Electrolysis and side-filtration device for industrial circulating water and side-filtration method for industrial circulating water

A technology for industrial circulating water and circulating water, which is applied in water/sewage treatment, chemical instruments and methods, neutralized water/sewage treatment, etc., and can solve problems such as affecting equipment operation, a large number of precipitations, and poor results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

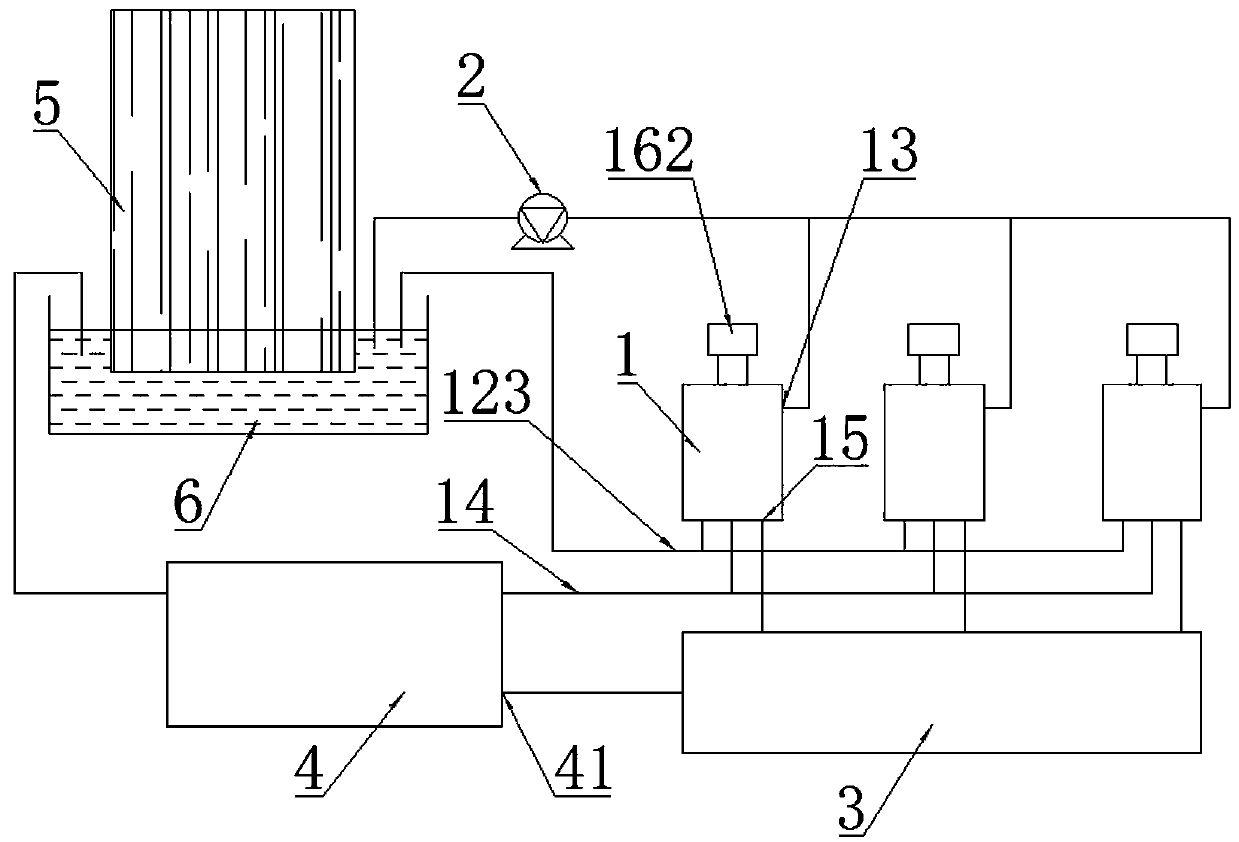

[0016] An industrial circulating water electrolysis bypass filter device includes an electrolytic tank 1, a circulation pump 2, a lime concentration tank 3, and a precipitation reaction tank 4. Such as figure 1 As shown, in this embodiment, the equipment that needs to filter circulating water is a cooling tower equipment, equipped with a cooling tower 5 and a circulating water pool 6 .

