Cephalosporin antibiotic production wastewater treatment system and process

A wastewater treatment system and wastewater production technology, applied in the direction of biological water/sewage treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of reducing the COD index of wastewater, reduce the load of subsequent equipment, and improve the reliability of wastewater biochemical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] Preparation of composite flocculant

[0050] The composite flocculant used in the embodiment of the present invention is obtained by compounding carbon powder, iron powder, aluminum chloride, and polyaluminum chloride according to a mass ratio of 2:3:8:1. 0.2%.

[0051] Setup of iron-carbon micro-electrolytic cell

[0052] In the embodiment of the present invention, the iron-carbon micro-electrolytic cell is set as follows: in the iron-carbon micro-electrolytic cell I, the mass ratio of fillers to iron filings and coke is 3:2, and the pH is 3; in the iron-carbon micro-electrolytic cell II, the fillers are iron filings, The mass ratio of copper particles and coke is 3:0.5:2, and the pH is 4.

[0053] Preparation of coagulation sedimentation agent

[0054] The coagulation-sedimentation agent used in the embodiment of the present invention is obtained by compounding polyaluminum chloride and calcium oxide at a ratio of 4:1, and the addition amount of the coagulati...

Embodiment 1

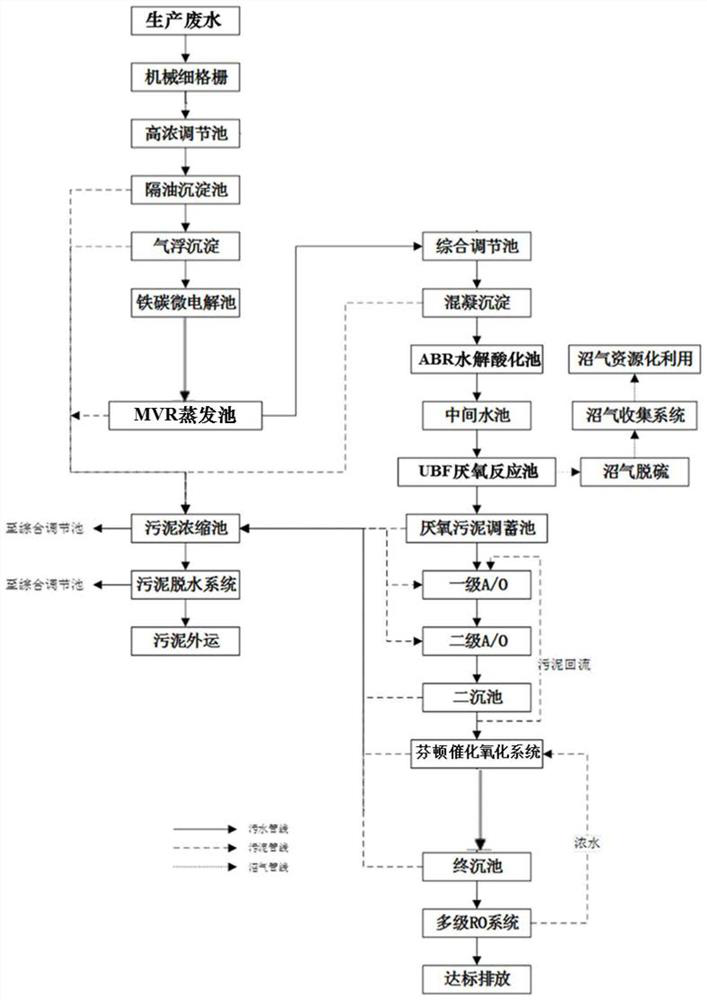

[0063] The pretreatment process of pharmaceutical production wastewater is: production wastewater - mechanical fine grid - high concentration adjustment tank - oil separation sedimentation tank - air flotation sedimentation tank - iron carbon micro electrolysis tank - MVR evaporation tank.

[0064] S1: The production wastewater is firstly filtered through mechanical fine grids, and the effluent flows into the high-concentration adjustment tank for homogeneous and even quantity adjustment;

[0065] S2: The effluent from the high-concentration adjustment tank enters the oil separation sedimentation tank to treat the organic solvent in the wastewater, and the effluent enters the air flotation sedimentation tank, and adds a composite flocculant to the air flotation sedimentation tank to remove suspended matter;

[0066] S3: The effluent from the air flotation sedimentation tank enters the iron-carbon micro-electrolysis cell to oxidize the chromophoric groups in the wastewater, and ...

Embodiment 2

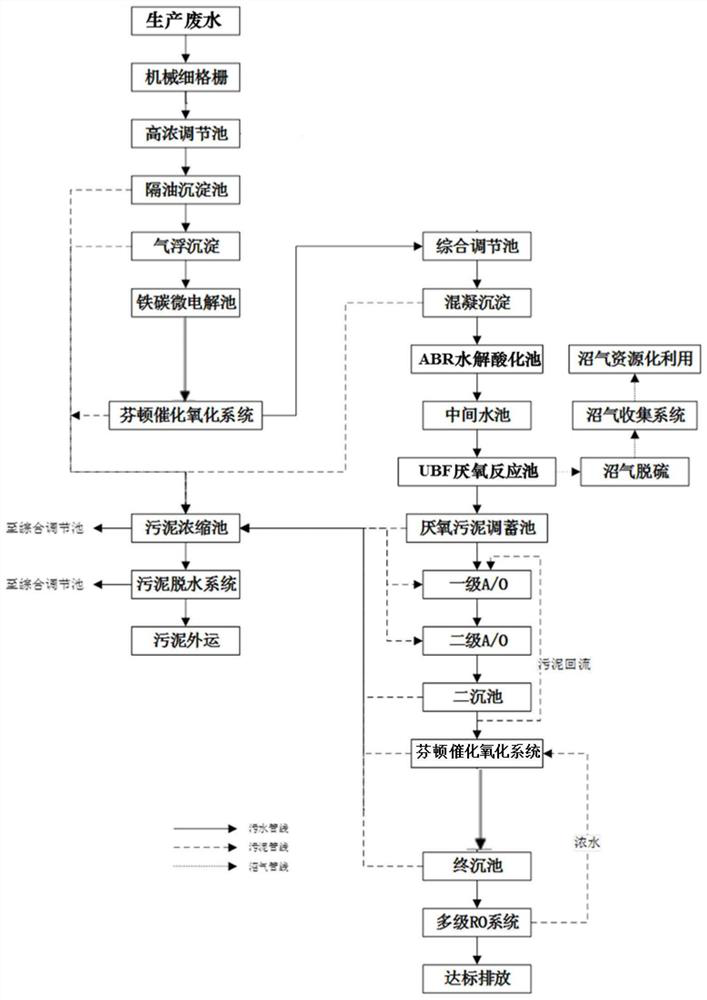

[0069] The pretreatment process of pharmaceutical production wastewater is as follows: production wastewater—mechanical fine grid—high concentration adjustment tank—grease separation sedimentation tank—air flotation sedimentation tank—iron-carbon micro electrolytic cell—Fenton catalytic oxidation system.

[0070] S1: The production wastewater is firstly filtered through mechanical fine grids, and the effluent flows into the high-concentration adjustment tank for homogeneous and even quantity adjustment;

[0071] S2: The effluent from the high-concentration adjustment tank enters the oil separation sedimentation tank to treat the organic solvent in the wastewater, and the effluent enters the air flotation sedimentation tank, and adds a composite flocculant to the air flotation sedimentation tank to remove suspended matter;

[0072] S3: The effluent from the air flotation sedimentation tank enters the iron-carbon micro-electrolysis cell to oxidize the chromophoric groups in the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com