Construction method of model-building concrete between fender piles of subway station

A technology for subway stations and construction methods, applied in excavation, construction, infrastructure engineering, etc., can solve problems affecting the quality of waterproof layer laying, affecting the construction progress of the main body, and affecting the compactness of concrete, so as to achieve controllable appearance quality and reduce material Cost, reduce the effect of plastering process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

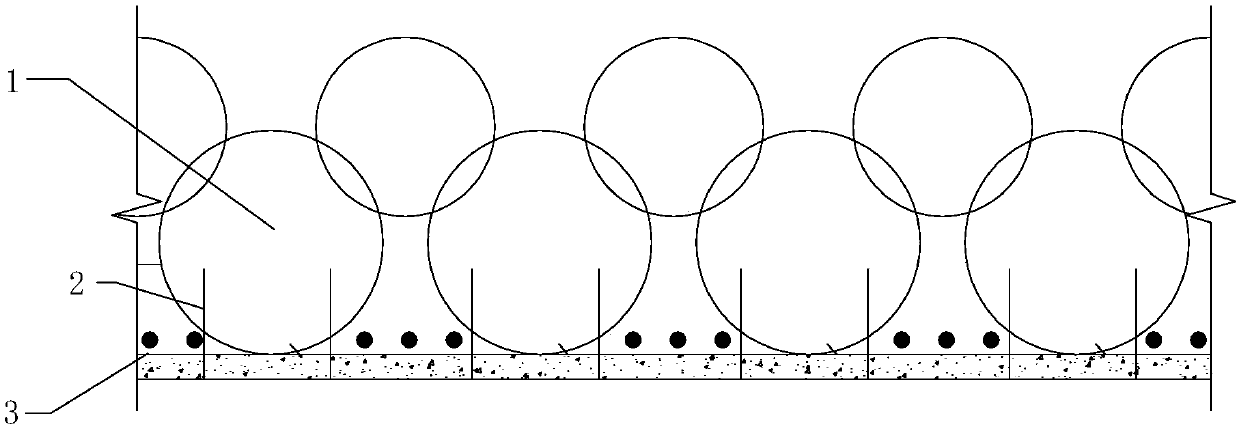

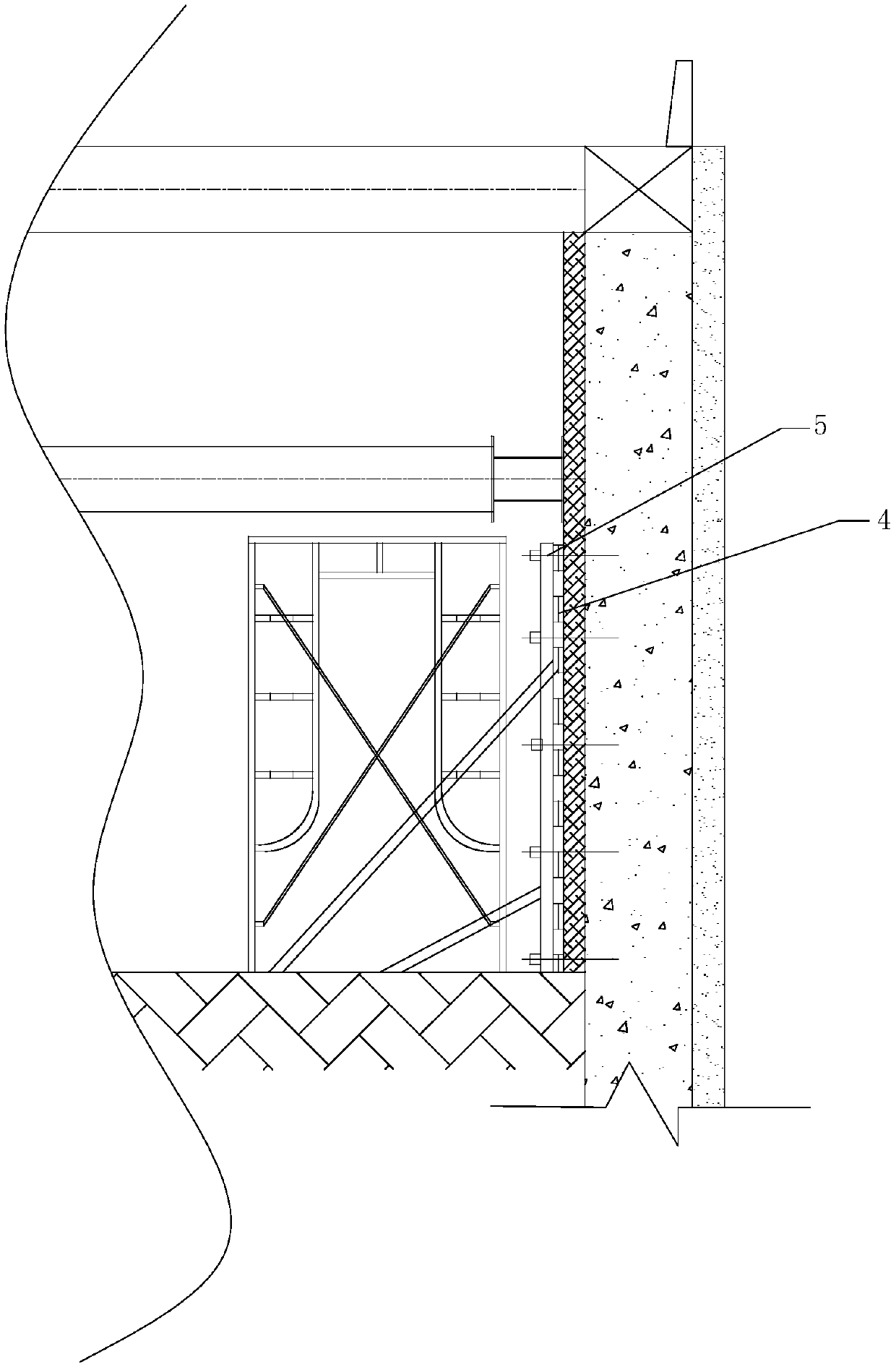

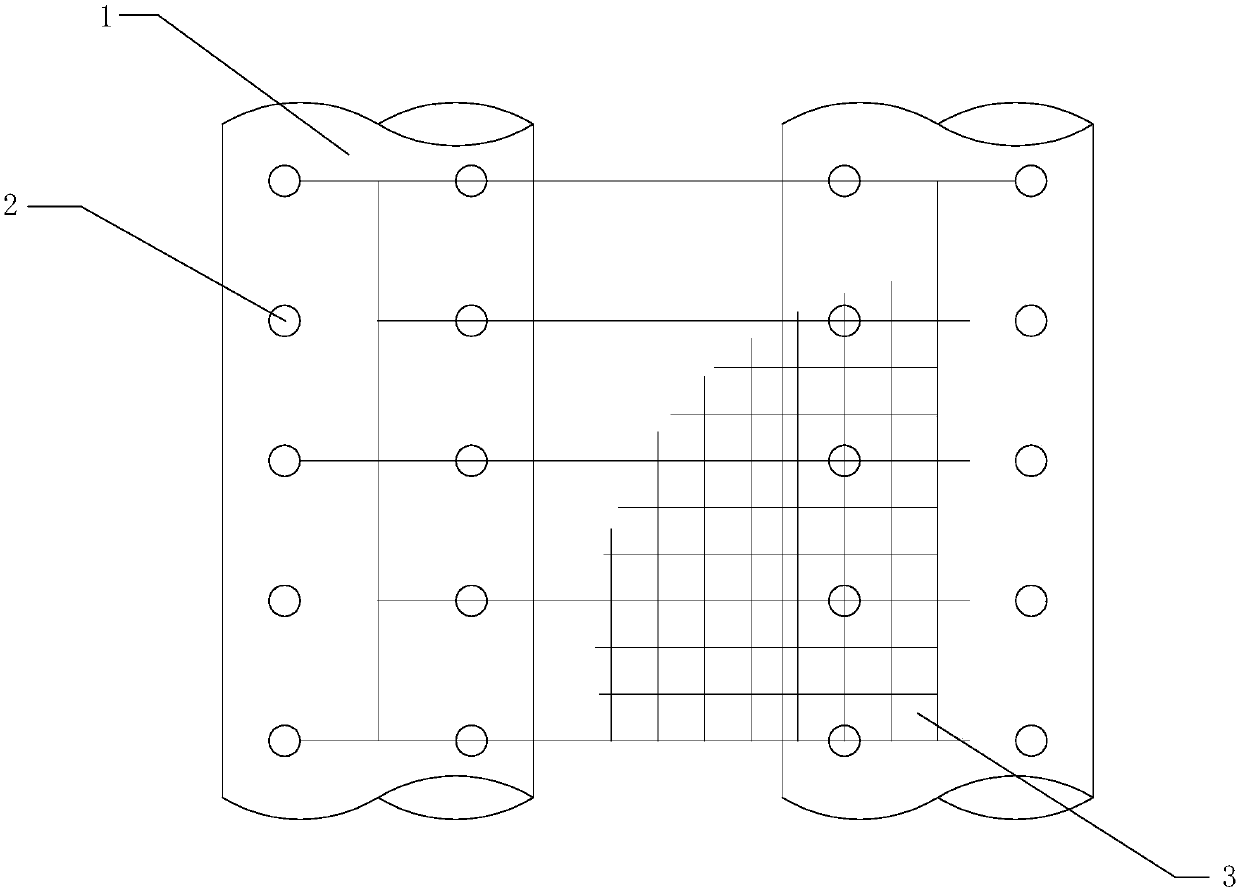

[0033] refer to Figure 1-3 , the present embodiment provides a construction method for molding concrete between retaining piles of a subway station, comprising the following steps:

[0034] (1) Pretreatment is performed on the working surface of the retaining pile 1 . mainly includes:

[0035] 1) Excavation limit chiseling of enclosure pile 1;

[0036] The bored piles for the main enclosure of the station, due to hole reaming and eccentricity during the construction process, part of the enclosure pile 1 structure invaded the boundary of the molded concrete or the boundary of the main structure, resulting in the failure of smooth construction of the molded concrete and the inability of the steel mesh to be laid smoothly. Template could not be installed. Therefore, before constructing the molded concrete, the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com