Fe2O3@MXene composite powder and preparation method thereof

A composite powder, fe2o3 technology, applied in the field of wave-absorbing materials, can solve problems such as poor high temperature resistance, high reflection loss, and narrow absorption frequency band, and achieve the effects of low preparation cost, improved wave-absorbing ability, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

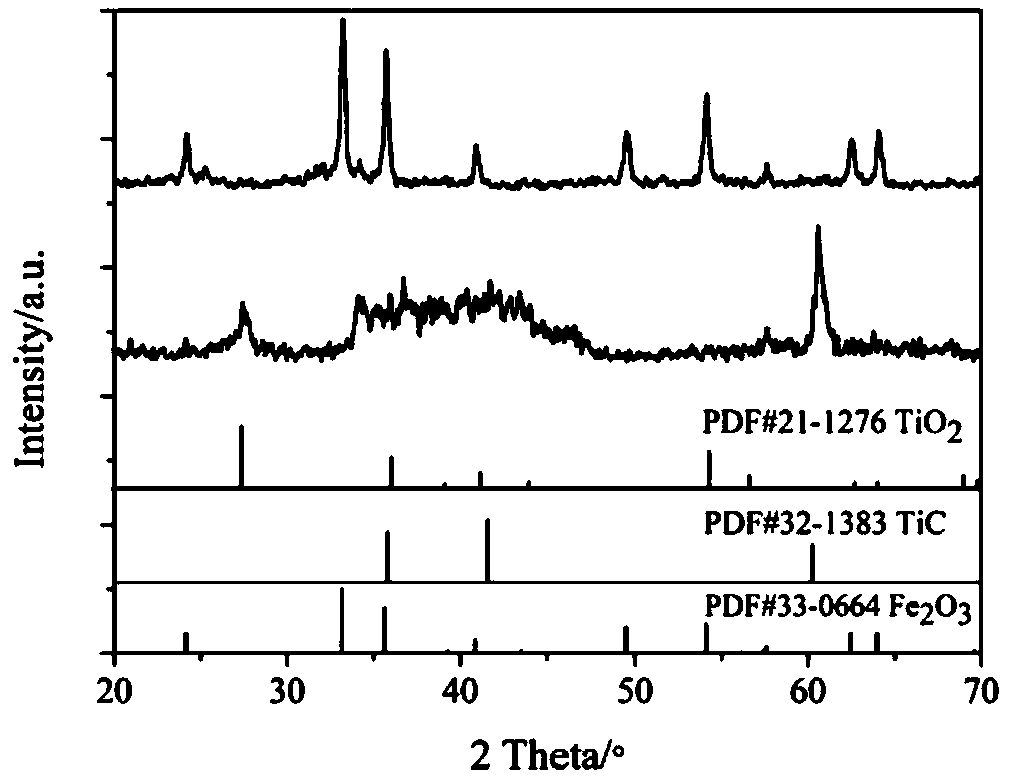

[0044] A kind of Fe provided by the invention 2 o 3 The preparation method of @MXene composite powder comprises the following steps:

