Coiled electrochemical reactor, descaling method and heat exchanger

An electrochemical, winding technology, applied in the field of electrochemical reaction, can solve the problems of losing the anti-scaling effect, the diaphragm is easily damaged, and reducing the service life, and achieves the effect of simple descaling method, prolonging service life and reducing scale.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

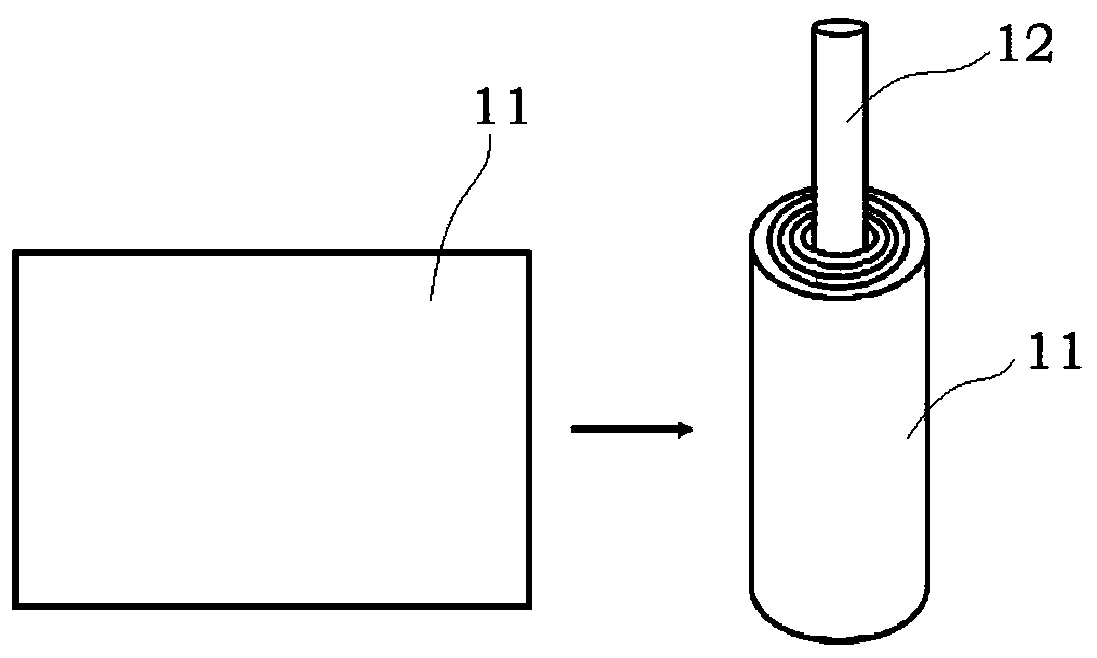

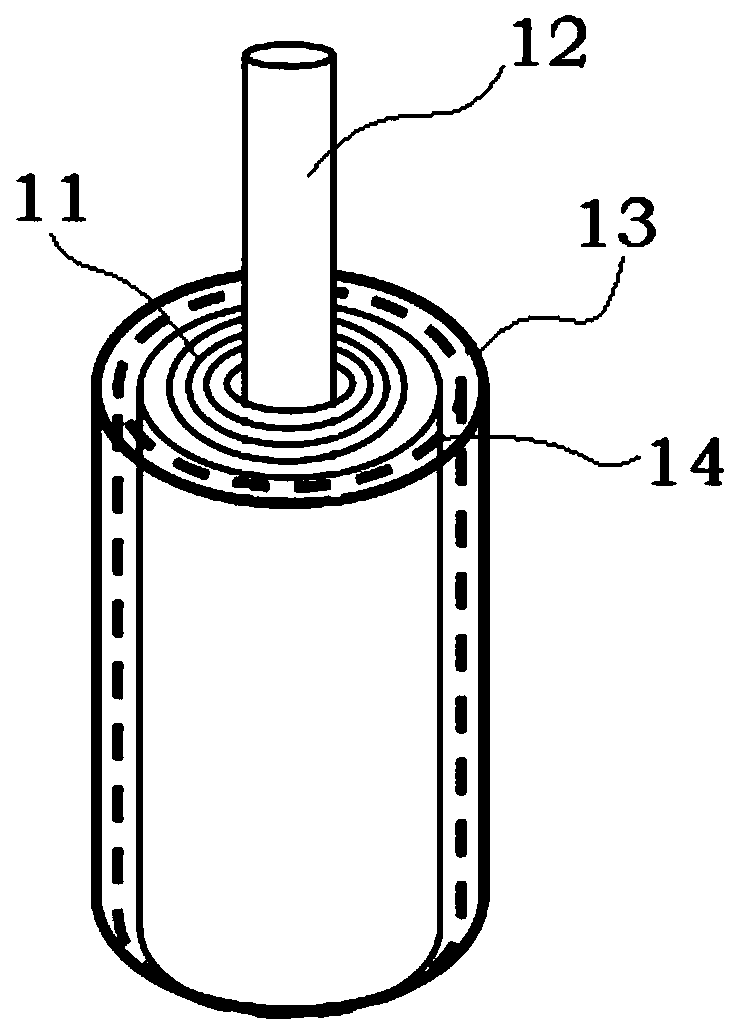

[0057] A coiled electrochemical reactor, such as figure 1 and figure 2 Shown includes a first anode 11, a second anode 12, a cathode 13 and an insulating layer 14; the first anode 11 is wound on the second anode 12, the cathode 13 is wound on the first anode 11, and the insulating layer 14 is located on the first Between the anode 11 and the cathode 13.

