A kind of preparation method of nano titanium material for anticorrosion

A nano-titanium and solvent technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of excessive particle size, low bulk density, and low purity of nano-titanium powder. Good stability, good wetting and adsorption properties, good anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

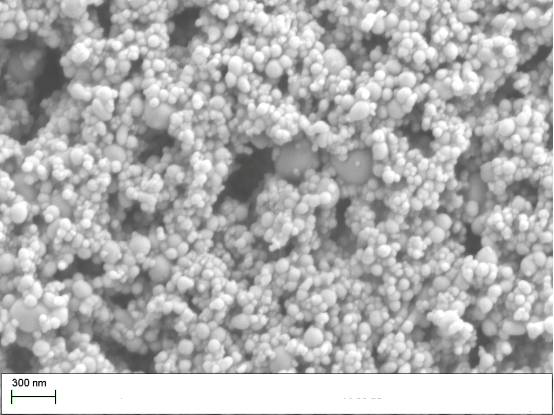

[0047] The preparation principle of the present invention is: after adding nano-scale titanium powder into a dispersant, it is highly dispersed in an organic solvent. The organic solvent matches the aluminum film of the lithium battery, and the product performance can reach the imported level, realizing import substitution.

[0048] Through the preparation method of the present invention, in step S1, by mixing and stirring, the nano-titanium powder can be fully dispersed into the solvent under the action of the dispersant; by standing still, the effect of the dispersant on the nano-titanium powder can be further promoted and strengthened. Adsorption and infiltration, so as to better promote the stable dispersion of nano-titanium powder in the solvent.

[0049] In step S1, although the adsorption and infiltration of the dispersant to the nano-titanium powder are promoted and strengthened after standing still, problems such as stratification will still occur, and it is necessary ...

Embodiment 1

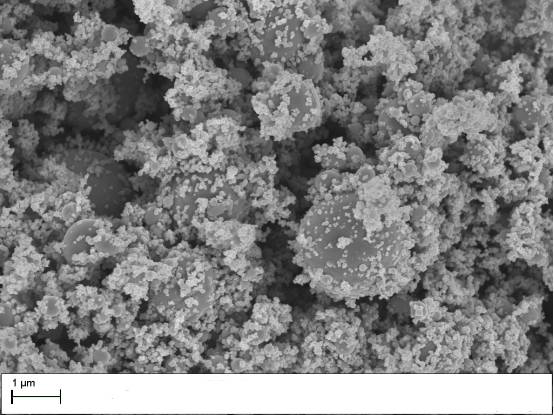

[0088] S1: Nano-titanium powder (prepared by electric explosion method, purity > 98%, the nano-titanium powder used contains particles above 1um), dispersant polyvinylpyrrolidone (abbreviation: pvp), and absolute ethanol at 10:1: 15 parts by weight were mixed, stirred with a mixer for 2 hours, and then left to stand for 24 hours;

[0089] S2: Stir fully with a mixer, and then ultrasonically perform ultrasonication for 30 minutes, and the ultrasonic temperature should not exceed 40°C;

[0090] S3: Centrifuge with a centrifuge, the speed of the centrifuge is 1000 rpm, the centrifugation time is 10 minutes, and the supernatant is taken after centrifugation;

[0091] S4: Centrifuge the supernatant liquid with a centrifuge, the centrifuge speed is 4000 rpm, and the centrifugation time is 30 minutes, and the bottom nano titanium powder is taken after centrifugation;

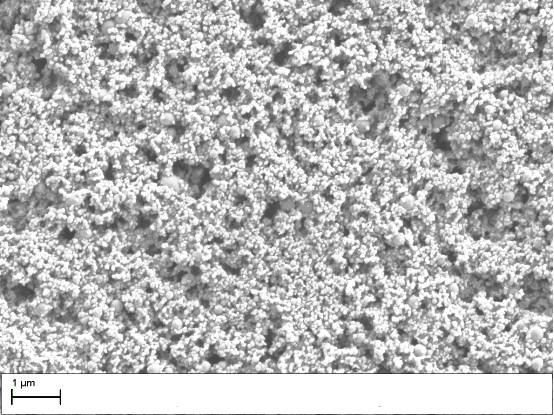

[0092] S5: Disperse the bottom nano-titanium powder in the solvent N-methylpyrrolidone (abbreviation: NMP) and stir...

Embodiment 2

[0095] S1: Mix nano-titanium powder (prepared by electric explosion method, purity > 98%, the used nano-titanium powder contains particles above 1um), dispersant polyvinyl alcohol, and acetone in a weight ratio of 99:1:50, Stir with a mixer for 3 hours, then let stand for 18 hours;

[0096] S2: Thoroughly stir with a mixer, and then use ultrasonic waves for 40 minutes, and the ultrasonic temperature is 30°C;

[0097] S3: Centrifuge with a centrifuge, the speed of the centrifuge is 1200 rpm, the centrifugation time is 9 minutes, and the supernatant is taken after centrifugation;

[0098] S4: Centrifuge the supernatant liquid with a centrifuge, the centrifuge speed is 5000 rpm, and the centrifugation time is 15 minutes, and the bottom nano titanium powder is taken after centrifugation;

[0099] S5: Disperse the bottom nano-titanium powder in the solvent N-methylpyrrolidone (abbreviation: NMP) and stir it with a mixer. The weight ratio of the bottom nano-titanium powder to N-met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com