Grinding machine for toughened glass production

A tempered glass and grinding machine technology, which is applied to machine tools suitable for grinding workpiece planes, portal grinding machines, grinding machines, etc., can solve the problems of glass grinding, inconvenient glass positioning, and no glass positioning and positioning device, etc., to achieve Easy sanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

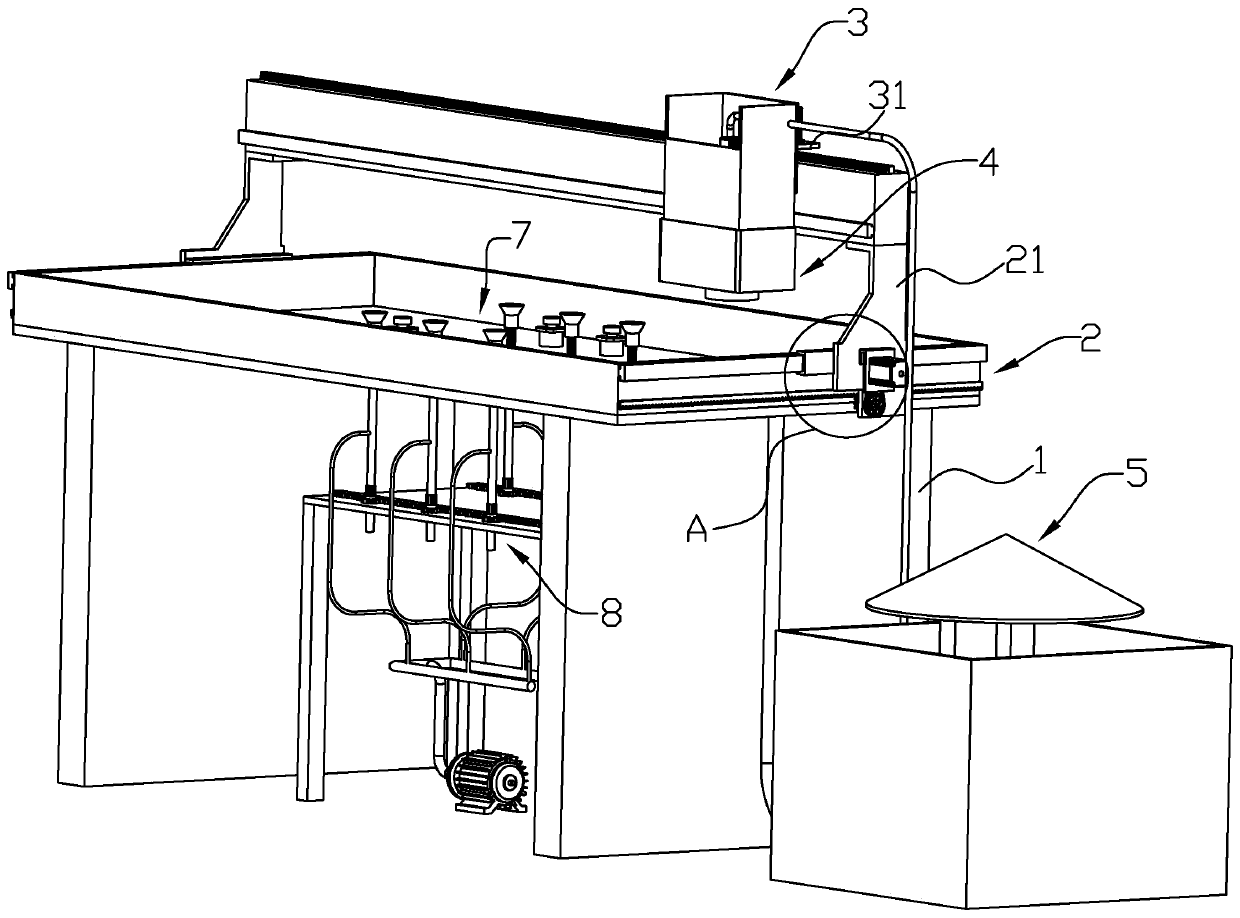

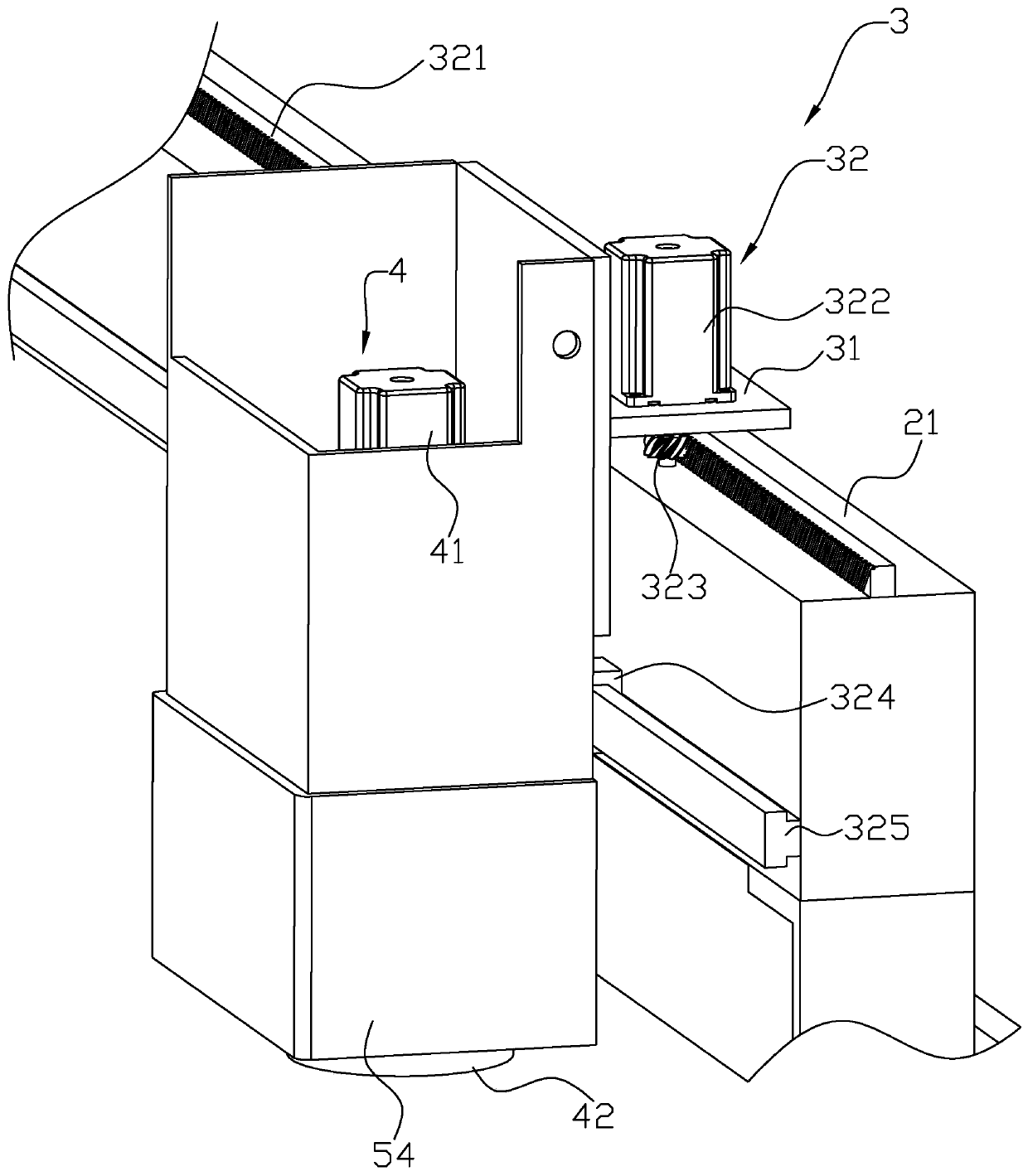

[0040] Embodiment: a kind of grinding machine for tempered glass production, such as figure 1 As shown, it includes a machine 1, an X-direction device 2, a Y-direction device 3, and a cooling device 5;