[0058] The material of the first anode 11 is a porous flexible conductive material, which can be carbon fiber, carbon felt, carbon cloth or titanium mesh with a coated surface, but is not limited to carbon fiber, carbon felt, carbon cloth or titanium with a coated surface. Wire mesh, the titanium wire mesh whose surface is coated is the prior art; the number of layers wound by the first anode 11 is set according to actual needs;

[0059] The second anode 12 is a rod-shaped or tubular anode, and the first anode 11 is radially wound on the second anode 12 along the axis of the second anode 12 to form a cylindrical anode with...

Embodiment 2

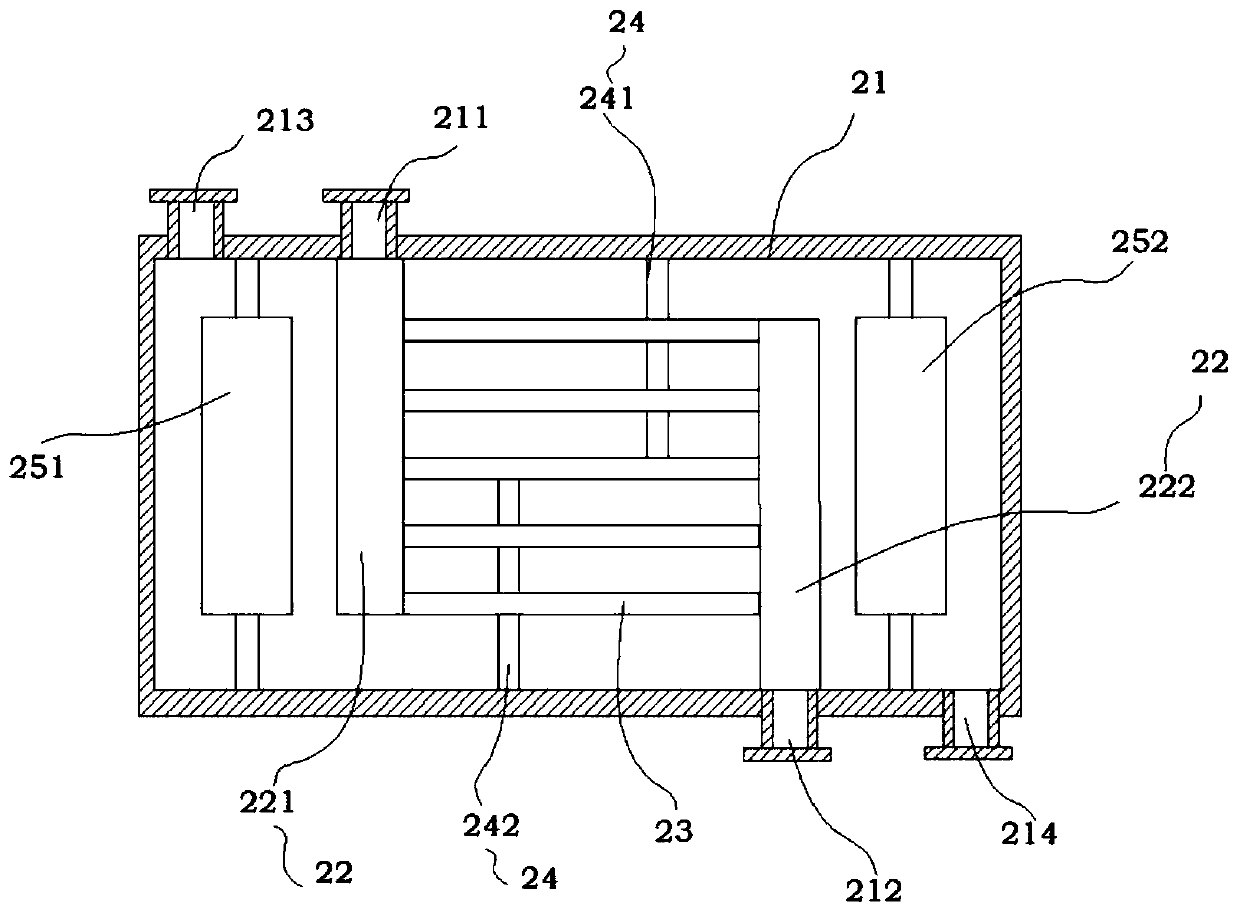

[0070] The water body is treated by the coiled electrochemical reactor in Example 1:

[0071] Bind the coiled electrochemical reactor with cable ties, then put the coiled electrochemical reactor into a hollow circular tube, the inner diameter of the circular tube is equal to or slightly larger than the outer diameter of the first anode , avoiding that the water body to be treated does not pass through the reaction system, the length of the round pipe is set according to the length of the second anode 12, the water body to be treated flows in from one end of the round pipe, and flows out from the other end of the round pipe, and the water flow and the coiled electrochemical reactor The contact time affects the removal efficiency of alkalinity in the water body. By controlling the control time with the coiled electrochemical reactor, the alkaline ions in the water body can be reduced or eliminated.

[0072] The influent alkalinity of the water to be treated is 2.0mmol / L, and whe...

Embodiment 3

[0074] The difference between this embodiment and Example 1 is that a plurality of coiled electrochemical reactors are set, each coiled electrochemical reactor is bound with cable ties, and then the coiled electrochemical reactors are placed into a circular tube whose inner diameter is equal to the outer diameter of the first anode 11, and a plurality of circular tubes are arranged in series, so that a plurality of coiled electrochemical reactors are arranged in series, and the number of coiled electrochemical reactors is set according to actual needs It is determined that the number of series in this embodiment is 3, and after the water body is treated by one of the coiled electrochemical reactors, it is in contact with the other coiled electrochemical reactor to improve the treatment effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com