A kind of emc packaging silica gel and application

A technology of silica gel and organosiloxane, applied in the direction of adhesives, etc., can solve the problems of restricting the use of EMC brackets, poor adhesion, and easy peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

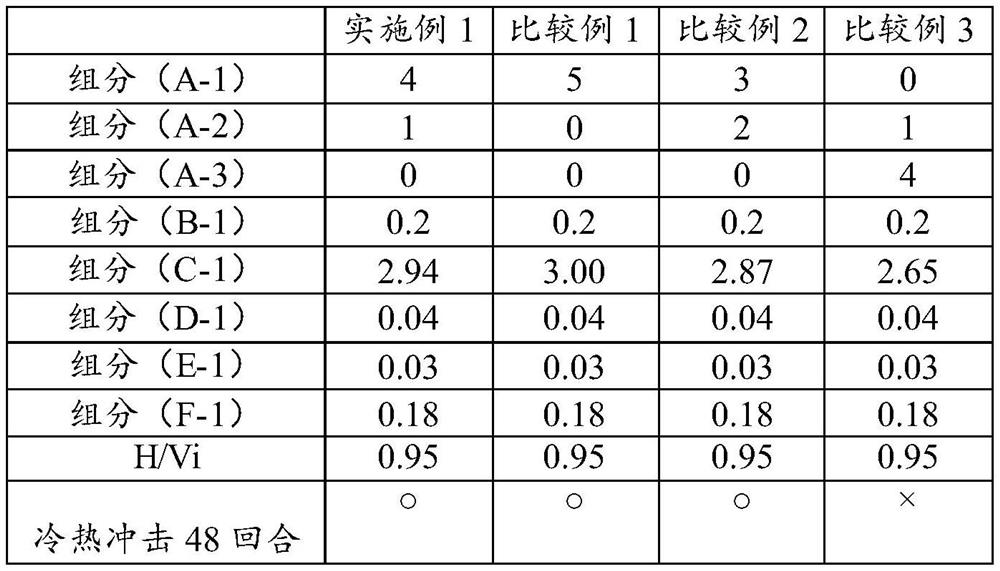

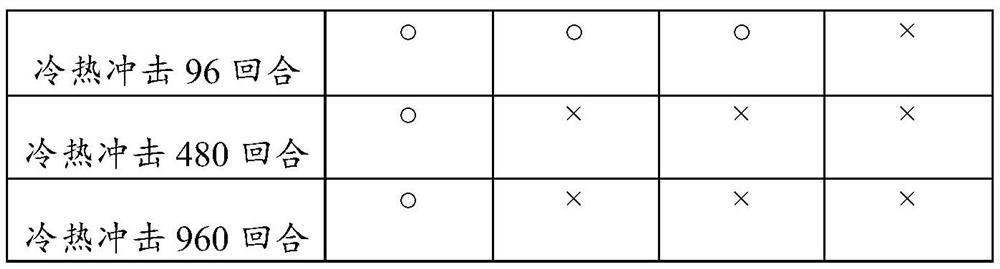

Examples

preparation example Construction

[0079] The present invention has no special limitation on the preparation method of the EMC encapsulating silica gel, which can be obtained by mixing the above raw materials.

[0080] The present invention also provides the application of a kind of EMC encapsulation silica gel in encapsulation EMC support, and described EMC encapsulation silica gel is EMC encapsulation silica gel described above, the present invention injects EMC encapsulation silica gel in the above EMC support, in 70~ Heating at 80°C for 1 to 2 hours, and then heating at 150 to 160°C for 3 to 4 hours can realize the packaging of the EMC bracket.

[0081] The invention provides an EMC encapsulating silica gel, which is made of the following components in parts by weight: organosiloxane A: 1-10 parts; organosiloxane B: 0.1-1 part; organosiloxane C: 2 parts ~6 parts; Custer catalyst: 0.01~0.1 part; Inhibitor: 0.01~0.08 part; Tackifier: 0.05~0.5 part; The organosiloxane A has the chemical formula shown in formul...

Synthetic example 1-1

[0083] Synthesis example 1-1 Synthesis of organosiloxane A-1

[0084]Place 111.84g of 1,3-divinyl-1,1,3,3-tetramethyldisiloxane, 1130.4g of toluene, 473.4g of water, 30g of concentrated sulfuric acid in a reaction vessel, and A mixed solution of 191.73 g of methylvinyldimethoxysilane, 1189.74 g of phenyltrimethoxysilane, and 281.13 g of ethyl orthosilicate was added dropwise at a temperature of °C or lower. After completion of the dropwise addition, the obtained mixture was stirred at 75° C. for 2 hours. Then it was cooled to room temperature, 692.8 g of toluene was added, and the acid was washed away with water.

[0085] The solvent was removed under reduced pressure to obtain an organopolysiloxane resin represented by the following average unit formula:

[0086] (Me 2 ViSiO 0.5 ) 0.12 (MeViSiO) 0.145 (PhSiO 1.5 ) 0.6 (SiO 2 ) 0.135 (OMe) 0.01 (OH) 0.01 ;

Synthetic example 1-2

[0087] Synthesis example 1-2 Synthesis of organosiloxane A-2

[0088] 139.8g of 1,3-divinyl-1,1,3,3-tetramethyldisiloxane, 1090.7g of toluene, 441g of water, 29g of concentrated sulfuric acid were placed in a reaction vessel, and at 30°C A mixed solution of 132.23 g of methylvinyldimethoxysilane and 1487.18 g of phenyltrimethoxysilane was added dropwise at or lower temperature. After completion of the dropwise addition, the obtained mixture was stirred at 75° C. for 3 hours. Then it was cooled to room temperature, 668.5 g of toluene was added, and the acid was washed with water.

[0089] The solvent was removed under reduced pressure to obtain an organopolysiloxane resin represented by the following average unit formula:

[0090] (Me 2 ViSiO 0.5 ) 0.15 (MeViSiO) 0.1 (PhSiO 1.5 ) 0.75

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com