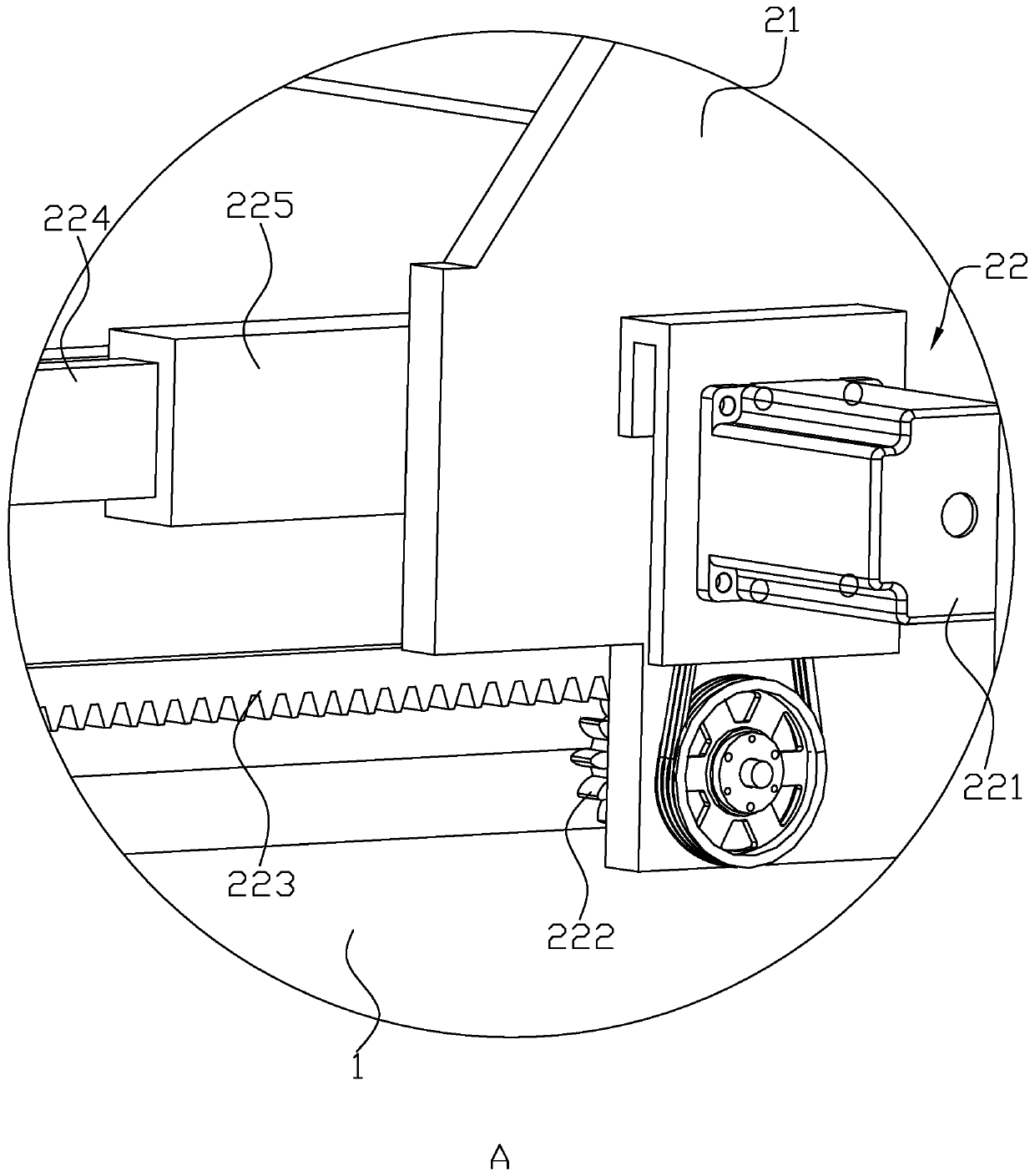

[0041] Such as figure 1 and figure 2 As shown, the X-direction device 2 includes a gantry 21 slidingly connected to the machine platform 1 along the X-axis direction and an X-direction driving mechanism for driving the movement of the gantry 21; Two sets of drive assemblies 22, each set of drive assemblies 22 include an X-direction asynchronous motor 221 horizontally arranged on one side of the gantry 21, an X-direction gear 222 installed on the output shaft of the X-direction asynchronous motor 221 through belt transmission, and a fixed connection to the machine. The X-direction rack 223 on one side of the table 1; the X-direction gear 222 and the X-direction rack 223 are meshed with each other; To the sleeve 225 , the two X-direction sleeves 225 are slidingly connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com