Denitrification treatment method for industrial wastewater

A technology for industrial wastewater and treatment methods, which is applied in water treatment parameter control, biological water/sewage treatment, adsorption water/sewage treatment, etc. It can solve problems such as lack of carbon sources, high organic load of aerobic units, and increased operating costs. To achieve the effect of improving the biodegradability of wastewater, reducing inhibition and reducing organic load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

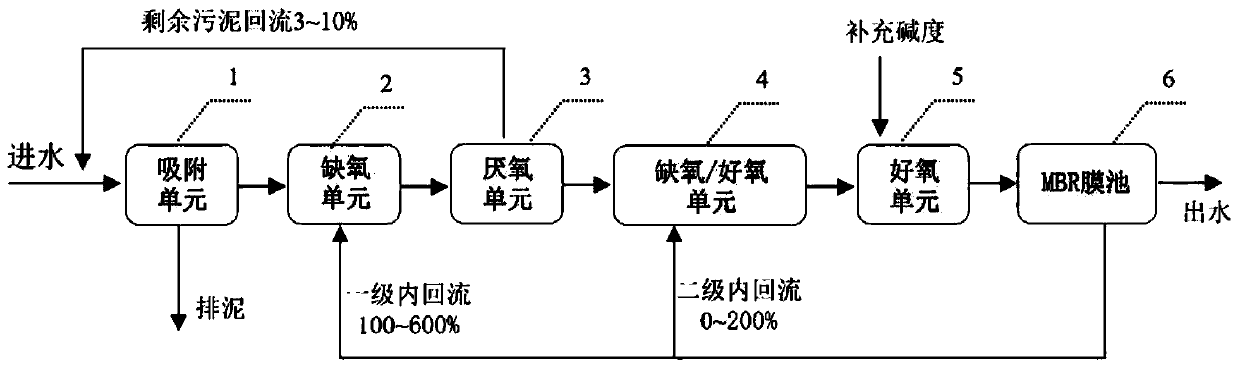

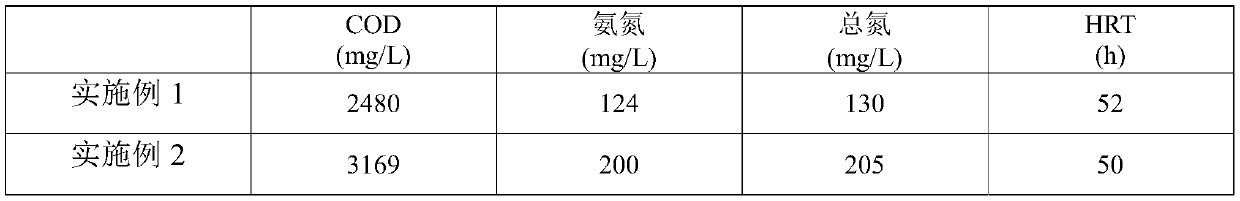

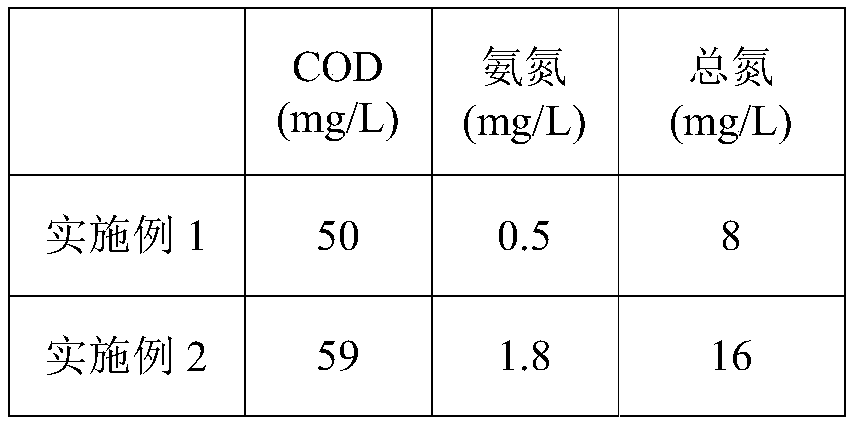

[0040] The composition of coking wastewater is shown in Table 1, with reference to the above-mentioned industrial wastewater denitrification treatment method: wherein, in step (1), the sludge age of the activated sludge is 18 hours, the HRT of the adsorption treatment is 2 hours, and the anaerobic unit The remaining sludge reflux ratio of reflux is 4%, and in step (2), the HRT of anaerobic denitrification treatment is 8 hours, and the reflux ratio 400% in one-level; In step (3), the HRT of hydrolytic acidification reaction is 10 hours; in step (4), the HRT of synchronous nitrification and denitrification reaction is 10 hours, and the secondary internal reflux ratio is 50%; in step (5), the total HRT of aerobic unit and membrane pool is 15~20 hours; and in steps (2), (3), (4) and (5), the sludge concentration is 6g / L, the pH is 7.0 to 7.3, and the temperature in steps (1) to (5) is 25°C.

Embodiment 2

[0042] The composition of coking wastewater is shown in Table 1, with reference to the above-mentioned industrial wastewater denitrification treatment method: wherein, in step (1), the sludge age of the activated sludge is 24 hours, the HRT of the adsorption treatment is 2 hours, and the anaerobic unit The remaining sludge reflux ratio of reflux is 6%, and in step (2), the HRT of anaerobic denitrification treatment is 10 hours, and the reflux ratio 600% in one-level; In step (3), the HRT of hydrolytic acidification reaction is 10 hours; in step (4), the HRT of synchronous nitrification and denitrification reaction is 10 hours, and the secondary internal reflux ratio is 50%; in step (5), the total HRT of aerobic unit and membrane pool is 20~25 hours; and in steps (2), (3), (4) and (5), the sludge concentration is 7g / L, the pH is 7.1 to 7.4, and the temperature in steps (1) to (5) is 25°C.

[0043] Table 1 Example 1 and Example 2 Influent parameters of coking wastewater

[0044...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com