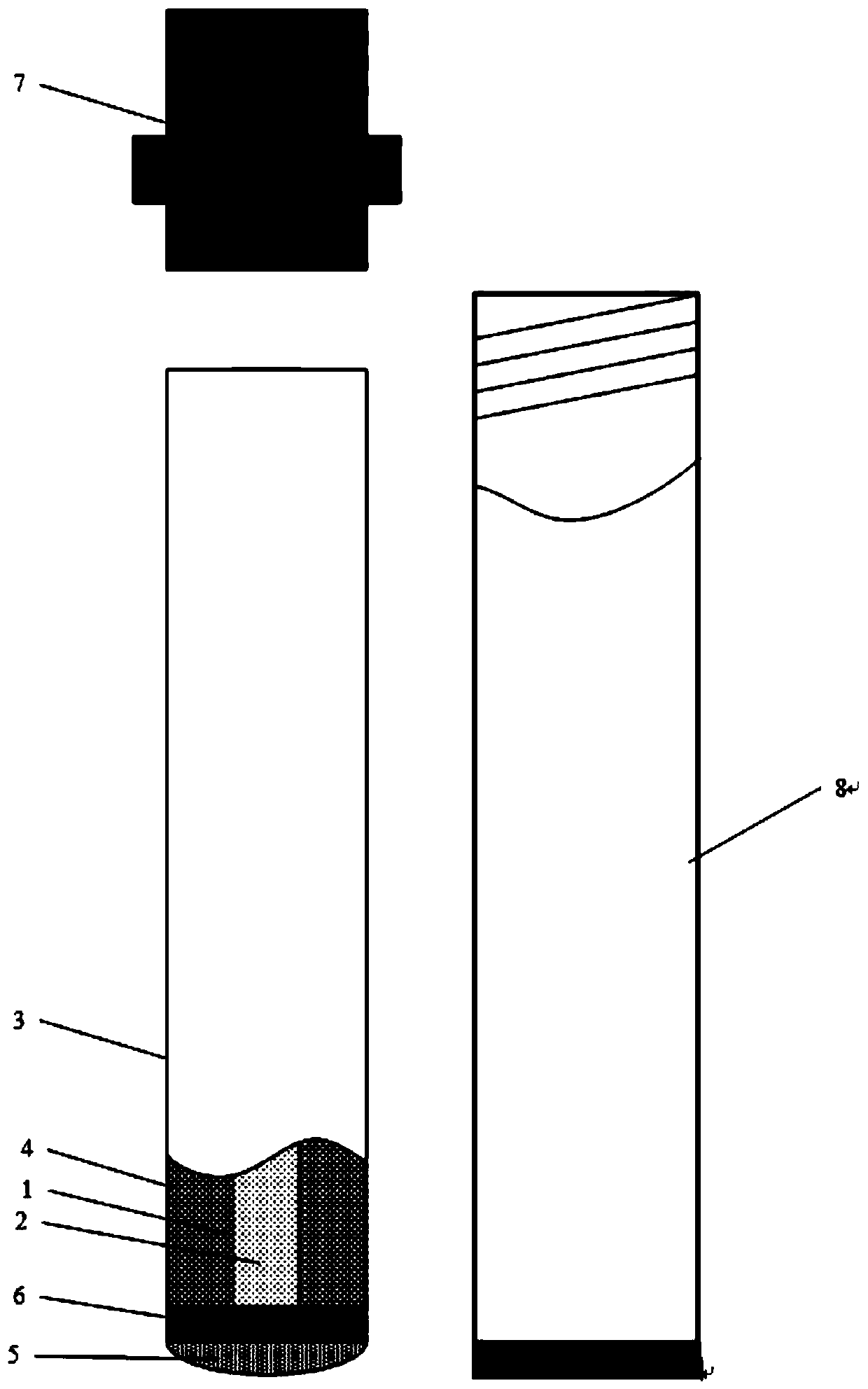

[0033] A flux layered soldering pen, the inner layer flux is composed of slagging agent and alloy agent, and the outer layer flux is composed of high heat agent and a small amount of inner layer flux. The inner flux composition is: CaF 2 Powder 40wt.%, CaSO 4Powder 20wt.%, borax 5wt.%, ferromanganese powder 15wt.%, ferronickel powder 20wt.%; the outer flux composition is 90wt.% high heat flux and 10wt.% inner flux, wherein the high heat flux composition is CuO Al powder 75wt.%, Al powder 25wt.%. Dry each raw material in an electric heating constant temperature blast drying oven (T=80°C) for 6 hours; weigh the raw materials according to the mass percentage, mix them in a high-speed mixer, and sequentially prepare the inner layer flux and the outer layer flux; Put the inner layer of flux into the paper drug tube with a diameter of 5mm and a length of 200mm, then put a paper drug tube with a diameter of 12mm and a length of 200mm outside the inner layer of drug tube, and fill t...

Embodiment 2

[0036] A flux layered soldering pen, the inner layer flux is composed of slagging agent and alloy agent, and the outer layer flux is composed of high heat agent and a small amount of inner layer flux. The inner flux composition is: CaF 2 Powder 25wt.%, CaSO 4 30wt.% powder, 10wt.% borax, 15wt.% ferromanganese powder, 20wt.% ferronickel powder; the outer flux composition is 88wt.% high heat flux and 12wt.% inner flux, wherein the high heat flux composition is CuO Al powder 80wt.%, Al powder 20wt.%. The particle size of each raw material is between 150 and 200 mesh. Dry each raw material in an electric heating constant temperature blast drying oven (T=80°C) for 8 hours; weigh the raw materials according to the mass percentage, mix them in a high-speed mixer, and sequentially prepare the inner layer flux and the outer layer flux; Put the inner layer flux into the paper drug tube with a diameter of 4mm and a length of 220mm, then put the paper drug tube with a diameter of 11mm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com