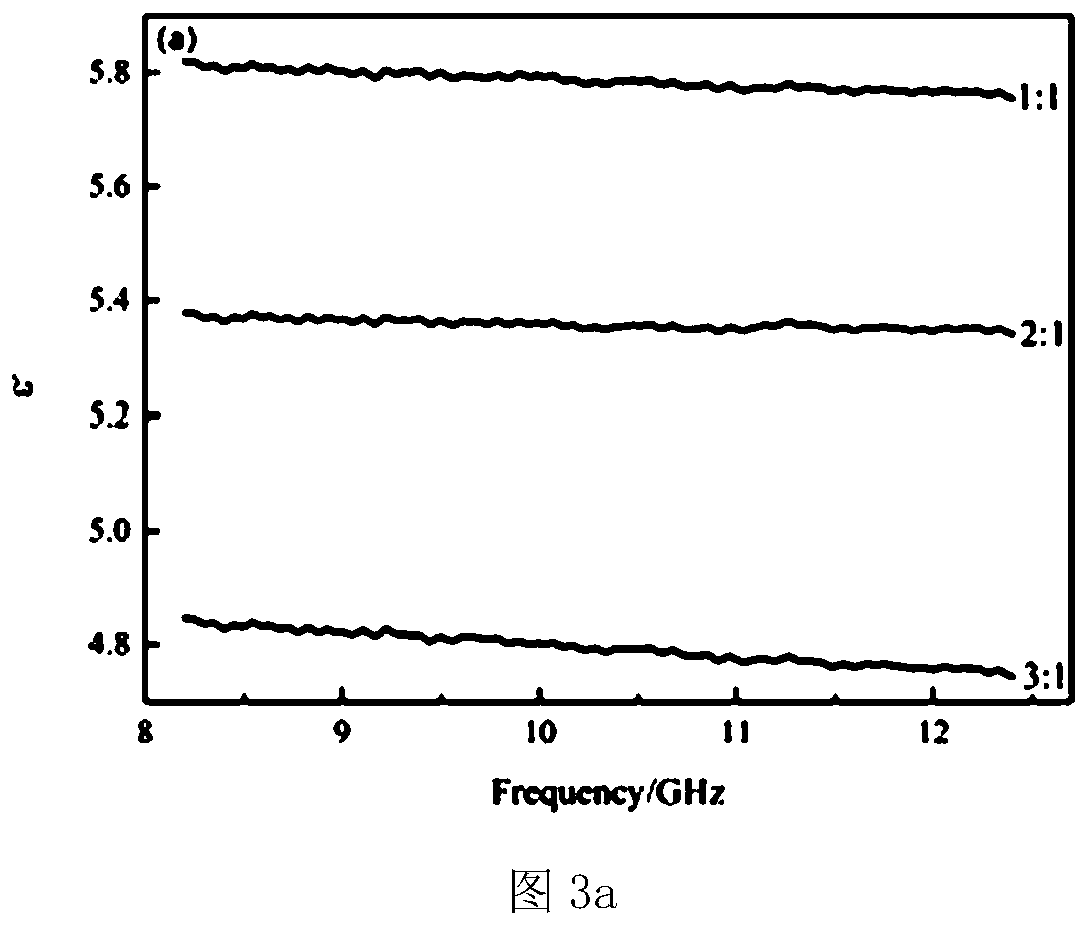

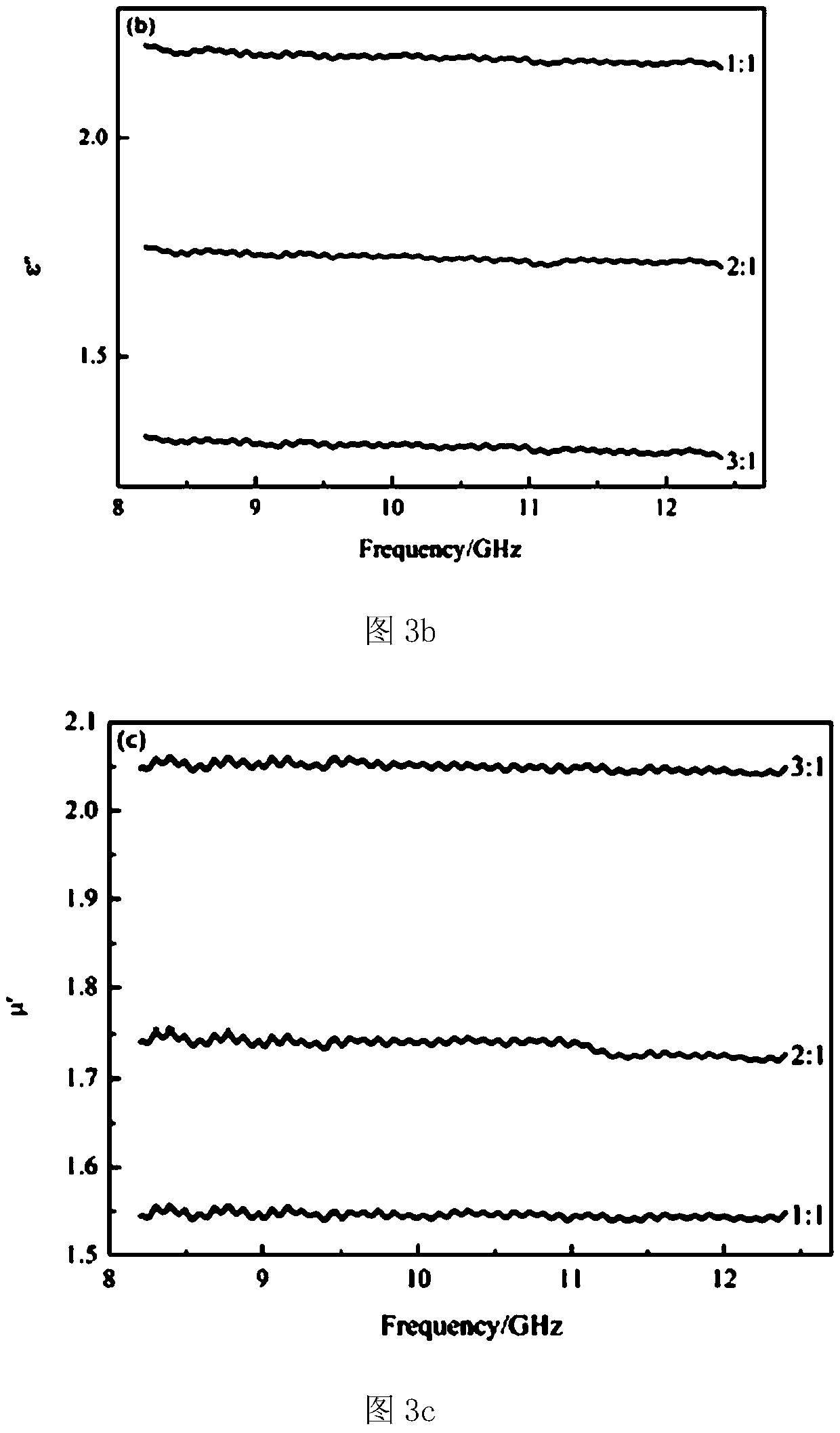

[0045] Step 1, the Fe 2 o 3 Mix with MXene powder at a molar ratio of (1~3):1, and stir at room temperature for 0.5h to make Fe 2 o 3 Mix well with MXene powder;

[0046] Step 2, the mixed composite material is placed at room temperature and dried to constant weight to obtain Fe 2 o 3 @MXene composite powder.

[0047] Wherein, the preparation of MXene powder comprises the following steps:

[0048] S1, weigh 3g of titanium aluminum carbon with an electronic balance, slowly add it to 60ml of hydrofluoric acid with a concentration of 40%, place it on a magnetic stirrer, and stir at a constant temperature of 35°C for 24h;

[0049] S2, ultrasonic cleaning the stirred mixed solution at 35°C for 60 minutes;

[0050] S3, then the ultrasonically cleaned mixed solution was centrifuged four times with deionized water until the pH was neutral, an...

Embodiment 1

[0065] direct mixing

[0066] 1. Preparation of MXene powder

[0067] (a) Weigh 3g of titanium aluminum carbon with an electronic balance, slowly add it to 60ml of hydrofluoric acid with a concentration of 40%, place it on a magnetic stirrer, and stir at a constant temperature of 35°C for 24h;

[0068] (b) Ultrasonic cleaning the stirred mixed solution for 60 min at 35°C;

[0069] (c) Then the ultrasonically cleaned mixed solution was centrifuged four times with deionized water until the pH was close to neutral, and then dried at room temperature to obtain MXene powder;