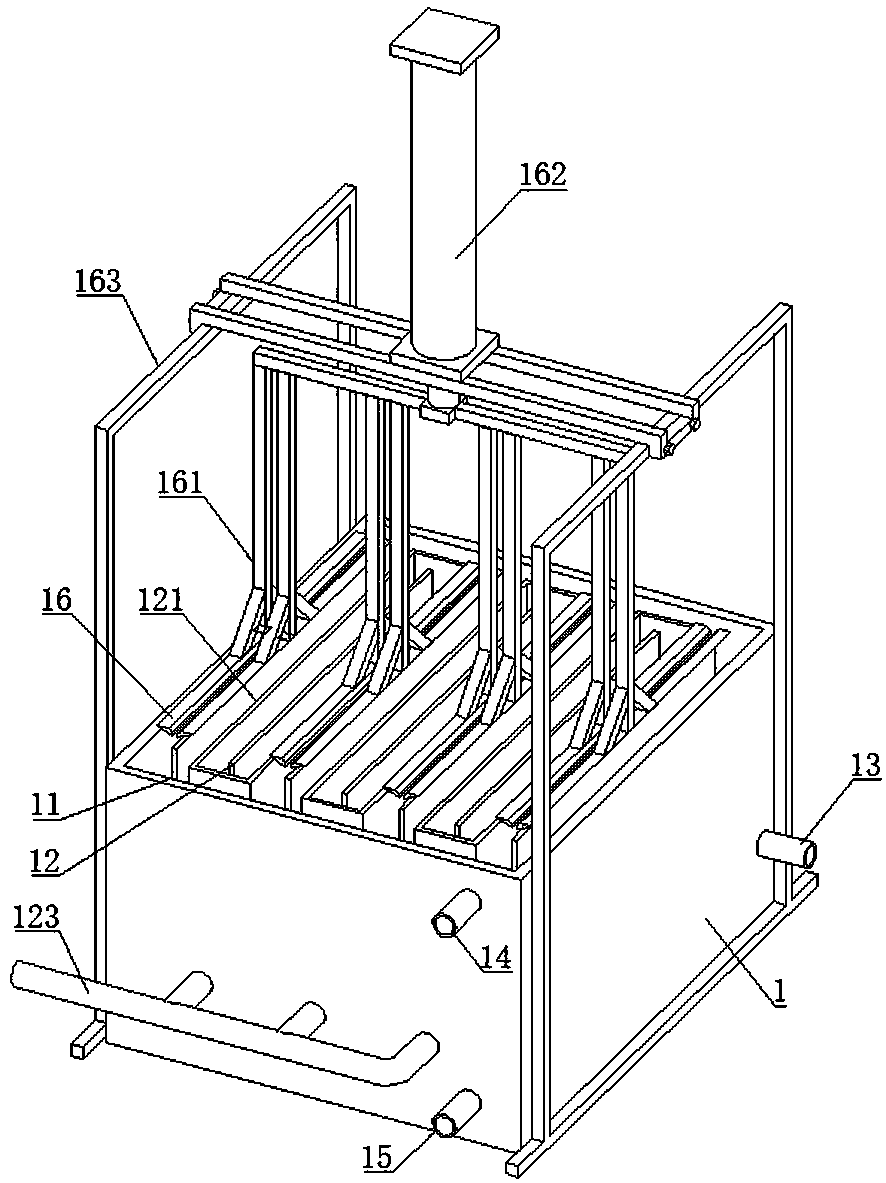

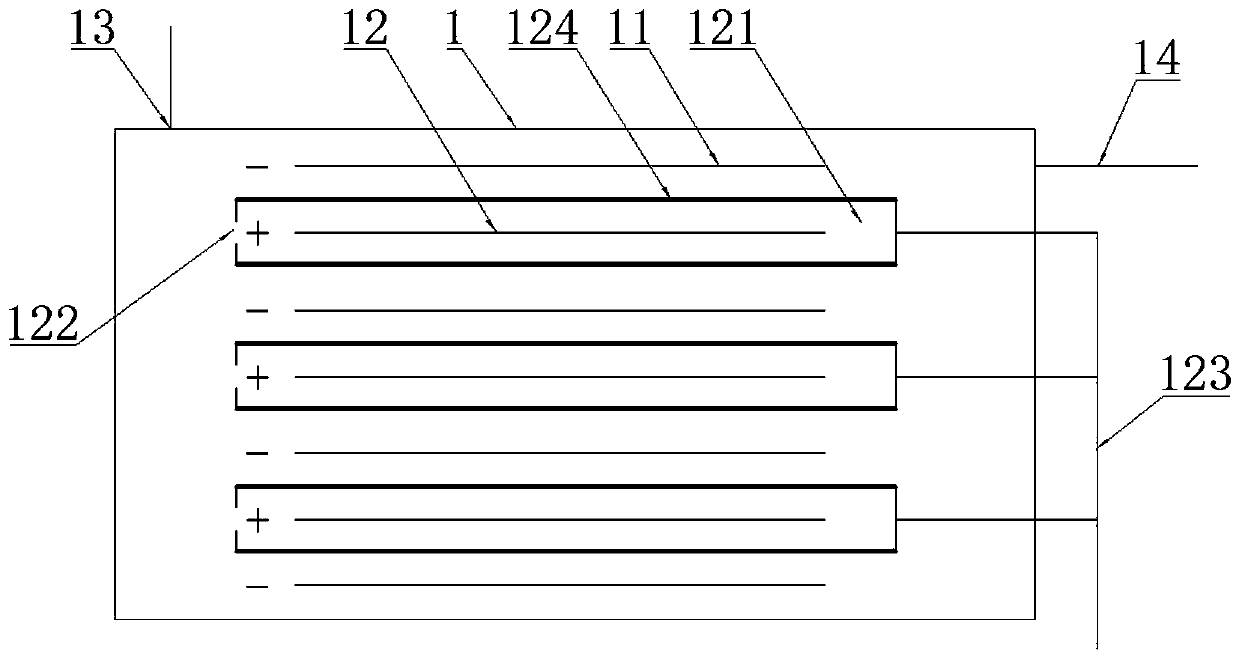

[0017] Such as figure 2 , 3 As shown, the cathode plate 11 and the anode plate 12 in the electrolytic cell 1 are arranged alternately, each anode plate is provided with a separate anode chamber 121, and the electrolytic cell 1 is provided with a water inlet 13 and a cathode outlet pipe 14 communicating with the circulating water pool 6, and the circulating water pool Circulation pump 2 is set between 6 and water inlet 13, and anode chamber 121 is provided with anode water inlet hole 122 and anode water outlet pipe 123, wherein, anode water inlet hole 122 communicates with the inside of elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com