System and method for natural animal and plant extraction

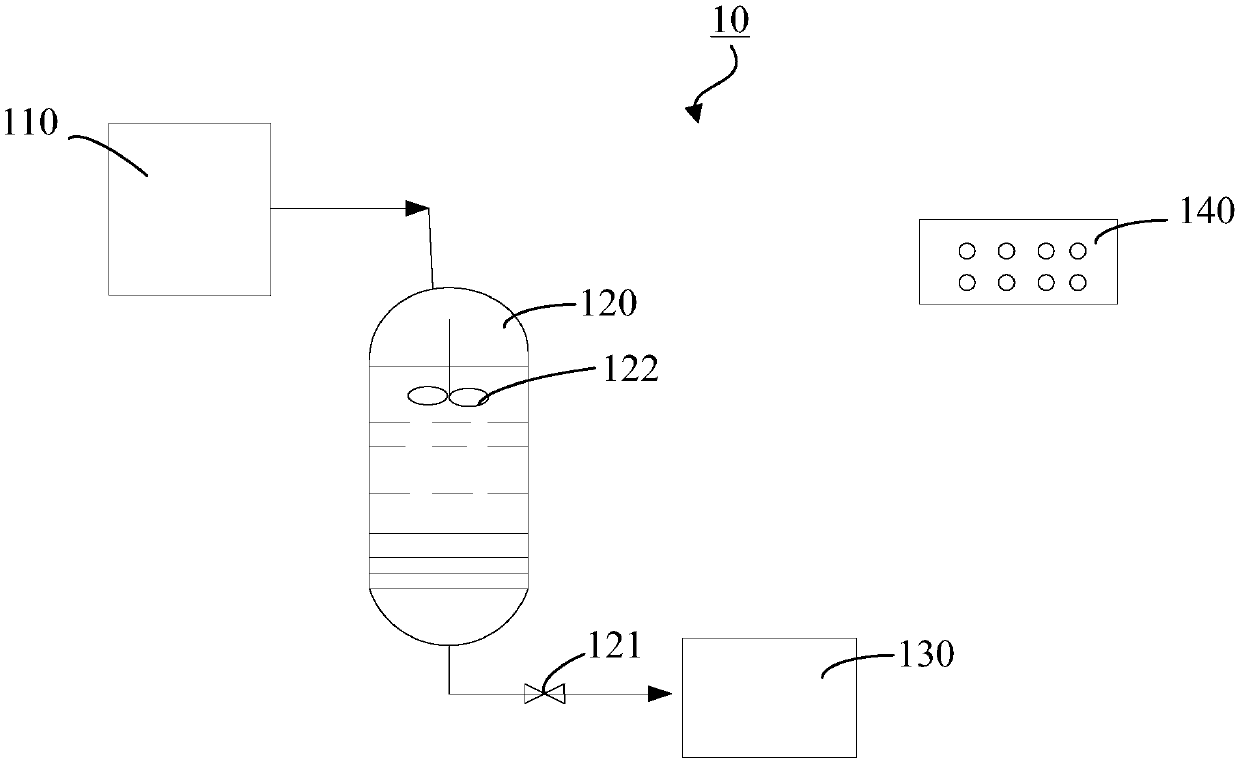

An extraction system, animal and plant technology, applied in the field of natural animal and plant extraction, can solve the problems of inability to realize comprehensive and efficient continuous extraction of natural animals and plants, unfavorable large-scale industrial application, and affecting the safety of extracted components, so as to achieve automatic control, Reduced number of operators and high safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

