Loosing detection and early-warning system of large-size screw and screw group

An early warning system and screw technology, applied in the testing of mechanical parts, the testing of machine/structural parts, measuring devices, etc., can solve the problems of inability to detect the tightness degree and the influence of algorithm accuracy, and achieve low maintenance cost and strong adaptability. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

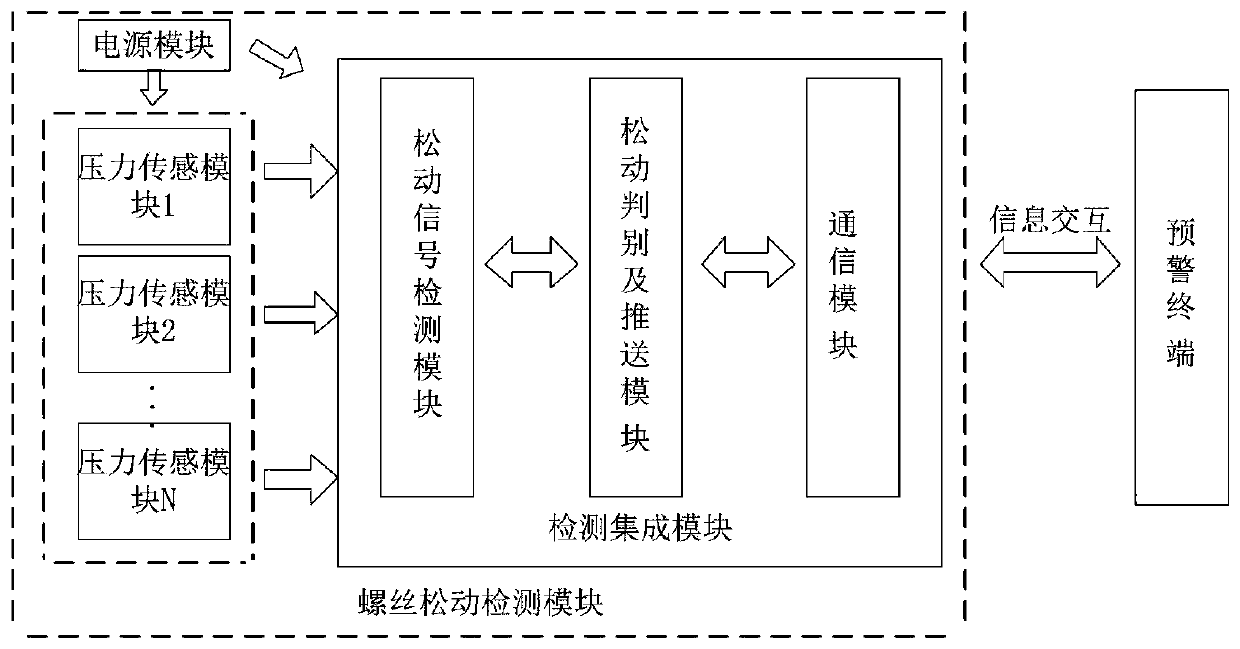

[0029] as Figure 4 Take the large screw shown as an example, install the pressure sensor between the flat washer (or backing plate) and the flange, and take into account the influence of outdoor rainwater, dust and other factors on the screw loosening detection module, collect the loosening signal and judge the loosening and push and communication modules are integrated in a sealed package box, and the power line and signal line are connected to the pressure sensing module through the sleeve; at the same time, in order to save hardware resources, a screw integrated detection module is used to detect multiple screws on a fastened body. Large screws (screw clusters). Large-scale wind turbine towers generally consist of 3 to 4 sections of cylindrical single columns (such as figure 2 (shown) are connected by large screws. When the large screws with a screw loose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com