[0070] 2. Preparation of Fe2O3 powder

[0071] (a) Weigh 60g deionized water and 32g absolute ethanol respectively with an electronic balance, and mix the two as solvent;

[0072] (b) Then weigh 21.014g of citric acid and 40.4g of ferric nitrate and add them into the solvent, place them on a magnetic stirrer and stir to dissolve to configure the precursor, and stir at a constant temperature of 85°C until w...

Embodiment 2

[0077] one-step solvothermal method

[0078] 1. Preparation of MXene powder;

[0079] (a) Weigh 3g of titanium aluminum carbon with an electronic balance, slowly add it to 60ml of hydrofluoric acid with a concentration of 40%, place it on a magnetic stirrer, and stir at a constant temperature of 35°C for 24h;

[0080] (b) Ultrasonic cleaning the stirred mixed solution for 60 min at 35°C;

[0081] (c) Then, the ultrasonically cleaned mixed solution was centrifuged four times with deionized water until the pH was neutral, and then dried at room temperature to obtain MXene powder;

[0082] 2. Weigh 0.168g (1mmol) MXene powder with an electronic balance and add it to 60ml DMF (N,N-dimethylformamide, analytically pure), ultrasonically wash for 2 hours to obtain MXene dispersion, and prepare 3 dispersions of the same composition ;

[0083] 3. Weigh 0.404g (1mmol), 0.808g (2mmol), and 1.212g (3mmol) of Fe(NO3)3 9H2O respectively with an electronic balance, add them to the dispersi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com