Mercury-free dry battery

A mercury dry battery and cell technology, applied in the field of dry batteries, can solve problems such as improper operation, human injury to production staff, pollution, etc., and achieve the effects of safety guarantee, reduction of uneven corrosion, and reduction of pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

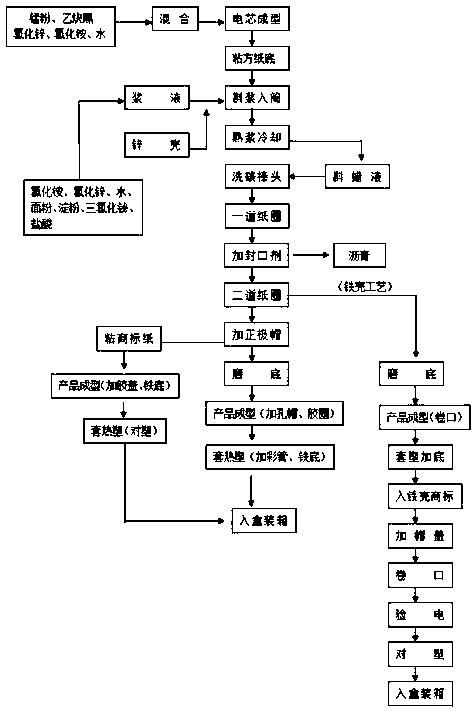

Image

Examples

Embodiment 1

[0021] A mercury-free dry battery, the raw material slurry is as follows by weight percentage: 7.2-7.6% of zinc chloride, 15-17% of ammonium chloride, 25-28% of flour and starch, 0.04-0.07% of polyacrylamide, 0.02-0.03% of hydrochloric acid %, bismuth trichloride 0.03-0.08%.

[0022] Specifically, the raw material slurry of the mercury-free dry battery also includes deionized water.

[0023] The present invention also provides a production process of a mercury-free dry battery, which includes the following steps: S1, cell production: fully mix and stir manganese powder, acetylene black, zinc chloride, ammonium chloride and water, and use a molding machine to make the cell Forming process, and then paste square paper on the surface; in S1, first place a layer of insulating pad on the bottom of the zinc shell, and fix the battery cell in the middle of the zinc shell;

[0024] S2. Slurry production: Zinc chloride 7.2-7.6%, ammonium chloride 15-17%, flour and starch 25-28%, polya...

Embodiment 2

[0028] A mercury-free dry battery, the raw material slurry is as follows by weight percentage: 7.2-7.6% of zinc chloride, 15-17% of ammonium chloride, 25-28% of flour and starch, 0.04-0.07% of polyacrylamide, 0.02-0.03% of hydrochloric acid %, bismuth trichloride 0.03-0.08%.

[0029] Specifically, the raw material slurry of the mercury-free dry battery also includes deionized water.

[0030] The present invention also provides a production process of a mercury-free dry battery, which includes the following steps: S1, cell production: fully mix and stir manganese powder, acetylene black, zinc chloride, ammonium chloride and water, and use a molding machine to make the cell Forming process, and then paste square paper on the surface; in S1, first place a layer of insulating pad on the bottom of the zinc shell, and fix the battery cell in the middle of the zinc shell;

[0031] S2. Slurry production: Zinc chloride 7.2-7.6%, ammonium chloride 15-17%, flour and starch 25-28%, polya...

Embodiment 3

[0035] A mercury-free dry battery, the raw material slurry is as follows by weight percentage: 7.2-7.6% of zinc chloride, 15-17% of ammonium chloride, 25-28% of flour and starch, 0.04-0.07% of polyacrylamide, 0.02-0.03% of hydrochloric acid %, bismuth trichloride 0.03-0.08%.

[0036] Specifically, the raw material slurry of the mercury-free dry battery also includes deionized water.

[0037] The present invention also provides a production process of a mercury-free dry battery, which includes the following steps: S1, cell production: fully mix and stir manganese powder, acetylene black, zinc chloride, ammonium chloride and water, and use a molding machine to make the cell Forming process, and then paste square paper on the surface; in S1, first place a layer of insulating pad on the bottom of the zinc shell, and fix the battery cell in the middle of the zinc shell;

[0038] S2. Slurry production: Zinc chloride 7.2-7.6%, ammonium chloride 15-17%, flour and starch 25-28%, polya...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com