Expansive agent for concrete and preparation method of expansive agent

An expansion agent and concrete technology, applied in the field of concrete expansion agent, can solve the problems of low mixing ratio, few, and many harmful elements, and achieve the effect of high strength, low cost, and large expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with embodiment further clarifies content of the present invention, but these embodiments do not limit protection scope of the present invention.

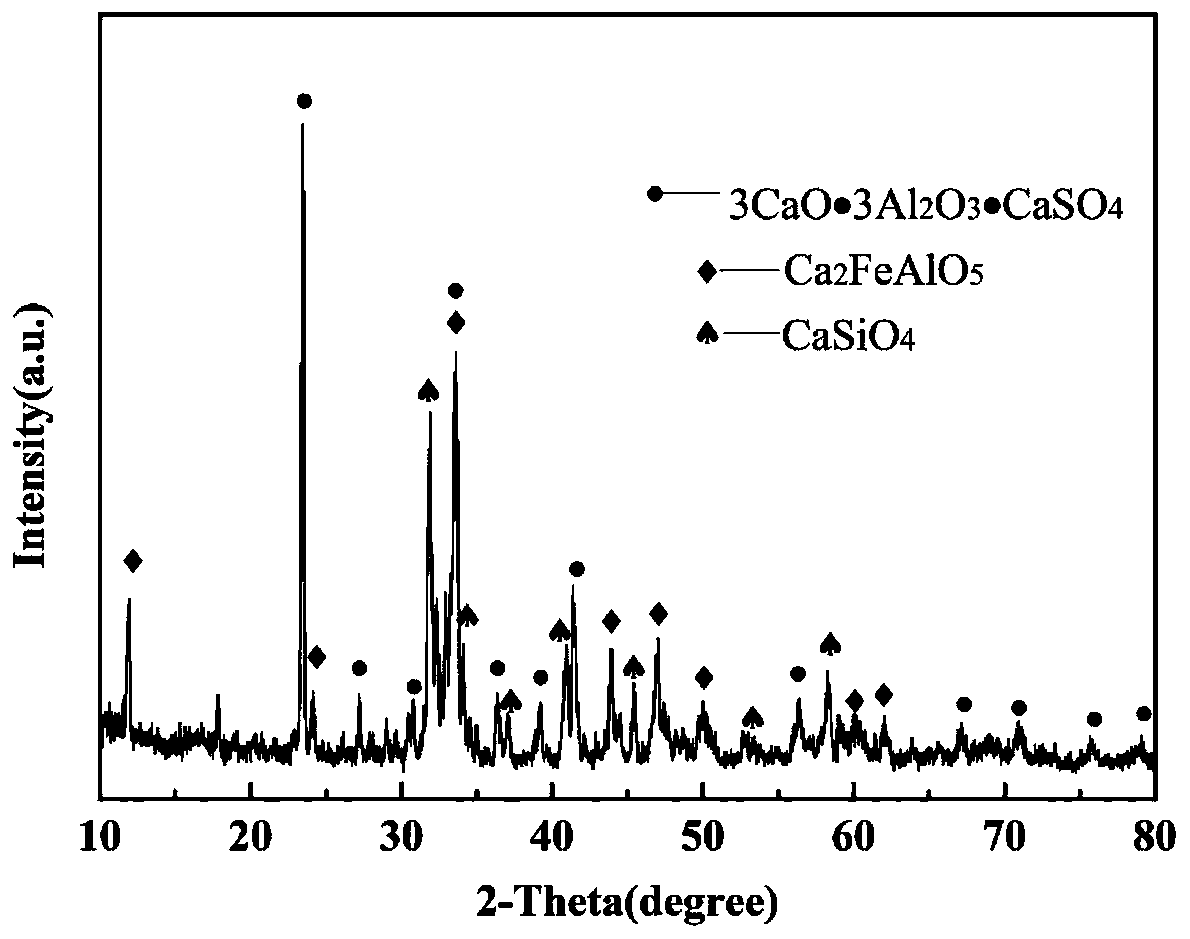

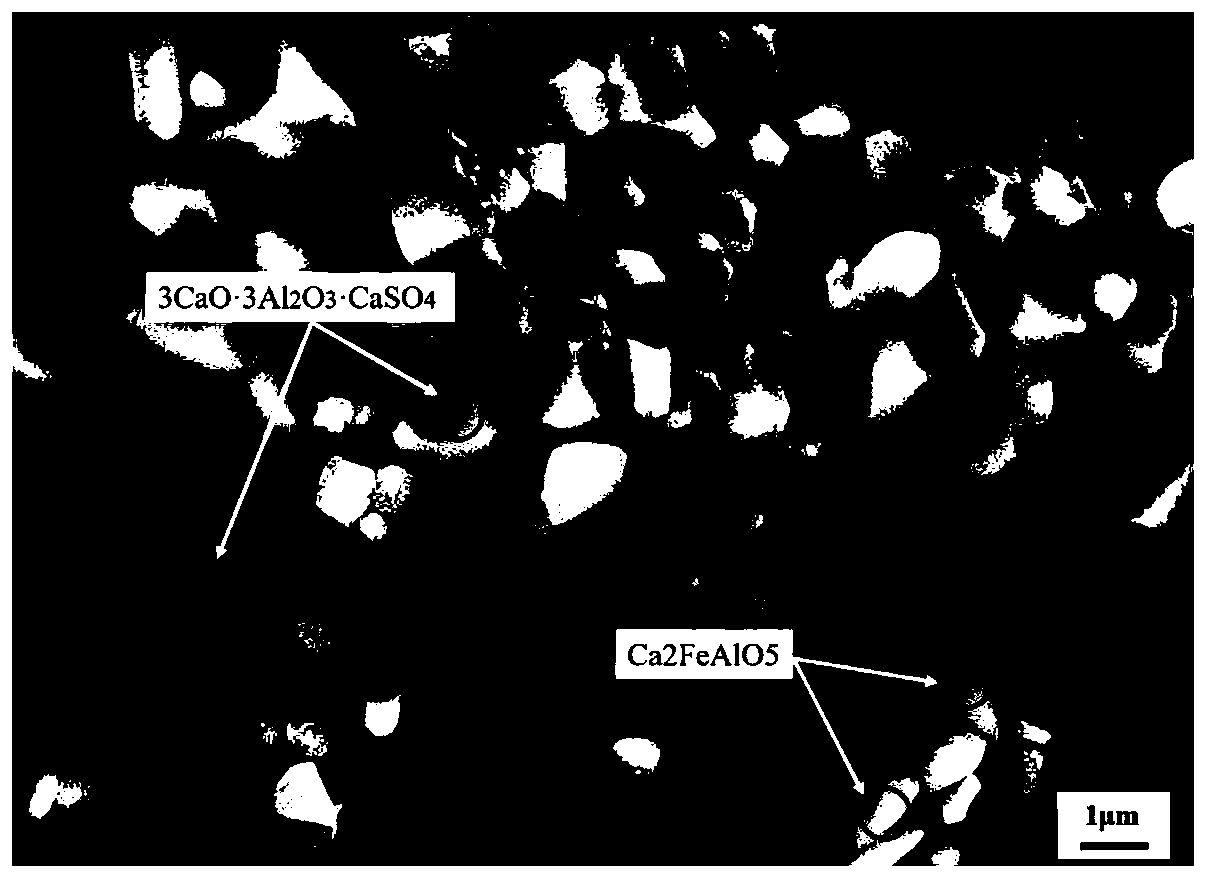

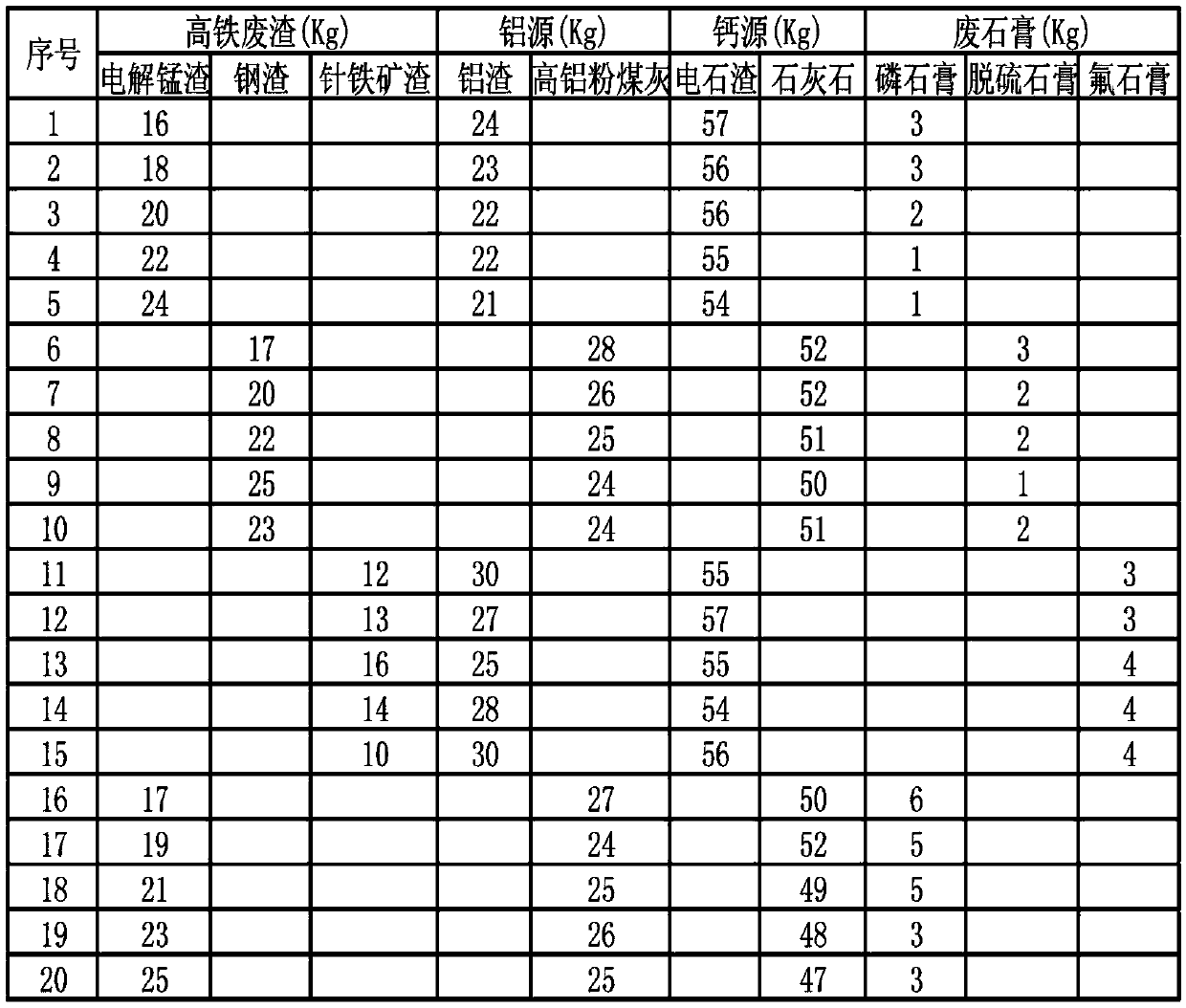

[0027] Preparation of sulfur iron aluminate expansion agent: Weigh each raw material according to the designed formula, select the material: ball: absolute ethanol is 1:2:1, use a planetary ball mill to mix the raw materials evenly and grind them finely. The ball milling speed is 350r / min , After ball milling for 1 hour, take out the slurry, dry it, and pass it through a 200-mesh sieve. Weigh an appropriate amount of the dried slurry and put it into the high-temperature sintering furnace to raise the temperature according to the set program, and then cool down to room temperature with the furnace. Remove the sintered sample. Grind the sintered sample through a 200-mesh sieve, add gypsum according to the designed ratio of gypsum to expanded clinker, and mix evenly to obtain a sulfur-iron-aluminate expans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com