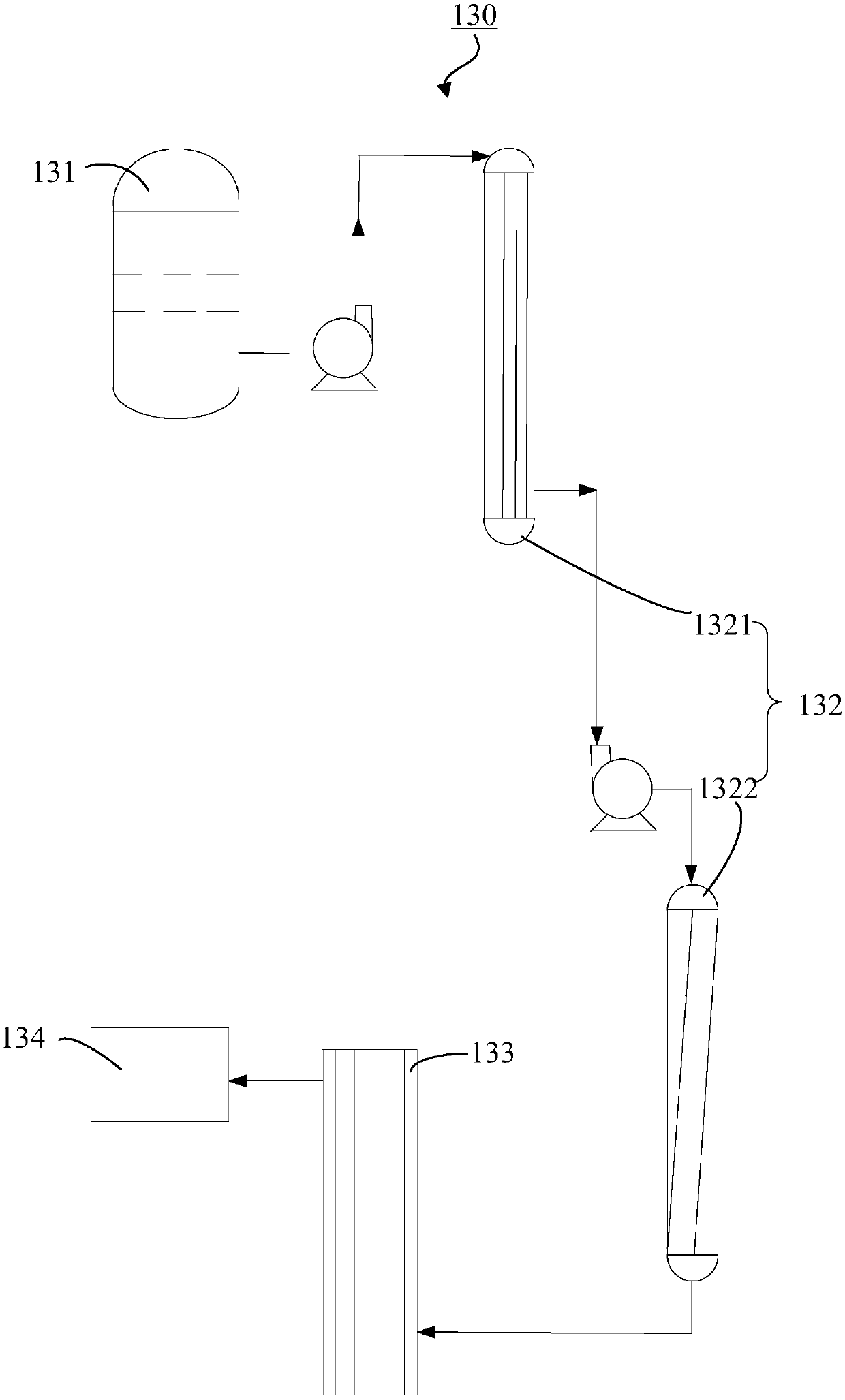

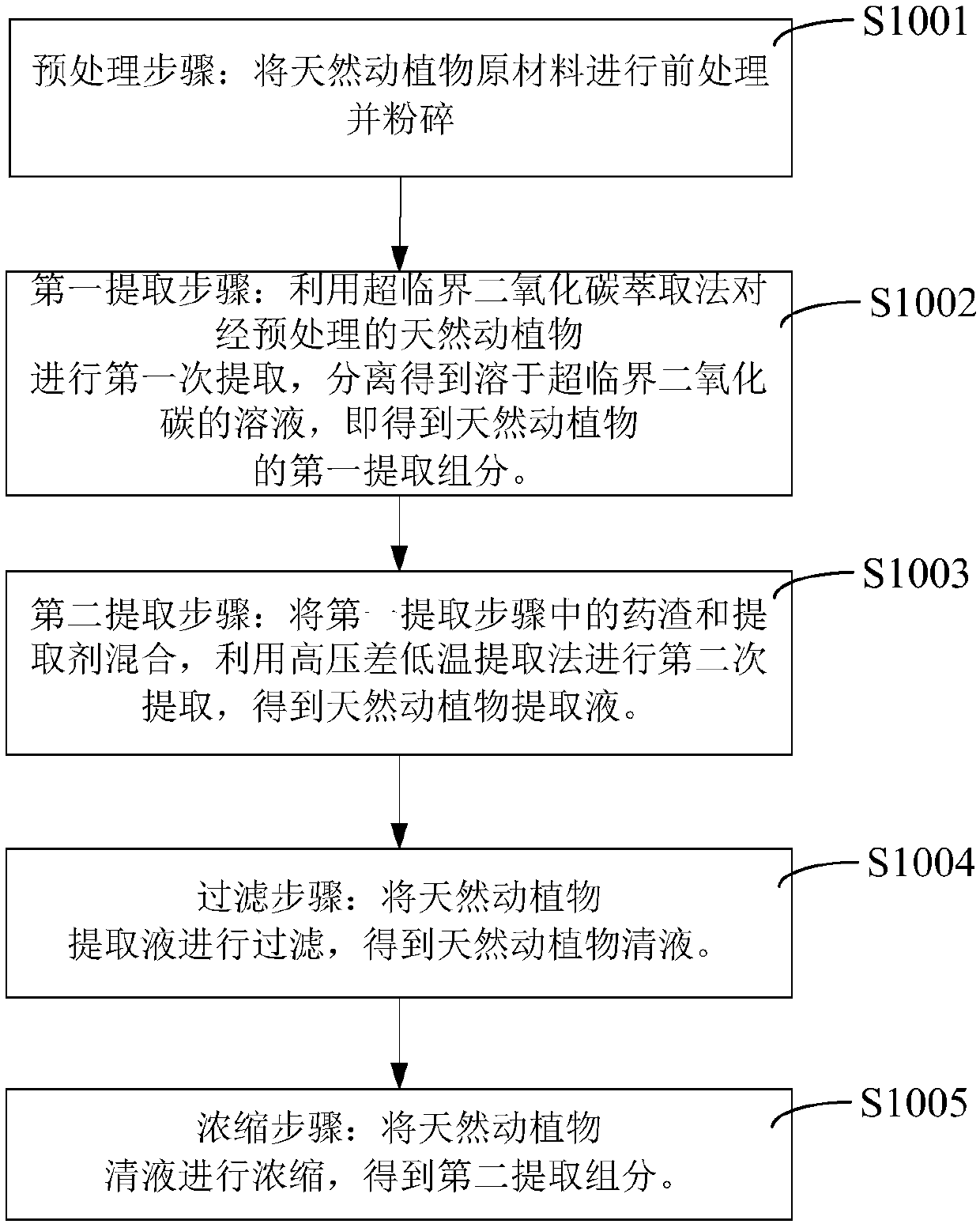

Method used

Image

Examples

Embodiment 1

[0087] Natural plants and animals to be extracted: roses

[0088] (1) Preprocessing steps

[0089] Carefully observe the raw materials of roses, remove obvious impurities on the surface, use a universal pulverizer to crush the materials, and sieve through 20 meshes.

[0090] (2) The first extraction step

[0091] Put 10kg of crushed rose raw material into supercritical CO 2 In the extraction kettle, turn on the CO while starting the refrigeration device 2 Gas tank, liquid CO 2 Pump it into the extraction kettle under high pressure, keep the flow rate at 22L / h, at the extraction temperature of about 35°C, and the extraction pressure at about 25Mpa, after 2.5 hours of circular extraction, the extraction of the weakly water-soluble components of rose can be completed and collected in the separation kettle Yellow clear transparent liquid, stored in a bottle to obtain the first extract component of Example 1, the oil yield of the first extract component (fat-soluble component o...

Embodiment 2

[0099] Natural plants and animals to be extracted: Ganoderma lucidum

[0100] (1) Preprocessing steps

[0101] Carefully observe the raw materials of Ganoderma lucidum, remove obvious impurities on the surface, use a universal grinder to crush the materials, and sieve them to 20 mesh.

[0102] (2) The first extraction step

