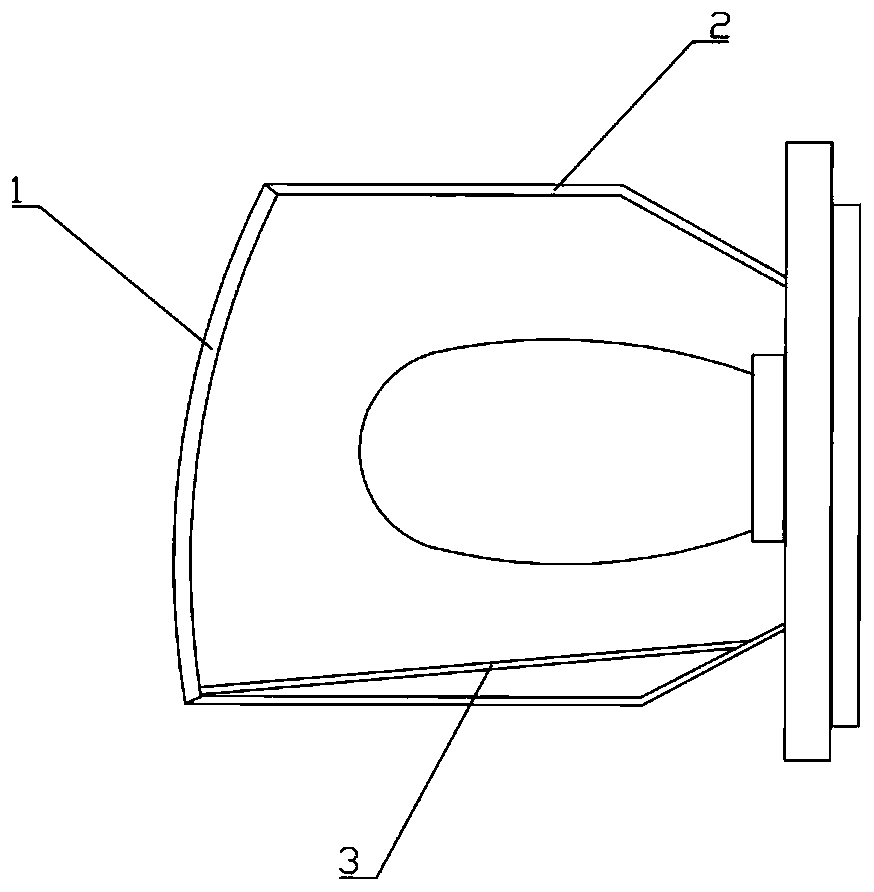

Automobile lamp shade with self cleaning function

A lampshade, self-cleaning technology, applied in the direction of headlights, motor vehicles, road vehicles, etc., can solve the problems of fogging, contamination, adsorption of organic volatiles in the lampshade, etc., to prevent fogging and not easily contaminated with dirt. , the effect of decreased adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

