Intelligent drilling system based on LabVIEW and application thereof

A drilling and data technology, applied in the automatic control system of drilling, drilling equipment, earthwork drilling and production, etc., can solve the problems of insufficient recognition of working conditions, inability to apply geological drilling, and accident-free diagnosis functions, etc., to reduce program execution time , It is convenient to adjust the drilling process and reduce the economic loss of drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

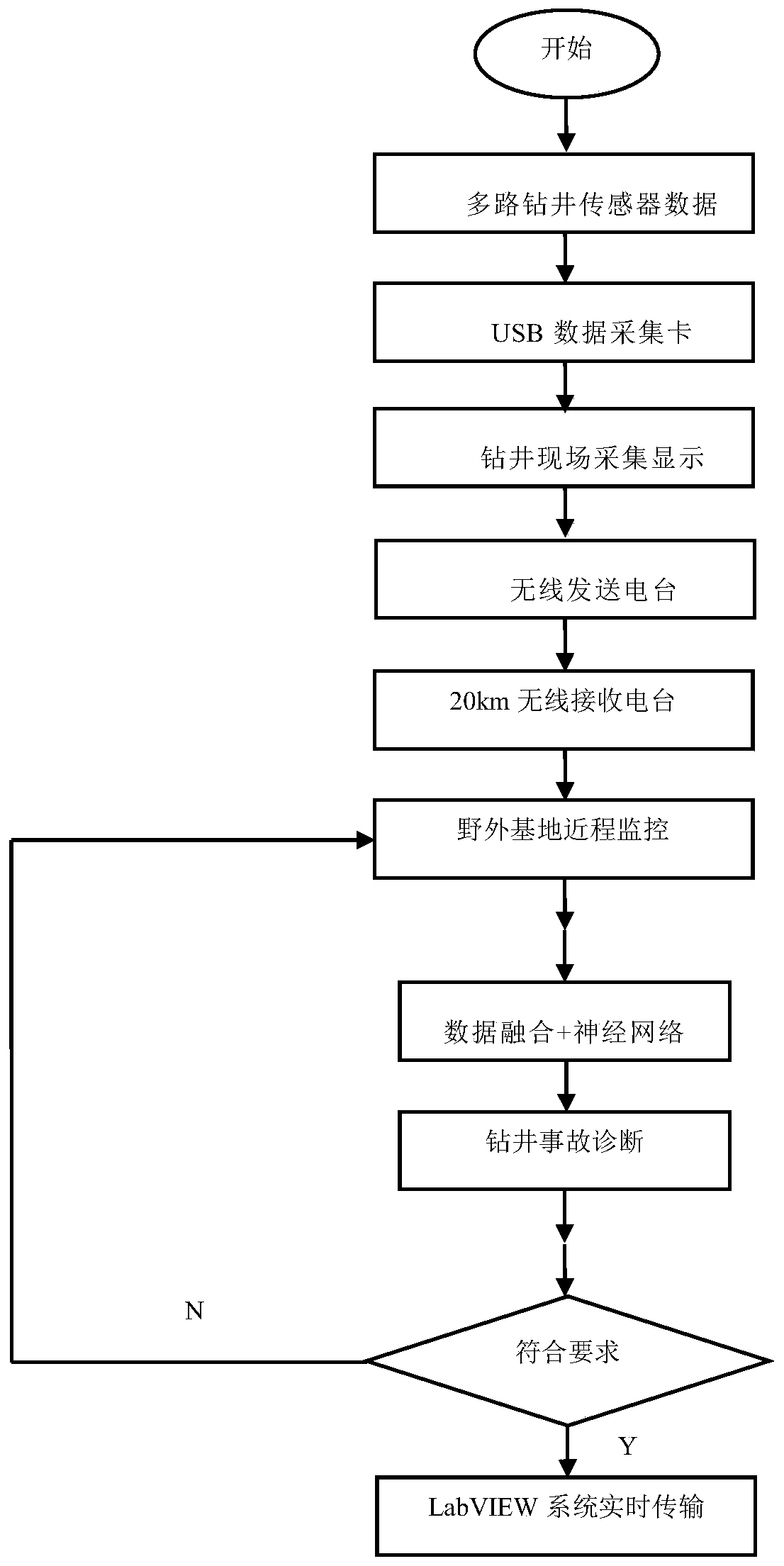

