Method for removing or reducing surface granules in oxide film and special-purpose polishing rod

A technology of oxide thin films and surface particles, which is applied in the usage of superconductor elements, the manufacture/processing of superconductor devices, and the manufacture of cables/conductors. Simple, low cost, and the effect of maintaining the performance of thin film samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

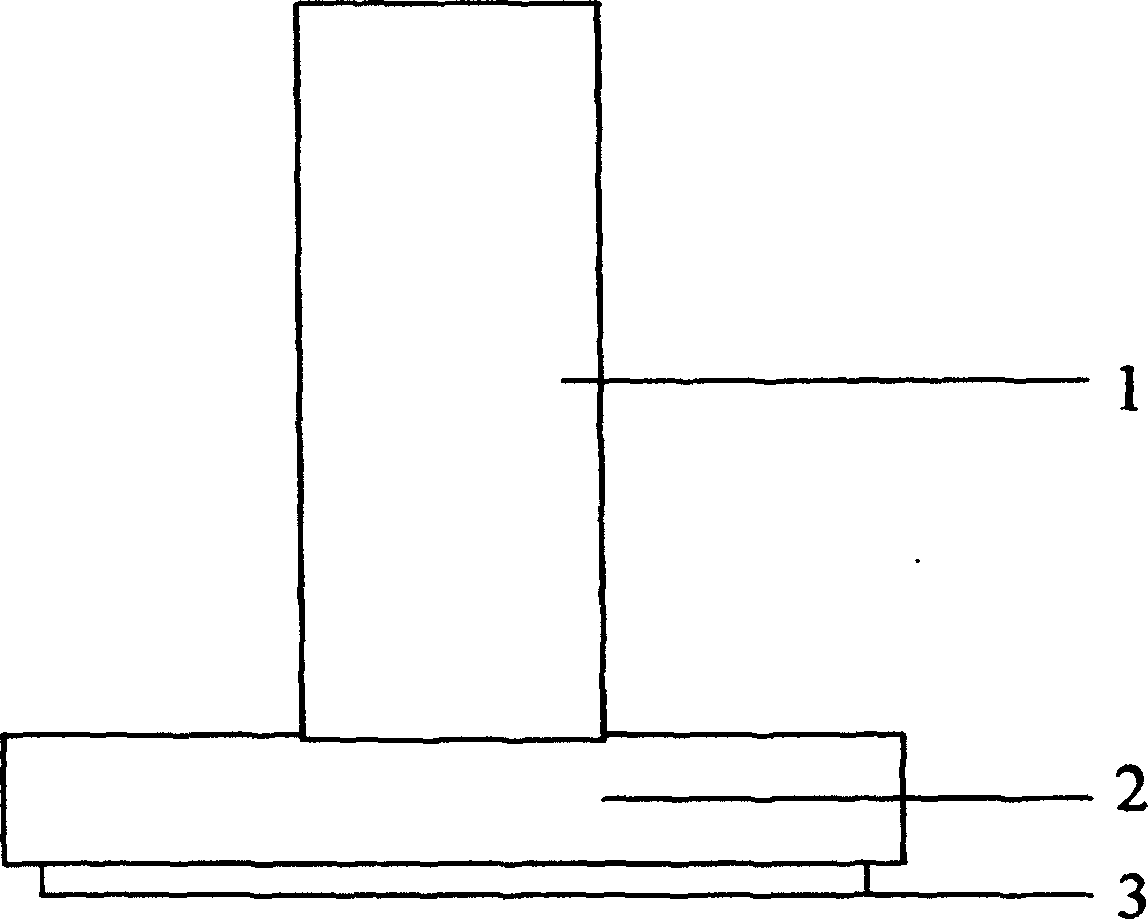

[0028] according to figure 1 Make a special polishing rod of the present invention, this polishing rod comprises a polishing rod handle 1 made of wood, a polishing rod base 2 made of rubber, the polishing surface of its polishing rod base 2 is smooth and smooth, and the polishing rod base 2 is fixed on The end of the handle 1 of the polishing rod, the base 2 is vertically fixed on the end of the handle 1, and the bottom surface of the base 2 is a polishing surface.

Embodiment 2

[0030] according to figure 1 Make a special polishing rod of the present invention, this polishing rod comprises a polishing rod handle 1 made of plastics, a polishing rod base 2 made of polytetrafluoroethylene, the polishing surface 5 of its polishing rod base 2 is smooth and smooth, and the polishing rod The base 2 is fixed on the end of the handle 1 of the polishing rod.

Embodiment 3

[0032] Put a piece of 3mm×10mm YBa 2 Cu 3 o 7-δ Large particle elimination in high temperature superconducting thin films.

[0033] What used in this embodiment is a piece of YBa prepared by pulsed laser deposition method of 3mm × 10mm 2 Cu 3 o 7-δ The high temperature superconducting thin film sample is the substrate 3 . The surface of the sample is rough and the particles are as large as image 3 shown. In the first step, the film sample was ultrasonically cleaned with alcohol for 10 minutes to ensure the surface of the film sample was clean. The second step is to ultrasonically clean the polishing rod with acetone for 10 minutes, and then ultrasonically clean it with alcohol for 10 minutes. The third step is to vertically press the polishing surface of the base of the polishing rod on the surface of the film substrate 3 to ensure that the polishing surface of the base of the polishing rod is in close and uniform contact with the surface of the film, and then quickly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com