Method for treating high-magnesium phosphate tailings by utilizing diethylenetriamine pentamethylene phosphonic acid

A technology of diethylenetriaminepentamethylenephosphonic acid and high-magnesium phosphorus tailings, which is applied in the field of waste resource utilization, can solve the problems of poor decomposition effect and low comprehensive utilization rate of high-magnesium phosphorus tailings, and improve the comprehensive utilization rate. Improvement of utilization rate, phosphorus grade and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

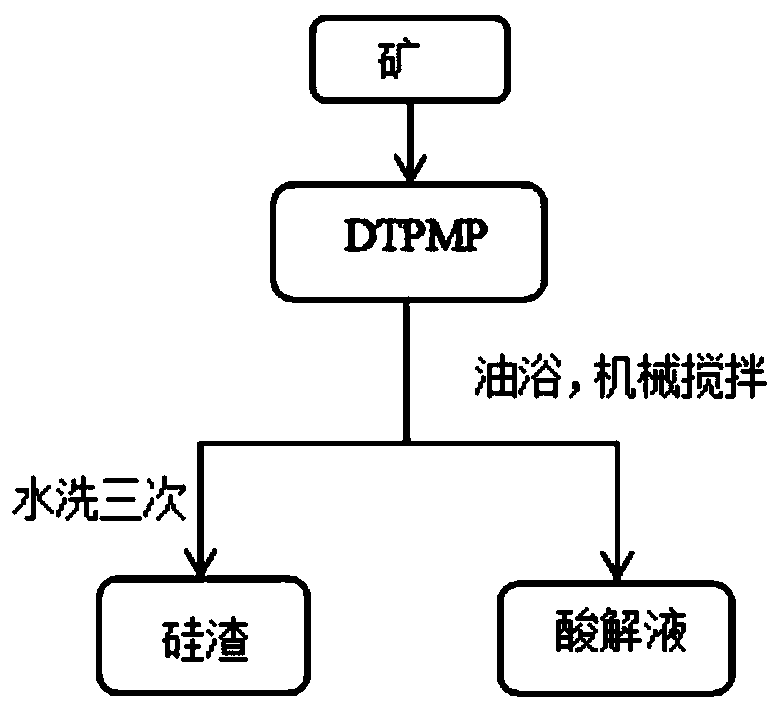

[0021] combine figure 1 As shown, the method of utilizing diethylenetriaminepentamethylenephosphonic acid in this embodiment to treat high-magnesium phosphorus tailings specifically includes the following steps:

[0022] After the pH value of 200g diethylenetriaminepentamethylenephosphonic acid (DTPMP) is adjusted to 1 with ammonia water, the oil bath is heated to 70°C, and then, according to the amount of the total substance of calcium and magnesium in the high-magnesium phosphorus tailings and diethylene triethylene The ratio of the substance amount of amine pentamethylene phosphonic acid is 1.56, adding high-magnesium phosphorus tailings, and stirring and reacting for 90min at a mechanical stirring speed of 100r / min, then filtering while hot, washing with water for 3 times and filtering to obtain The acid hydrolysis slag (silicon slag) is dried to obtain high phosphorus grade tailings.

[0023] For MgO, CaO, P of high magnesium phosphorus tailings in the present embodiment...

Embodiment 2

[0026] combine figure 1 As shown, the method of utilizing diethylenetriaminepentamethylenephosphonic acid in this embodiment to treat high-magnesium phosphorus tailings specifically includes the following steps:

[0027] After the pH value of 200g diethylenetriaminepentamethylenephosphonic acid (DTPMP) is adjusted to 3 with ammonia water, the oil bath is heated to 70°C, and then, according to the amount of the total substance of calcium and magnesium in the high-magnesium phosphorus tailings and diethylene triethylene The ratio of the substance amount of amine pentamethylene phosphonic acid is 1.56, adding high-magnesium phosphorus tailings, and stirring and reacting for 90min at a mechanical stirring speed of 100r / min, then filtering while hot, washing with water for 4 times and filtering to obtain The acid hydrolysis slag (silicon slag) is dried to obtain high phosphorus grade tailings.

[0028] For MgO, CaO, P of high magnesium phosphorus tailings in the present embodiment...

Embodiment 3

[0031] combine figure 1 As shown, the method of utilizing diethylenetriaminepentamethylenephosphonic acid in this embodiment to treat high-magnesium phosphorus tailings specifically includes the following steps:

[0032] After the pH value of 200g diethylenetriaminepentamethylenephosphonic acid (DTPMP) is adjusted to 2.5 with ammonia water, the oil bath is heated to 90 ℃, then, according to the amount of the total substance of calcium and magnesium in the high-magnesium phosphorus tailings and diethylene triethylene The ratio of the substance amount of amine pentamethylene phosphonic acid is 1.56, adding high-magnesium phosphorus tailings, and stirring and reacting for 90 minutes at a mechanical stirring speed of 120r / min, then filtering while hot, washing with water for 5 times and filtering to obtain The acid hydrolysis slag (silicon slag) is dried to obtain high phosphorus grade tailings.

[0033] For MgO, CaO, P of high magnesium phosphorus tailings in the present embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com