In-situ chemical reactor and combined system of in-situ chemical reactor and nuclear magnetic resonance

A chemical reactor and nuclear magnetic resonance technology, which is applied in the fields of nuclear magnetic resonance analysis, scientific instruments, instruments, etc., can solve problems affecting Xe nuclear magnetic shielding, electron cloud density, and chemical shift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

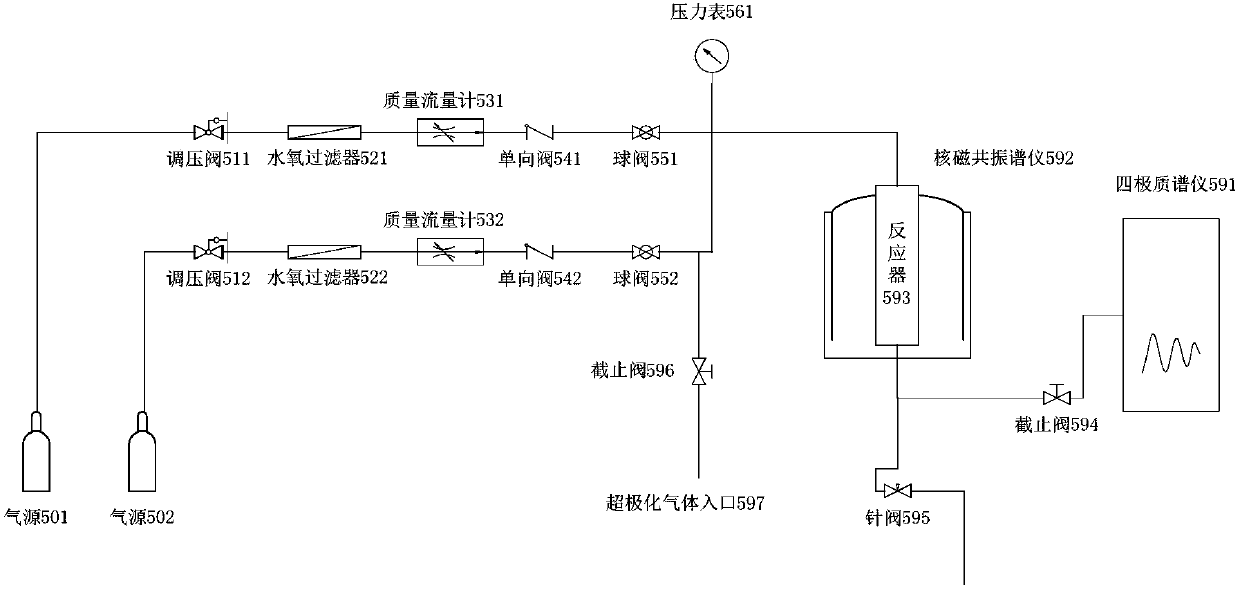

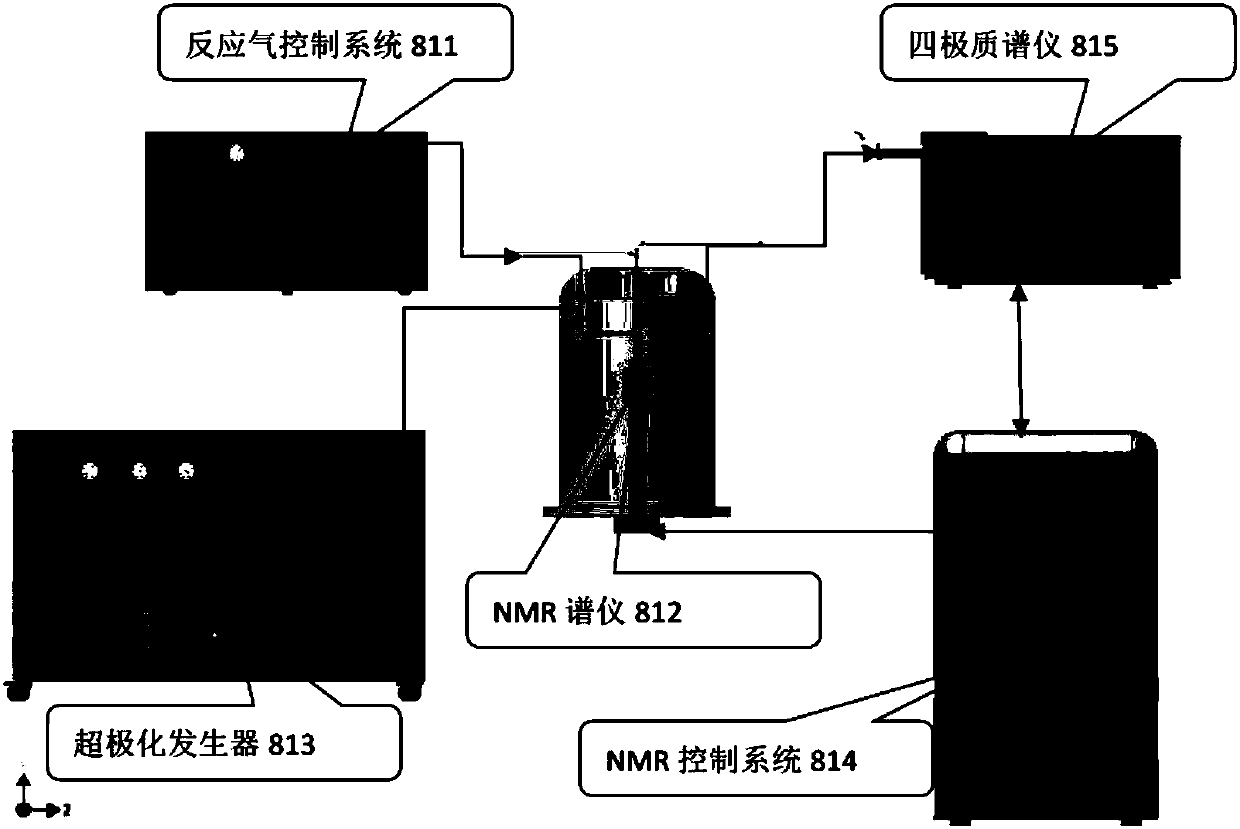

Method used

Image

Examples

Embodiment 1

[0053] A form of realization of the in-situ chemical reactor of the present invention is as follows: Figure 3A with Figure 3B as shown, Figure 3A is the structural diagram of the gas-solid phase reactor (reactor A), Figure 3B It is an exploded view of the composition of the gas-solid phase reactor (reactor A).

[0054] The reactor is a closed straight tube type. The bottom end of the outer tube 601 of the reactor is closed, the top end is open, and the top end has threads. The top end seals the outer tube 601 through a sealing rod 612. The sealing rod 612 is equipped with a rubber sealing O-ring 613, and the sealing rod 612 is sealed together with the outer tube 601 through the fixing bolt 611 of the sealing rod. The sealing rod 612 is equipped with gas inlet and outlet pipelines. The reactor is a nested structure of an inner tube and an outer tube. The gas enters the upper part of the sample through the inner tube, flows out from the bottom after flowing through the s...

Embodiment 2

[0061] Another realization of the above-mentioned chemical reactor is a gas-liquid chemical reactor (reactor B), in which liquid reactants are filled into the outer tube, and its basic structure is similar to that of reactor A, the difference is that the length or shape of the inner tube of the sample tube is different , the reactor is suitable for studying the multiphase chemical reaction system of liquid and gas.

[0062] attached Figure 5A and 5B The structure diagrams of two different gas-liquid reactors are respectively: attached Figure 5A In the reactor shown, the inner tube is 30-40 mm shorter than the inner tube of reactor A. When filling liquid reactants, the bottom end of the inner tube (ie, the gas outlet) is close to the liquid surface of the liquid reactant in the outer tube but does not touch the liquid surface. , such a design makes the flowing gas have less influence on the liquid, and the liquid will not be blown and bubbling by the gas, which basically ha...

Embodiment 3

[0065] This example utilizes hyperpolarized 129 Xe probes are used to study the pore structure changes in porous materials with MFI structure. Using the reactor described in Example 1, the measured substance records the MFI structure material of each different structure at different temperatures 129 Xe NMR spectrum.

[0066] 1. Experimental method

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com