[0103] Put 20kg of crushed Ganoderma lucidum raw material into supercritical CO 2 In the extraction kettle, turn on the CO while starting the refrigeration device 2 Gas tank, liquid CO 2 Pump it into the extraction kettle under high pressure, keep its flow rate at 20L / h, at an extraction temperature of about 35°C, and an extraction pressure of about 26Mpa, after 3 hours of extraction, the extraction of the weakly water-soluble components of Ganoderma lucidum can be completed, and a yellow oil is collected in the separation kettle Paste, bottled storage can be the first extraction component of Example 2, the oil yield of the first extraction component (...

Embodiment 3

[0111] Natural plants and animals to be extracted: tangerine peel

[0112] (1) Preprocessing steps

[0113] Carefully observe the raw material of tangerine peel, remove obvious impurities on the surface, use a universal grinder to crush the material, and sieve 60 mesh.

[0114] (2) The first extraction step

[0115] Pack 15kg of dried tangerine peel raw material after crushing into supercritical CO 2 In the extraction kettle, turn on the CO while starting the refrigeration device 2 Gas tank, liquid CO 2 Pump it into the extraction kettle under high pressure, keep its flow rate at 20L / h, at an extraction temperature of about 20°C, and an extraction pressure of about 23Mpa, after 2.5 hours of extraction, the extraction of the weakly water-soluble components of cinnamon can be completed, and yellow The oily paste can be stored in a bottle to obtain the first extraction component of Example 3, and the oil yield of the first extraction component (fat-soluble component of tanger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com