Combined heat and power generation method and device of solid oxide fuel cell and process heating furnace

A solid oxide, fuel cell technology, used in fuel cell heat exchange, fuel cells, fuel cell additives, etc., can solve the problems of high failure rate, not widely popularized and used, and high investment in gas turbines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

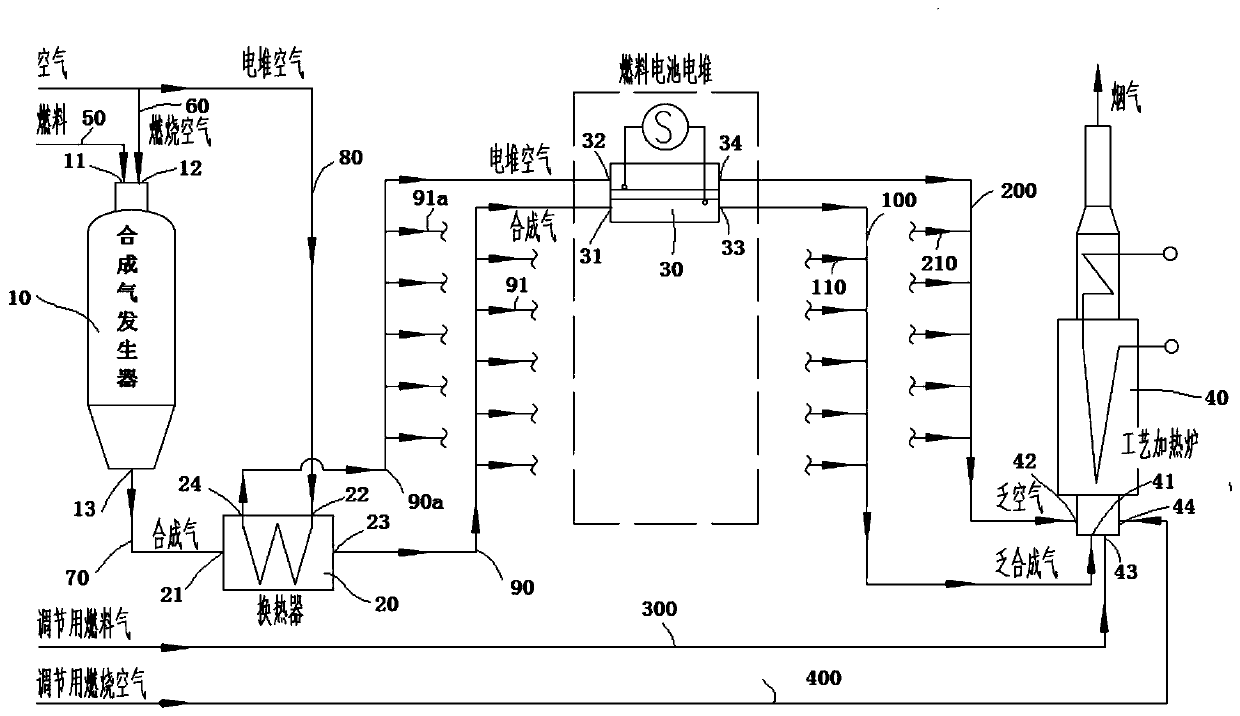

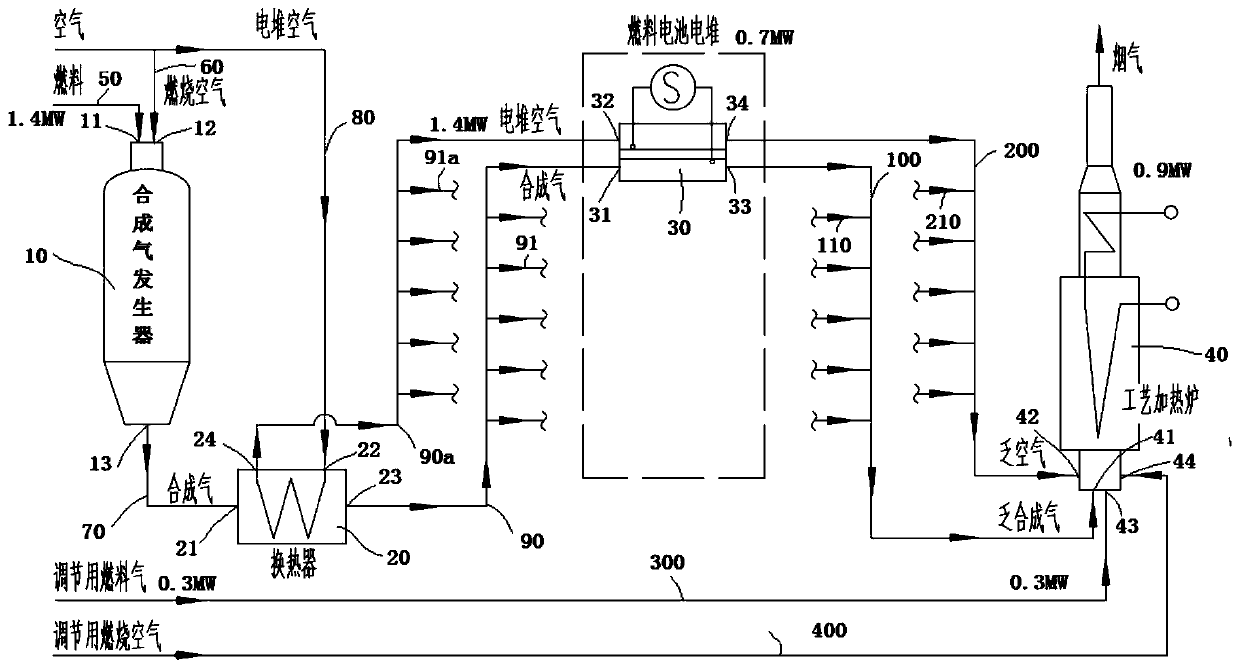

[0027] see figure 1 , figure 1 It is a basic process flow chart of cogeneration of heat and power with solid oxide fuel cell (SOFC) and petrochemical heating furnace.

[0028] figure 1 The solid oxide fuel cell and process heating furnace cogeneration device shown in , consists of a syngas generator 10 , a heat exchanger 20 , several solid oxide fuel cell stacks 30 and a process heating furnace 40 .

[0029] The fuel inlet 11 on the syngas generator 10 is connected to the fuel source through the fuel input pipe 50, the oxidizing medium inlet 12 on the syngas generator 10 is connected to the oxidizing medium source through the oxidizing medium input pipe 60, and the high temperature of the syngas generator 10 The synthesis gas outlet 13 is connected with the high temperature synthesis gas inlet 21 of the heat exchanger 20 through the high t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com