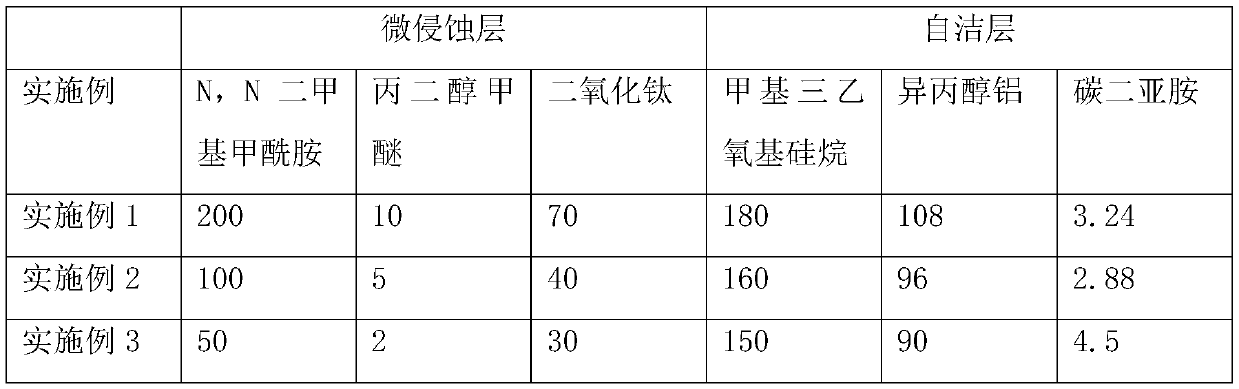

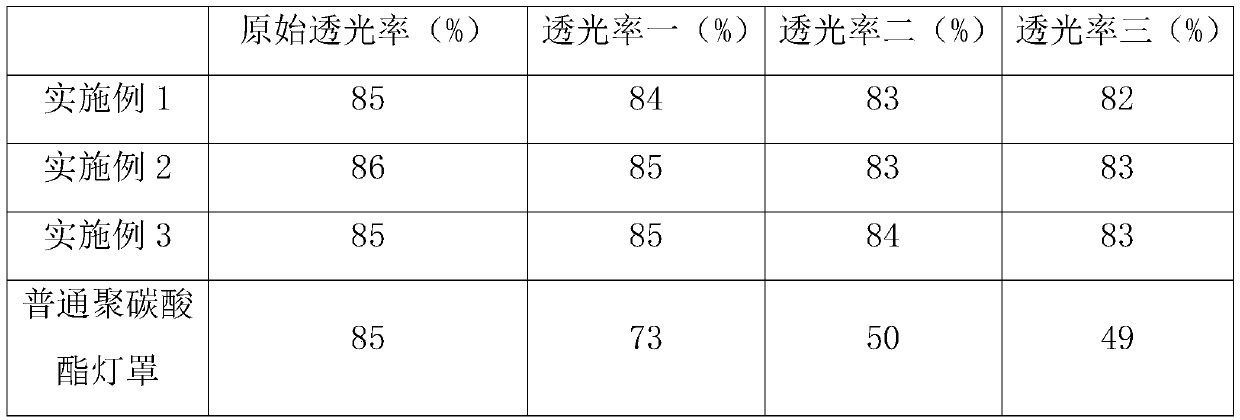

Embodiment 1

[0035] In this embodiment, the raw materials are weighed according to the ratio of Example 1 in Table 1, and the preparation steps are as follows:

[0036] Titanium dioxide pretreatment: first wash the titanium dioxide with a particle size of about 20nm with an ethanol solution, then remove the ethanol with water, dry it and put it in a low-temperature plasma device with oxygen as the working gas, a pressure of 1Pa, and a power of 100W for 1min. Then take it out for use;

[0037] (1) Pretreatment: Clean the surface of the photometric mirror with 35wt% ethanol solution, then clean it with clean water, place it in an oven, preheat the photometric mirror to 30°C, and set it aside;

[0038](2) Preparation of micro-erosion layer: add N,N dimethylformamide into the ethanol solution, stir well and prepare N,N dimethylformamide-ethanol mixed solution, wherein N,N dimethylformamide The concentration is 11wt%, then add propylene glycol methyl ether, mix well and then add the pretreated...

Embodiment 2

[0042] In this embodiment, the raw materials are weighed according to the ratio of Example 2 in Table 1, and the preparation steps are as follows:

[0043] Titanium dioxide pretreatment: first wash the titanium dioxide with a particle size of about 25nm with an ethanol solution, then remove the ethanol with water, dry it and put it in a low-temperature plasma device with oxygen as the working gas, a pressure of 1Pa, and a power of 100W for 2 minutes. Then take it out for use;

[0044] (1) Pretreatment: Clean the surface of the photometric mirror with 35wt% ethanol solution, then clean it with clean water, place it in an oven, preheat the photometric mirror to 33°C, and set it aside;

[0045] (2) Preparation of micro-erosion layer: add N,N dimethylformamide into the ethanol solution, stir well and prepare N,N dimethylformamide-ethanol mixed solution, wherein N,N dimethylformamide The concentration is 10wt%, then add propylene glycol methyl ether, mix well and then add the pret...

Embodiment 3

[0049] In this embodiment, the raw materials are weighed according to the ratio of Example 3 in Table 1, and the preparation steps are as follows:

[0050] Titanium dioxide pretreatment: first wash the titanium dioxide with a particle size of about 20nm with an ethanol solution, then remove the ethanol with water, dry it and put it in a low-temperature plasma device with oxygen as the working gas, a pressure of 1Pa, and a power of 100W for 1min. Then take it out for use;

[0051] (1) Pretreatment: Clean the surface of the photometric mirror with 35wt% ethanol solution, then clean it with clean water, place it in an oven, preheat the photometric mirror to 35°C, and set it aside;

[0052] (2) Preparation of micro-erosion layer: add N,N dimethylformamide into the ethanol solution, stir well and prepare N,N dimethylformamide-ethanol mixed solution, wherein N,N dimethylformamide The concentration is 9wt%, then add propylene glycol methyl ether, mix well and then add the pretreated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com