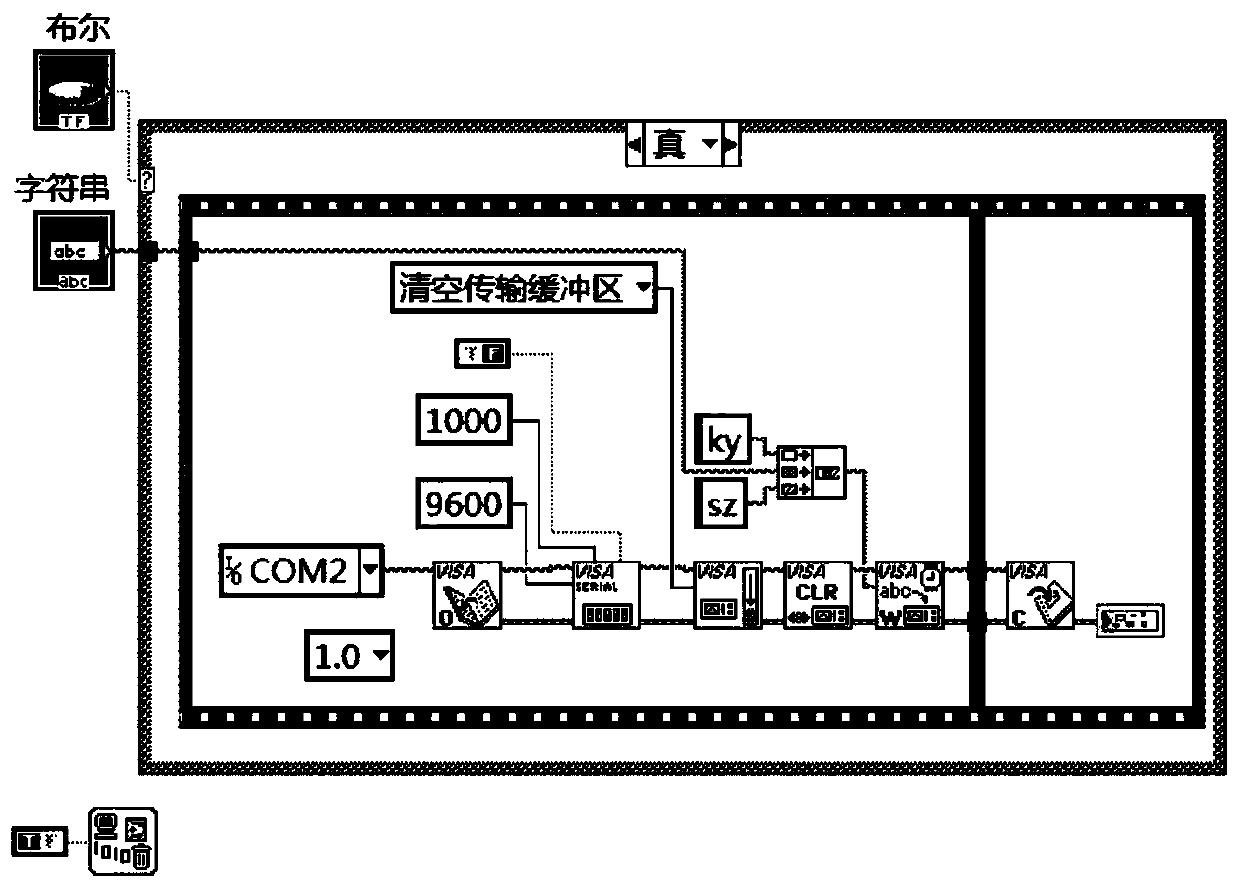

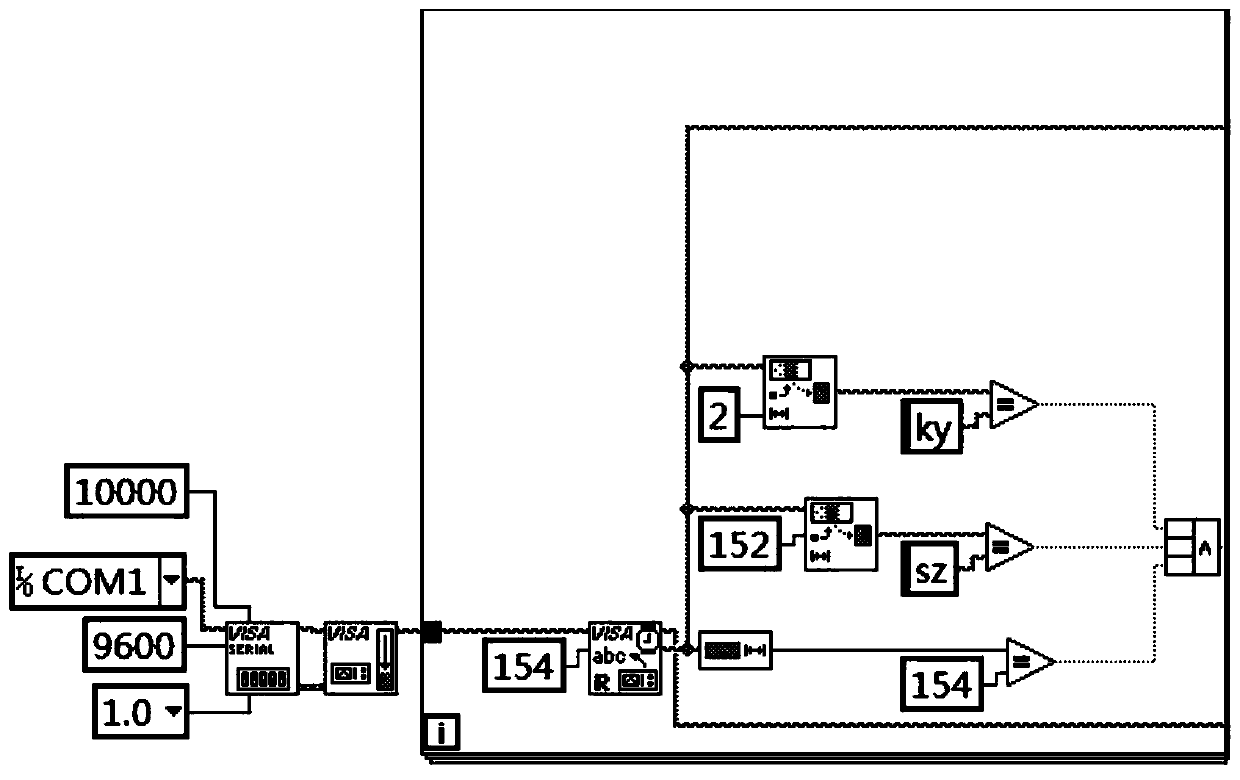

[0100] Embodiment 1. The present invention is applied to the construction site of drilling with sensors installed for detection, such as supporting Wenchuan Branch Drilling WFSD-4 hole drilling sensor data, the rotary speed of the scene, hook height, hook load, standpipe Sensor parameters such as pressure, load-bearing sensor, current, impulse speed, flow rate, temperature, density, and mud pool volume are converted from analog signals of sensors to digital signals through a USB data acquisition card and collected to the drilling site. Due to the poor conditions of the drilling site and high-load production, it is necessary to use a wireless transmitting station to send the field data to a field base with a network and better conditions. For example, a wireless receiving station is used to receive the transmitted sensor signals within 20km. Then through the calculation, analysis and processing of the LabVIEW software platform, the secondary conversion data such as drilling pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com