Method for normal-temperature normal-pressure electro-catalysis wet-type oxidation treatment on cotton pulp black liquor

A technology for catalyzing wet oxidation and cotton pulp, which is applied in chemical instruments and methods, regeneration of lye, chemical/physical processes, etc., and can solve the problems that the treatment process and method are difficult to meet the standards, the equipment investment and maintenance costs are high, and the requirements are high. , to improve the biodegradability of wastewater, achieve discharge standards, and reduce the effect of COD value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

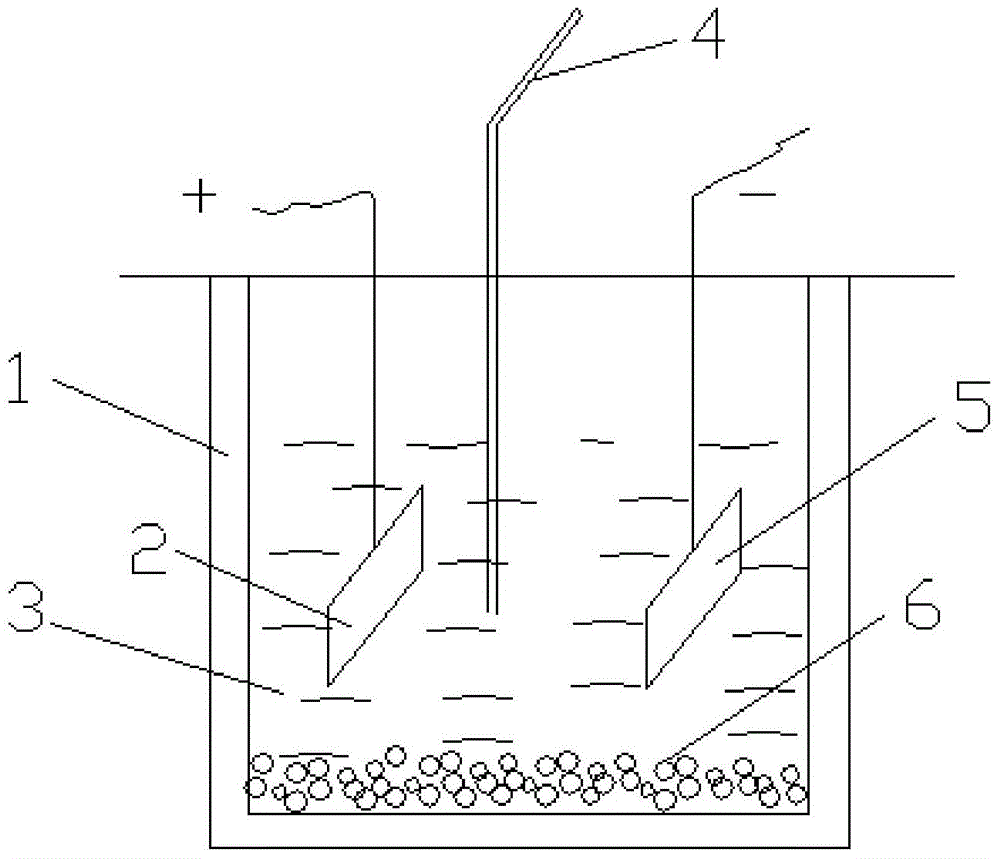

[0019] Electrolysis device and instructions for use:

[0020] Device: composed of reactor 1, anode plate 2, cotton pulp black liquor 3, air inlet pipe 4, cathode plate 5, metal oxide catalyst particles 6;

[0021] Operation: Adjust the cotton pulp black liquor 3 with industrial hydrochloric acid to make the pH to 5, in which the anode plate 2 and the cathode plate 5 are respectively connected to the positive and negative electrodes of the power supply through copper wires, and at the same time, a constant voltage of 15v is applied to the reactor 1. Add 20g / L of supported metal oxide composite catalyst particles 6, and disperse them at the bottom of the reactor, and continuously pass into the air pipe 4 for aeration, the aeration rate is 2.0L / min, the whole electrocatalysis process is at room temperature, Under normal pressure, the reaction time is 2h.

[0022] Electrolytic treatment:

[0023] The cotton pulp black liquor is treated with a separate electrolysis method, the pH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com